Tag: root cause analysis

The Benefits of a Force Field Analysis: Master Changes in Your Processes

Published:One of the most famous sayings in the Star Wars films is May the Force be with you. This saying may also apply to making changes in your organization. Let’s see what forces you need to identify and deal with when using a force field analysis to manage change.

Read more »

Getting to the Bottom of Your Problem: How to Use the 5 Whys

Published:Asking “Why?” may be a favorite technique of your 3-year-old child in driving you crazy, but it could teach you a valuable Six Sigma quality lesson. The 5 Whys is a technique used in the Analyze phase of the Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) methodology. It is a great Six Sigma tool that […]

Read more »

Causal Loop Diagrams: Little Known Analytical Tool

Published:Sometimes it is easy to get into a rut when it comes to doing analysis. It can be hard to stray from those same time-tested analytical tools used in the Six Sigma methodology. The process map, failure modes and effects analysis, cause-and-effect matrix, and fishbone diagram are like well-used tools that feel comfortable […]

Read more »

Lean Six Sigma to Reduce Excess and Obsolete Inventory

Published:Excess and obsolete inventory write-offs are chronic supply chain problems costing businesses billions of dollars each year. Unfortunately, improvement projects that are deployed to eliminate these problems often have a short-term focus. In other words, the current levels of excess and obsolete inventory are usually addressed, but not the root causes of the […]

Read more »

Corrective Action: Eliminating Nonconformity Permanently

Published:Corrective action is the process, known as a corrective action plan (CAP), of taking the appropriate steps to identify the root cause of a problem and implementing a solution that corrects the root cause to prevent its recurrence. The aim is to improve the processes in place within an organization so that problems […]

Read more »

Root Cause and Failure Analysis (RCFA): How to Fix Production Issues

Published:In a fiercely competitive market reacting swiftly to product or process failures, determining the true root cause and implementing change limits financial and reputational damage. Utilising root cause and failure analysis methodology is your gold standard for robustly preventing future failures.

Read more »

The Difference Between Correction and Corrective Action in Business Problem-Solving

Published:Problems are going to arise in business, but the companies that succeed in the long term are those that find the true causes of those problems and find ways to keep them from happening again. When an issue occurs, the inclination is to stop it quickly. While this is fine, it is important […]

Read more »

Red X: Identifying Causes of Variation

Published:Red X is an anti-hero and a former “villain identity” employed by Robin of Batman and Robin fame. No, that’s not right. Red X is really a problem-solving methodology developed by Dorian Shainin. Let’s explore this a little further.

Read more »

Using Paynter Charts to Explore Process Performance

Updated:Get a quick primer on Paynter charts, a graphical method for comparing data regarding sub-groups. We look at how Paynter charts compare to KPI data and Pareto charts as well as the benefits of creating and reviewing Paynter charts.

Read more »

