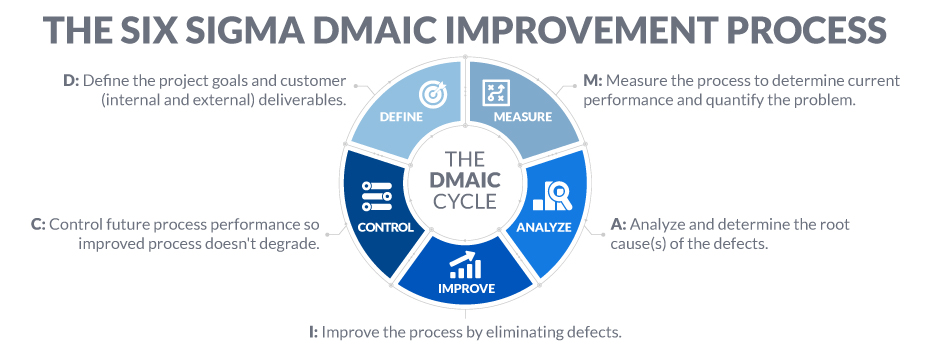

DMAIC is an acronym for Define, Measure, Analyze, Improve, Control. It is a process improvement methodology of Six Sigma that’s used for improving existing processes. See DMAIC Methodology.

DMAIC is pronounced: Duh-May-Ick.

What Is DMAIC?

DMAIC refers to a data-driven quality strategy for improving processes and is an integral part of the company’s Six Sigma Quality Initiative. It is an acronym for five interconnected phases: Define, Measure, Analyze, Improve, and Control.

DMAIC Process Steps

Each step in the cyclical DMAIC Process is necessary to ensure the best possible results. The process steps:

Define the Customer, their Critical to Quality (CTQ) Issues, and the Core Business Process Involved

- Identify who customers are, what their requirements are for products and services, and what their expectations are

- Define project boundaries the stop and start of the process

- Define the process you want to improve by mapping the process flow

Measure the Performance of the Core Business Process Involved

- Develop a data collection plan for the process

- Collect data from many sources to determine types of defects and metrics

- Compare customer survey results to determine the shortfall

Analyze the Data Collected and Process Map to Determine the Root Causes of Defects and Opportunities for Improvement

- Identify gaps between current performance and goal performance

- Prioritize opportunities to improve

- Identify sources of variation

Improve the Target Process by Designing Creative Solutions to Fix and Prevent Problems

- Create innovative solutions using technology and discipline

- Develop and deploy an implementation plan

Control the Improvements to Keep the Process on the New Course

- Prevent reverting to the “old way”

- Require the development, documentation, and implementation of an ongoing monitoring plan

- Institutionalize the improvements through the modification of systems and structures (staffing, training, incentives)

Real-world Uses

We’ve talked about the whats when discussing this methodology. However, one thing we’ve neglected at length is how it functions in the real world. So, let’s look at one scenario using these principles. Imagine you’re looking to get your kids to clean your room.

First, you’d define the scope of the project, i.e. their room. Next, you’d need to measure the space or dictate how clean you want it. Of course, you have to analyze available storage solutions. An improvement would come about from using tools to get the cleaning going. Finally, we’re at control where you take inventory of where things are stored.

No clue if children are receptive to Lean Six Sigma methodology, but think about how clean your house would be if they were.

Concepts and Tools for Process Improvement

So, you’re up to speed on how this approach works, but you’re hungry for more? Well, you might want to look at how Dr. Pepper’s use of DMAIC and Lean Six Sigma has transformed its fortunes. Our post-mortem provides a great look at how these principles have led to millions of dollars of profit for the company since its implementation.

Further, understanding the role of the Sigma Level shifting in a process is key. As such, you’ll want to brush up on how these shifts affect your processes to make suitable improvements or stay the course.

Summary

Implementing DMAIC during your improvement process can yield impressive results. While it might seem daunting at first glance, the proof is in the pudding. Organizations utilizing Six Sigma across the world have made great use of this process. You owe it to yourself to reap the benefits of this effective means of creating meaningful improvements in your process.

Excerpted From GE’s DMAIC Approach