Most CEOs of small and mid-sized businesses are aware of Six Sigma and what it has done for other companies. But some think the quality improvement program only works in larger companies. Of course, that is not true. Six Sigma can help grow any company by giving it the all-important competitive edge. For the majority of small business CEOs, the only thing that holds them back from seriously exploring Six Sigma is not knowing how to get started.

What CEOs Should Expect of Six Sigma

The need to implement a quality improvement program like Six Sigma becomes painfully clear when a business fails to meet customer needs, and, as a result, begins to lose customers, market share and money. In that situation, a continuous improvement program literally becomes a means to survival. But CEOs should also know that a quality improvement program such as Six Sigma can improve any business – even a successful one. Proactively implementing a quality improvement initiative can help ensure that a business that is successful today stays that way in an increasingly competitive and demanding global marketplace.

Six Sigma is basically a common sense approach to solving problems within a disciplined and structured methodology. Most people would agree that it is only common sense to understand a problem before trying to resolve it. The Six Sigma approach includes understanding the problem, collecting and analyzing the data, identifying the root cause, implementing the corrective action/solution, and making sure that the process cannot revert back to its old ways. It is a data-driven methodology, meaning that decisions are based on facts and data, not gut feelings or how it is done somewhere else.

Since most functions in business, or in life for that matter, can be seen as processes, Six Sigma aims to understand, analyze and improve processes via projects. The projects take on one process at a time with the goal of improving the results of the process.

As people become familiar with the basic methodology, they wonder why anyone would not use it. Why spend time and money implementing a solution to a problem without understanding what caused the problem in the first place? How can anyone be sure that the problem will not reoccur, even after implementing a solution, if they are not exactly sure what caused the problem to begin with? How many solutions have to be implemented (and how much time and money spent) to solve the same problem over and over before the “right” solution, the one that addresses the root cause, is implemented?

What Six Sigma Will Do for the Business

Using the Six Sigma approach will enable any business to improve customer satisfaction, product and service quality and on-time delivery, and shorten development time. It provides the tools to identify and reduce or eliminate defects, non-conformances and disconnects; to streamline and optimize processes resulting in reductions in cycle time, work in process, inventory turns and costs; and to improve productivity and efficiencies. It can be used to drive improvement in manufacturing, engineering, service, transactional and any other environment.

Because Six Sigma empowers employees by involving them in process improvement, morale and satisfaction increase. The methodology mandates that successes are recognized throughout the business, generating enthusiasm and excitement and more successes. As employees experience these successes, they bring a fresh approach to their work. All this adds up to providing more value to the customer and the business.

In addition to driving improvements in customer satisfaction, quality, cycle time and cost, the key to improving the long-term health of a business is to increase the value of its products and services in the marketplace. Six Sigma’s “voice of the customer” focus and associated tools enable the business to identify what the customer values and then translate those things into defined requirements. The business can use those requirements to increase the value of its products and services, which then positions the business for continued success.

What Does the CEO Do to Get Started?

Once the decision has been made to implement a Six Sigma quality improvement strategy, a CEO should determine how authority and control (governance) of the Six Sigma program will be addressed. Does the CEO have the time to be responsible for the strategic, tactical and management decisions required for the Six Sigma improvement program? If not, there may be a need for a governance body, such as a group of company executives. The CEO/governance body should establish the ground rules for how the Six Sigma program will operate. In any case, the CEO must be totally committed to the idea of Six Sigma. Anything less and the program is unlikely to succeed.

Some of the many things that must be considered when developing a Six Sigma deployment plan include:

- Number of Champions to be trained, when and by whom.

- Method and criteria for selecting and assigning Champions.

- Number of Black Belt candidates to be trained, certified, by whom and when.

- Selection criteria for identifying Black Belt candidates.

- Assigned or voluntary Black Belts.

- Part-time or full-time Black Belts.

- Number of projects Black Belt trainees will work on at a time (typically one).

- Permanent Black Belts or rotation back into the business role they came from.

- Number of projects a Black Belt works on during a 12-month period.

- Method for identifying, prioritizing, selecting, assigning, tracking, monitoring and reporting Six Sigma projects.

- When or if the business needs a Master Black Belt.

- Content for project scorecards/dashboards.

- Frequency of executive reviews.

- Ownership of each project outcome.

- Finance department’s role in verifying project costs and savings.

- Process for recognizing, rewarding and celebrating project successes.

The person who will be responsible for developing the deployment plan and building the infrastructure to support it must be identified. This person may work alone or enlist a small team of people to help investigate Six Sigma programs, consulting services and other sources for Six Sigma training, and to select the appropriate Six Sigma program for the business. Unless the business has the resources available to hire an experienced Six Sigma Master Black Belt (mentor for team leaders) with both training experience and successful project work, it is more reasonable for the business to purchase outside consulting services to provide the initial Six Sigma training.

Communication plans should be developed and deployed so that all employees are aware of the quality improvement effort and understand why it is being implemented and institutionalized.

Training plans should be written to include such details as classes, schedules, participants, costs, the tools to be taught and whatever else will be needed. Training should be outlined for Champions (project sponsors), as well as Black Belts (project leaders) and others who will be Six Sigma practitioners. Also documented should be the methods that will be used to disseminate Six Sigma thinking throughout the business.

It is extremely valuable for the CEO and other business leaders to attend Six Sigma Champion training. Champion training is usually a one-day event and covers the high-level technical aspects of Six Sigma – how to lead a Six Sigma initiative and the Champion’s role in ensuring availability of resources, removal of roadblocks, resolution of issues slowing progress, etc. It strengthens the top-down approach needed to deploy Six Sigma and gets company leaders on the same page regarding the program.