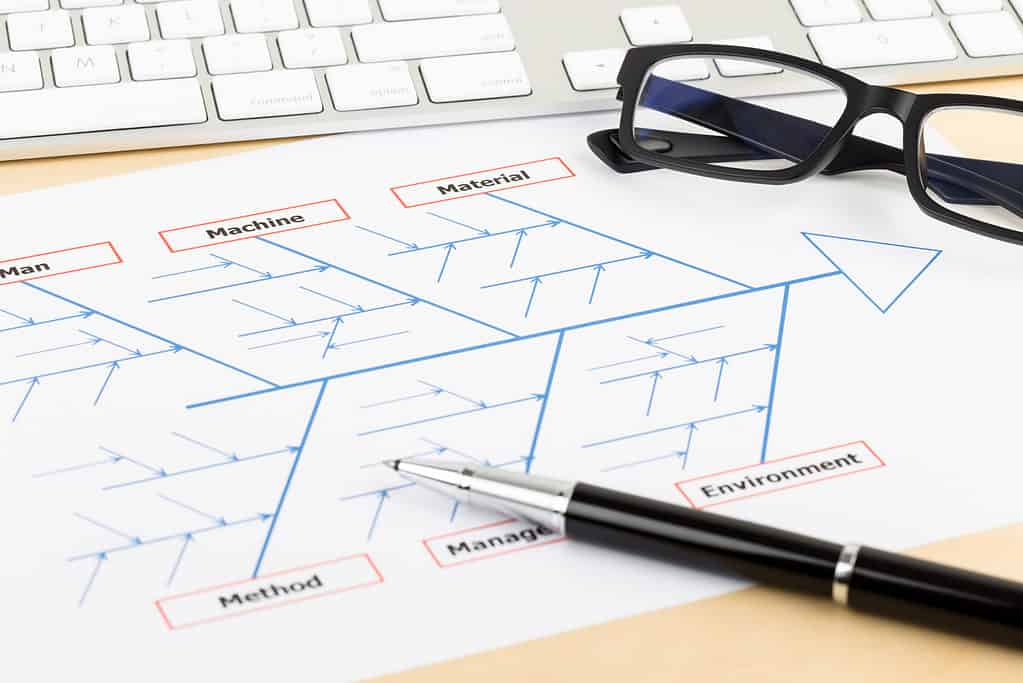

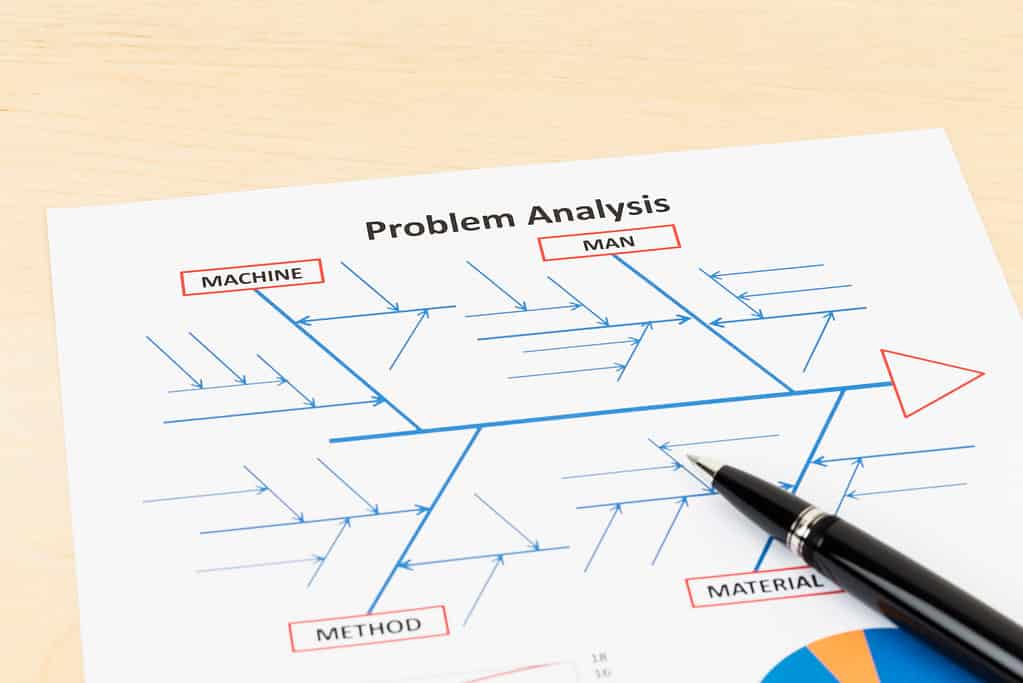

Fishbone Diagrams: A Powerful Tool for Root Cause Analysis

Updated:Fishbone diagrams are used to drill down to the root cause of a problem. The diagram looks like the bones of a fish, where each main bone represents a possible category of root cause, and subsequent drilling down is shown as smaller and smaller bones.

Read more »

6W Methodology: Master Problem Analysis With Ease

Published:6W? 5W1H? 5W? The bigger question is, how do you make sure you’re asking the right questions to guarantee you properly solve your problem or execute your project?

