Tag: stability

Achieving Process Stability with Common Cause Variation: Strategies for Success

Published:This article will introduce you to common cause variation, one of the foundational concepts in quality improvement. We’ll explore guidance for the successful use of common cause variation in process improvement.

Read more »

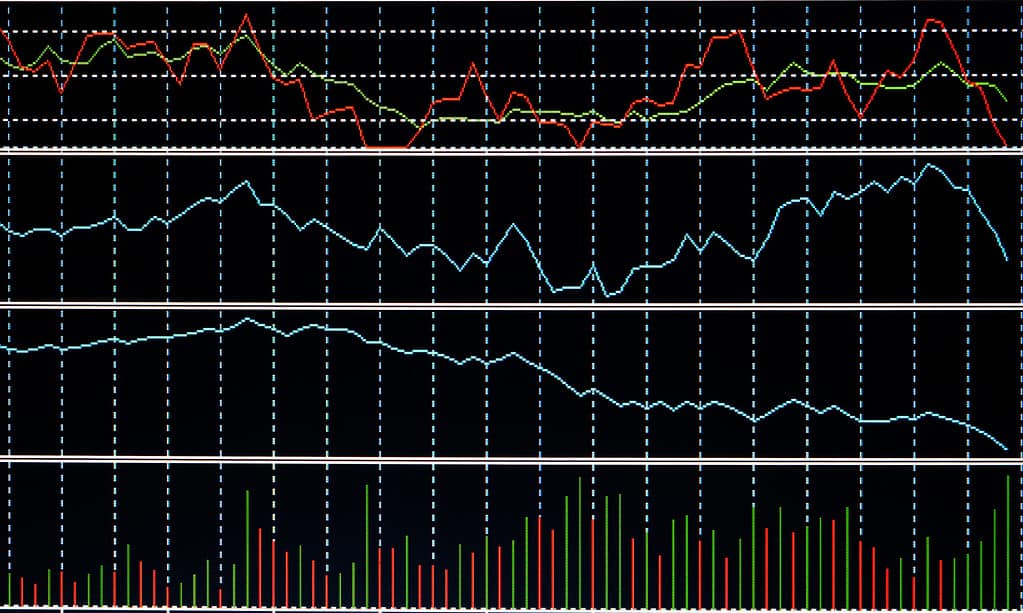

Assessing Process Stability: Techniques and Tools

Published:Have you ever wondered why your doctor may keep you waiting in the waiting room or why you have to fast before doing a blood test? Let’s see if Lean Six Sigma can give you an answer.

Read more »

Process Stability: Minimizing Variation While Increasing Efficiency

Published:In Six Sigma, process stability is extremely important to efficiency and productivity. With a stable process, you have predictability, and quotas can be met.

Read more »

What Is a Stable Process?

Published:Process stability is one of the most important concepts of the Six Sigma methodology, or any quality improvement methodology for that matter. Stability involves achieving consistent and, ultimately, higher process yields through the application of an improvement methodology. Does a process need to be stable in order for a black belt to improve it? Try […]

Read more »

A Simple Model of a Variance Stable Process

Published:Most fairly accurate descriptions of equipment and/or process lifetimes assume that failure rates follow a three period I II III “bathtub-curve pattern” where failures/errors: I – Decrease during the debugging or improvement time period. II – Remain relatively constant and at their lowest levels during the normal equipment or process operating period. III – Increase […]

Read more »