Latest from iSixSigma

Fishbone Diagrams: How to Diagnose Process Problems

Key Points Fishbone diagrams are instrumental in problem-solving. Fishbone diagrams aren't detailed by design but

Continue reading

Combining the Harada Method with Other Techniques (Kaizen, Lean, SMART, etc.)

Key Points Structured Goal Achievement: The Harada Method’s ambitious goal setting can be enhanced by

Continue reading

How Takashi Harada Created The Harada Method To Elevate Athletes, and Business

Key Points From Coaching to a Universal Success Framework: Takashi Harada, originally a track and

Continue reading

Real-Life SIPOC Examples in Manufacturing

Key Points SIPOC diagrams can be used in any industry. They excel in manufacturing, especially

Continue reading

Is SIPOC Still Relevant? 9 Alternatives

Key Points SIPOC diagrams are high-level overviews of the various components of a process. There

Continue reading

How AI Can Be Used in the DMAIC Process

Key Points Enhanced Data Collection and Analysis - AI improves data collection in the Measure

Continue reading

Productivity Target: Reaching Your Goals

Key Points Productivity targets are a set of expected outputs from a given input. Expectations

Continue reading

What AI Tools Can be Used in Lean Six Sigma Projects?

Key Points Natural Language Processing (NLP) is used to analyze customer feedback, identify key issues,

Continue reading

Design of Experiments: A Primer

Key Points A DOE is a great way of analyzing the relationship between factors. You

Continue reading

Finding the Sigma Level of Customer Complaints

Key Points You can determine the Sigma level of your production by looking at the

Continue reading

Quality Program Report (QPR): Guaranteeing You Hit the Mark

Key Points A QPR is a report created to show whether or not a product

Continue reading

The Cause-and-Effect (a.k.a. Fishbone) Diagram

Key Points Fishbone diagrams are an effective way to brainstorm root causes for a potential

Continue readingLean Six Sigma Case Studies

Case Study: Using Six Sigma in a Non-Six Sigma Culture

Anyone who has worked in manufacturing has probably experienced some level of finger-pointing when shipments

Continue reading

U.S.A.F. Uses Continuous Process Improvement on the B-2 Bomber: Part 2

In this case study, the 509th Maintenance Group of the U.S. Air Force used an

Continue reading

U.S.A.F. Uses Continuous Process Improvement on the B-2 Bomber: Part 1

In this case study, the 509th Maintenance Group of the U.S. Air Force used an

Continue reading

Project Examples from an LSS Deployment for Cultural Transformation

My company benchmarked against other manufacturing businesses before starting its cultural transformation change. They formed

Continue reading

Case Study: Increase Revenue by Decreasing Prices

A division of a diversified organization develops and manufactures samples of new drugs for clinical

Continue reading

The Cost of Customer Misalignment (& How to Fix It)

This consumer products company has a large portfolio of products. Working with key customers, the

Continue readingGet Lean Six Sigma Certified

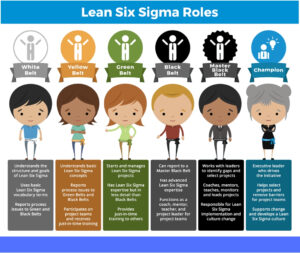

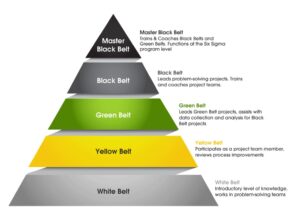

Black Belt vs. Master Black Belt in Six Sigma: What’s the Difference?

What is a Black Belt (BB)? A Six Sigma Black Belt (BB) is a trained

Continue reading

Lean Six Sigma Certification Levels

Dr. Mikel Harry is often credited with adapting the martial art concept of belt rankings

Continue reading

Lean Six Sigma Champion Training and Certification

The rock band, Queen, celebrated Champions with these lyrics; “We are the champions…. my friends….And

Continue reading

Lean Six Sigma Master Black Belt training and certification

Does the term Master Black Belt sound pretty impressive? It should, because it is the

Continue reading

Lean Six Sigma Black Belt Training and Certification

Will having a Lean Six Sigma Black Belt allow you to break bricks and beat

Continue reading

Lean Six Sigma Green Belt Training and Certification

Lean Six Sigma Green Belt is where your more advanced training and certification begins. If

Continue reading

Lean Six Sigma White Belt Training and Certification

You are ready to start your Lean Six Sigma journey but where do you start?

Continue reading

Lean Six Sigma Training and Certification

Organizations have been deploying and implementing Lean Six Sigma for decades. Yet, there are still

Continue reading

Lean Six Sigma Yellow Belt training and certification

After completing your training and certification for White Belt, your next step might be to

Continue readingLatest Concept Articles

Productivity Target: Reaching Your Goals

Key Points Productivity targets are a set of expected outputs from a given input. Expectations

Continue reading

Quality Program Report (QPR): Guaranteeing You Hit the Mark

Key Points A QPR is a report created to show whether or not a product

Continue reading

The Hidden Factory: Understanding the Unseen

Key Points The Hidden Factory is a concept that arises from workarounds for defects in

Continue reading