Tag: Quality

Understanding the Concept of Quality

Published:Quality is one of those words and concepts that have many meanings. Let’s review the concept and discuss the different definitions associated with the term. It refers to the degree of excellence or superiority of something, often concerning its intended purpose or function. Further, it is a measure of how well something meets its specifications […]

Read more »

Mastering Gage R&R: Key Steps for a Successful Study

Published:You want to make good data-driven decisions, but can you trust your data? Is the measurement system you used to gather the data giving you precise and consistent measurements? A Gage R&R study will answer your questions.

Read more »

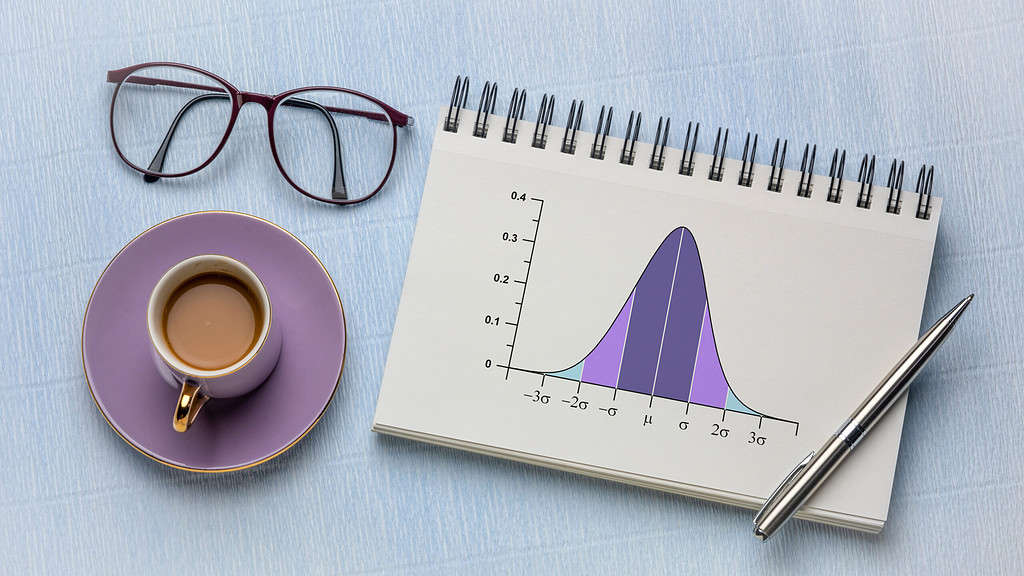

Common Cause vs. Special Cause Variation: What’s the Difference?

Published:Common cause vs. special cause variation, aren’t they the same thing? At first glance, you’d be allowed to think so. However, as with any part of the production cycle, there is a reason for these two measurements to exist. So, let’s dive right into what makes these variations different, and how to identify and benefit […]

Read more »

Pooled Standard Deviation: How Do You Calculate It?

Published:How do you calculate the overall standard deviation of multiple groups or samples? You can’t just add them up and divide by the number of groups, like you do with averages. Let’s see how we can do it correctly.

Read more »

Part Submission Warrant (PSW): Understand How This Document Fits Into PPAP

Published:In today’s competitive business environment, maintaining a high level of quality has become vital to a company’s success. It is imperative that suppliers provide quality parts that meet customer requirements the first time and every time.

Read more »

A Comprehensive Guide to Input-Process-Output Models

Published:Creating and mapping business process models can sound like a daunting task with little tangible value. With input-process-output models, we debunk these myths and introduce a versatile, straightforward methodology that can be used to transform your business.

Read more »

Critical To Quality: The Key to Meeting Customer Expectations

Published:Critical of quality is the path to customer satisfaction. Learn how Critical to Quality impacts the ability to satisfy your customer, the benefits of addressing CTQ related issues, and see an example.

Read more »

Streamlining Six Sigma Projects with the 7 QC Tools

Published:The seven basic tools in my home tool chest are a hammer, screwdriver, wrench, saw, drill, pliers, and duct tape. What basic QC tools do you have in your continuous improvement tool chest? Let’s check it out.

Read more »

Quality Program Report (QPR): Guaranteeing You Hit the Mark

Published:It is important to regularly check if your processes are operating as optimally as they could be. If not, actions should be taken for improvement. For this to be appropriately determined, you can create a QPR.

