Tag: control chart

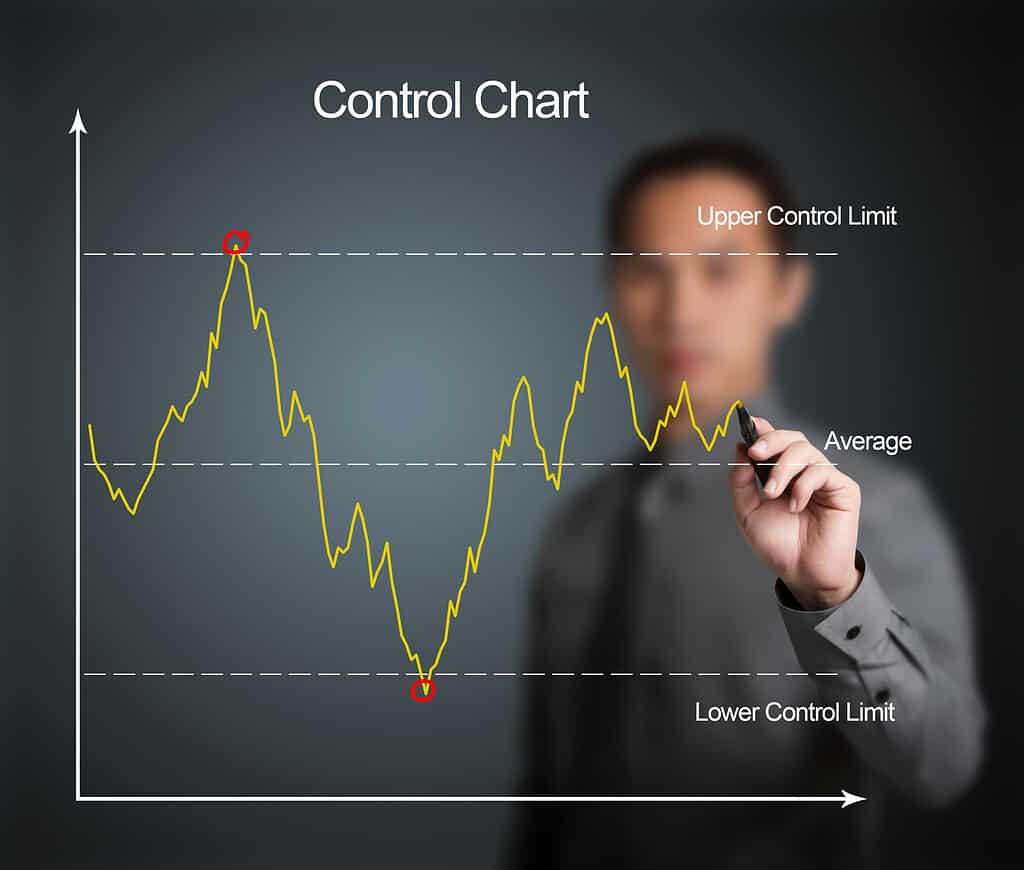

How to Set and Use Control Limits to Improve Your Process Performance

Published:This article will introduce you to control limits. You will learn about the role of control limits, how they were designed, and the role they play in process improvement.

Read more »

The Complete Guide to Understanding Control Charts: How They Work, and Which to Use

Published:Control charts have two general uses in an improvement project. Undeniably, the most common application is as a tool to monitor process stability and control. A less common, although some might argue more powerful, use of control charts is as an analysis tool. Throughout this guide, you’ll have the various control charts identified. Accordingly, you’ll […]

Read more »

Variable vs. Attribute Data: What’s the Difference?

Updated:Throughout any project, you’re going to gather up quite a bit of data. Now, this can be broken down into two categories: variable and attribute data. Understanding the difference and learning how it is applicable during the analysis stage can be crucial for future decision-making. So, with that in mind, let’s take a deeper dive […]

Read more »

Trend Charts in Quality Management: Enhancing Process Monitoring

Published:You can learn a lot about your process by monitoring its change over time. There are different trend charts which will allow you to do that. Let’s look at a few.

Read more »

Assessing Process Stability: Techniques and Tools

Published:Have you ever wondered why your doctor may keep you waiting in the waiting room or why you have to fast before doing a blood test? Let’s see if Lean Six Sigma can give you an answer.

Read more »

Steps in Constructing an X-Bar and R-Control Chart

Published:Steps in Constructing an X-Bar and R Control Chart: This document contains the step-by-step instructions to construct an X-bar and R control chart. First the R chart is constructed. If the R chart validates that the process variation is in statistical control, the XBAR chart is constructed.

Read more »

Tolerance Range: Expecting Variation in Your Data

Published:Understanding and determining the upper and lower statistical limits are the key to determining tolerance range (TR). Find out more about this LSS concept.

Read more »

Monitoring Process Performance with X-Bar and R Charts

Published:Is the variation in your process data to be expected, or has something special occurred? A control chart will give you the answer. The X-bar and R chart will give you the details.

Read more »

I-MR Chart: Understanding Your Process Stability

Published:The Individuals-Moving Range (I-MR) Chart is one of the most widely-used control charts in statistics and the standard for most situations where data was collected in individual data points. It allows such a process to be assessed for stability both in terms of central tendency as well as variation.

Read more »

Warning Limits: Catch Outliers in Your Production

Published:Lean business operations don’t happen without defining expectations, collecting data and monitoring results. Statistical limits serve your streamlining goals through efficiency quality control and loss prevention.

Read more »

Natural Tolerances: Expecting the Drift

Updated:The economical method of setting the control limits of a process to a specific level is known as natural tolerance. Natural tolerances work well for typical desired levels of control and are useful for reviewing the practicality of the specification limits.

Read more »

The Role of Lower Control Limit in Process Stability and Improvement

Published:Process stability is a critical need before trying to improve that process, and control charts are used to assess it. The lower control limit is one of the three fundamental lines on a control chart for identifying a lack of stability.

Read more »

Steps in Constructing a p-Chart: Finding Nonconformance in Your Data

Published:Steps in Constructing a p-Chart: p Charts can be used when the subgroups are not of equal size. This guide shows you the steps involved in constructing a p Chart.

Read more »

Short-Run Statistical Process Control Techniques

Updated:Short production runs are a necessity in high-mix, low-volume manufacturing environments. The trend in manufacturing has been toward smaller production runs, with production runs – as well as products – tailored to the individual customer’s needs. Although this minimizes inventory and improves responsiveness to the customer, it complicates the application of statistical process control (SPC). Classical […]

Read more »