Read more »

Understanding Poka-Yoke: Eliminating Defects with Proactive Measures

Updated:What is poka-yoke? Have you ever accidentally microwaved your face? No? You’ve never opened the microwave door while it was cooking and accidentally exposed your face to microwave energy? I know that you haven’t because whenever you open the door, the microwave stops running. There is a switch that triggers when the door is opened […]

Read more »

Root Cause Analysis: Integrating Ishikawa Diagrams and the 5 Whys

Updated:Root cause analysis (RCA) is a way of identifying the underlying source of a process or product failure. As such, then the right solution can be identified. RCA can progress more quickly and effectively by pairing an Ishikawa diagram. You can also use the scientific method in the form of the well-known plan-do-check-act (PDCA) cycle […]

Read more »

Up Close with William B. Wark

Published:Wark will be presenting on the role of the CSB and the lessons learned from its investigations during a keynote address at iSixSigma’s Energy Forum for Process Excellence on May 17 in Houston. In an interview with iSixSigma Senior Editor Kirsten Terry, Wark offered a preview of some of the topics he will cover during […]

Read more »

Call vs. Online Chat: Switching Volume from One Channel to Another

Published:An iSixSigma Discussion Forum exchange involved the manager of a call center who was interested in eliminating her organization’s “online chat” channel of communication and have all contact flow through the phones instead. However, she wanted to see if she could make an apples-to-apples comparison between the online chat and phone channels, given that they […]

Read more »

How to Revive Your Lean Six Sigma Deployment

Published:The Six Sigma world is filled with stories reiterating the importance of leadership focus when implementing Lean Six Sigma. However, the continuous improvement landscape is also littered with examples of Lean Six Sigma programs that were implemented in full force to start with and then were slowly abandoned after they had spread to other departments […]

Read more »

Effective Brainstorming: Building an Opportunity Matrix

Published:Manufacturing facilities often are faced with major challenges when it comes to large-scale process improvement. Improving yields at a large manufacturing plant – one that produces millions of pounds of product annually – might require modifications for every step in its process: production equipment, maintenance strategies, operational procedures, process control strategies and analytical support strategies, […]

Read more »

DFSS Drives Results for Financial Services Firms

Published:Lean Six Sigma remains a popular and effective tool to improve efficiency in financial services operations. However, many financial institutions are finding that identifying and reducing incremental defect variability does not fully maximize the full spectrum of improvement opportunities. To achieve a larger return on investment, many organizations are turning to Design for Six Sigma […]

Read more »

Reducing Misdirected Calls in Automated Payment Systems

Published:While working on a maintenance project for a large U.S. telecommunications firm, information technology company Infosys Technologies Ltd. discovered that an unacceptably high percentage of calls in the clients’ automated payment system were being routed to the call center agents. The team conducted a DMAIC project, outlined here, to reduce the number of misdirected calls. […]

Read more »

Thinking Two Moves Ahead with Analytical Tools

Published:Considering the performance of the stock market over the past few years combined with current economic conditions, many financial institutions are analyzing their processes for improvements. Unfortunately, the majority of process improvement tools available to Six Sigma practitioners – such as cause-and-effect diagrams, Pareto charts, histograms and scatter plots – have been used for analyzing […]

Read more »

Six Sigma for Software – More Than a New Tool

Published:We need to fundamentally change what’s going on in Software. FAST! Defects, long cycle times, poor estimation, missed targets and project cancellations are stripping away profits and our ability to satisfy and retain customers. It’s occurring in Software Development companies, Embedded Product Software (Firmware), and Business Application Software. And, it’s happening in all industry segments. […]

Read more »

Developing E-Learning the Six Sigma Way

Published:Your e-learning development program may well be in trouble, and applying the Six Sigma methodology might be the solution. In this real-world Six Sigma – play-by-play – case study about e-learning development, you will learn from the Black Belt what tools were used throughout the DMAIC (Define, Measure, Analyze, Improve, Control) phases of a project […]

Read more »

ITIL and Six Sigma Make a Winning Combination for IT

Published:The Information Technology Infrastructure Library (ITIL) and Six Sigma have both been successfully employed to improve the quality of information technology (IT) services. Often the two approaches, although distinctly different but with a common focus on customer satisfaction at their core, are used independently of each other. Fortunately many organizations are coming to realize the […]

Read more »

Going Beyond the 5 Whys

Published:“So what?” That’s all your CEO has to say after you present your latest Lean Six Sigma triumph. You gaze out over a deafeningly silent boardroom. Your team is stunned. While you try to comprehend the CEO’s demoralizing response, the other managers and administrators chime in: “Yeah, so what?” The above scenario might be an […]

Read more »