Candidates for Six Sigma Black Belt training need to be identified, trained and certified. Many of the organizations and consulting companies that provide Black Belt training also provide certification, which is known as independent third-party certification. The Black Belt candidates, usually among the company’s best and brightest, train on projects that address real business needs and that can be accomplished in a relatively short period of time (three to six months). The projects done in training demonstrate capability and earn the Black Belts certification. Successful completion of each project can be shared with others in the business to get buy-in and generate enthusiasm for the program.

Six Sigma Black Belt training varies but typically includes at least four weeks, 160 hours, of classroom work spaced over several months so that concepts and tools can be applied to a real-world project between training sessions. Most programs cover each of the DMAIC phases (Define, Measure, Analyze, Improve, Control). Black Belt certification criteria again varies but typically consist of attending and participating in class, passing a certification exam and successfully completing one or more Six Sigma projects.

Once the Program’s Core Is Formed

Once the business has a team of several trained and certified Six Sigma Black Belts with successful project experience, there is the possibility that one or more of them may have the skills, interest and enthusiasm needed to provide training for additional candidates internally. Another way to implement training internally as well as help lead the program is to hire a Master Black Belt from outside the organization as a full-time employee. Master Black Belts have completed a significant number of successful Six Sigma projects and are trained to guide and mentor others in Six Sigma tools and methodologies.

In identifying what Six Sigma projects to undertake first, the business should focus on those aspects of the business that are not performing to the expected or desired levels. The goal should be to minimize processes that do not add value to the products and services, and to improve those processes that do. To know where performance is lacking and needs improvement, performance data (measurements) must be available and, if not available, measurement data must be collected before work can begin. And performance measures are essential at the end of every Six Sigma project to prove that performance improved. A CEO and the management team have a general idea of what should be targeted for improvement first, but in the data-driven methodology of Six Sigma, performance metrics are the final word.

Typically, early projects focus on improving those aspects of the business that affect cost, quality, cycle time or customer satisfaction. When choices have to be made, it is always appropriate to start with areas that are causing customer dissatisfaction, since the customer is the source of revenue.

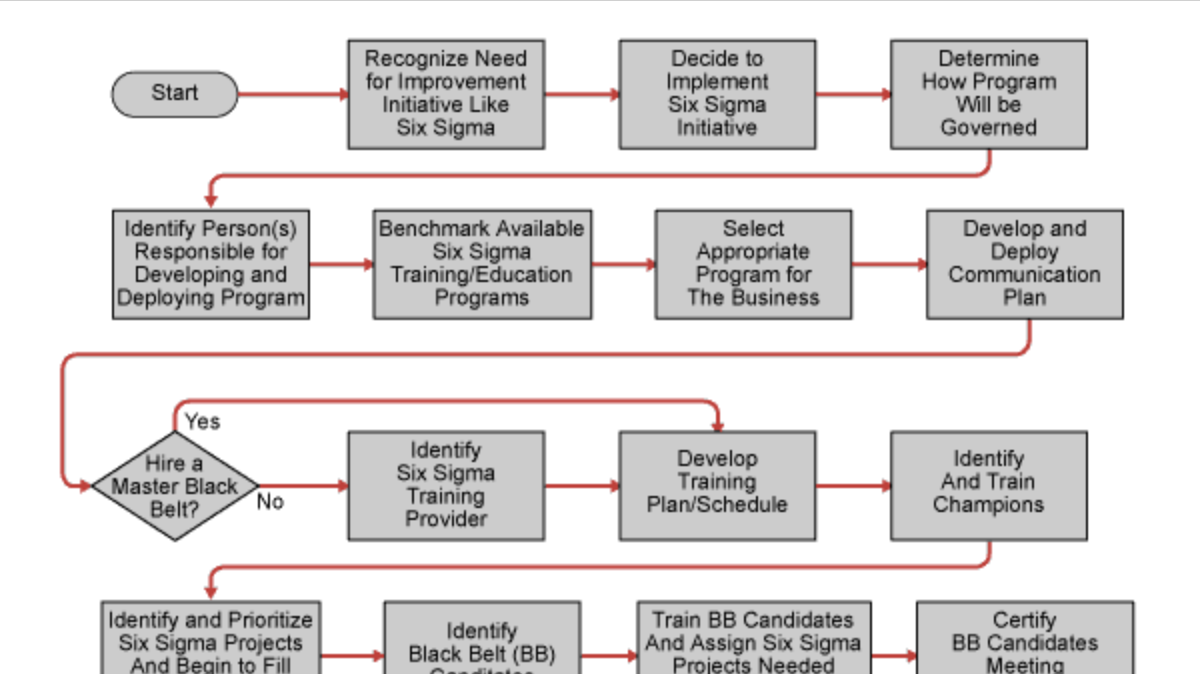

The figure below illustrates a process flow for deploying a Six Sigma quality improvement initiative.

What Does the CEO Do Next?

To be successful, Six Sigma needs more from the CEO than a go/no-go decision and the delegation of program responsibilities to company executives. Six Sigma works best with a top-down approach – when the CEO and senior leaders own it, support it and drive it. What comes after the initial deployment depends on how far into the business, how ingrained into the everyday thinking and approach, the CEO wants to drive it.

Some businesses may be content with having a small core group of Black Belts who work on difficult problems. Some may want the Six Sigma concepts and tools permeated throughout the business and so ingrained in the thinking that there is no other way to do business. Others may be somewhere in between. Each business, regardless of its size, has to learn what works and what does not in its particular culture.

Whatever the degree of implementation, all will benefit from embracing Six Sigma philosophies, concepts, tools and methodologies. There are no losers when a business refines and optimizes a continuous improvement program while constantly focusing on the customer and the drive to increase the value of it products and services.

That is what Six Sigma does for a business – no matter what its size.