Read more »

The Hidden Factory: Understanding the Unseen

Published:You claim your process yield is 98%. Are you sure? Have you considered your hidden factory? Let’s find out why you should.

Read more »

Cost of Quality: Not Only Failure Costs

Published:When calculating the business case for a Six Sigma project, the cost of poor quality (COPQ), which is the cost caused by producing defects, is a commonly used concept. Within the total amount of quality cost, however, COPQ represents only a certain proportion. Costs do not result from only producing and fixing failures; […]

Read more »

Ensuring Excellence from the Start: The Role of Incoming Goods Inspection

Published:An in-depth look at how IGI can help businesses become more efficient, profitable, and less wasteful by helping managers keep track of incoming good compliance issues while ensuring incoming goods meet quality standards set by the company.

Read more »

Understanding Customer Needs: The Importance of Quality Targets

Published:Understanding what quality targets are and how to center product uniformity around them is a helpful step in overall process improvement, ultimately leading to increased profits and customer satisfaction rates.

Read more »

Deming’s 14 Points: A Blueprint for Achieving Quality and Productivity in Business

Published:Deming’s 14 Points provide a roadmap to transform American Business and increase productivity and competitive position. Without W. Edwards Deming, modern quality improvement might not exist. If you have never heard of Dr. Deming or his 14 Points for Management, welcome aboard. If you have, get ready to reacquaint yourself. What Are Deming’s […]

Read more »

Exploring the Path to Achieving World-Class Quality

Published:Achieving world-class quality isn’t something every organization can do, because so much of what makes it possible cannot be taught. It boils down to mindset and certain character traits that some people have, some people don’t. Do you?

Read more »

Quality Operating System (QOS): Delivering Constant Quality

Published:With increasing competitive and market pressures, understanding customer requirements and delivering high-quality products, processes and services has never been more important. By implementing a Quality Operating System, you can ensure that quality improvement is every employee’s responsibility and focus.

Read more »

Defect Prevention: Reducing Costs and Enhancing Quality

Published:“Prevention is better than cure” applies to defects in the software development life cycle as well as illnesses in medical science. Defects, as defined by software developers, are variances from a desired attribute. These attributes include complete and correct requirements and specifications as drawn from the desires of potential customers. Thus, defects cause […]

Read more »

Acceptable Quality Level (AQL): Eliminate Defects with Smaller Sample Sizes

Published:The only acceptable quality level should be zero defects. But that’s not always the case. Let’s learn what an acceptable quality level or limit is all about.

Read more »

Average Outgoing Quality: Minimize Defects and Guarantee Quality

Updated:We have all heard the phrase “garbage in, garbage out.” AOQ is defined as the expected average quality level of an outgoing product for a given the value of incoming product quality.

Read more »

Understanding Poka-Yoke: Eliminating Defects with Proactive Measures

Updated:What is poka-yoke? Have you ever accidentally microwaved your face? No? You’ve never opened the microwave door while it was cooking and accidentally exposed your face to microwave energy? I know that you haven’t because whenever you open the door, the microwave stops running. There is a switch that triggers when the door is opened […]

Read more »

B10 Life: Engineering Products for Reliability

Published:As competitive and market pressures increase, having a clear understanding of product reliability, service life, and expected failure rate is crucial. We explore how by utilising B10 life, we can optimise our product development and satisfy our customer requirements.

Read more »

How House of Quality Shapes Product Excellence: Meet Your Customer’s Needs

Updated:House of Quality? No, this is often referred to as a House of Pain because of the effort needed to complete one. Let’s see if we are just being overly pessimistic.

Read more »

Defects per Opportunity (DPO): Get Context for the Flaws in Your Processes

Updated:Defects per opportunity, or DPO, refers to the number of defects that occur in relation to a given number of opportunities for which an error could occur. Let’s consider some of the benefits of measuring and monitoring DPO.

Read more »

Sigma Performance Levels From One to Six Sigma: Get the Most Out of Your Processes

Published:When learning about Six Sigma, it may help to consider these charts. These detail how Sigma Performance Levels relate to defects per million opportunities (DPMO), and some real-world examples. Sigma Performance Levels Table Sigma Performance Levels – One to Six Sigma Sigma Level Defects (or Errors) Per Million Opportunities (DPMO) Yield (or Produced […]

Read more »