You are probably familiar with the notion that there are costs of poor quality, often shown as COPQ. These represent both internal and external failures to maintain good quality. There are also costs associated with maintaining good quality sometimes represented as COGQ. These costs represent appraisal and prevention costs. Total Cost of Quality (TCOQ) is the sum of COPQ and COGQ.

Overview: What is TCOQ?

The graphic below illustrates the components of TCOQ.

Components of Total Cost of Quality

Here is more detail on each:

- Prevention Cost – costs associated with activities specifically designed to prevent poor quality in products.

- Appraisal Cost – costs associated with activities specifically designed to measure, inspect, evaluate, or audit products to assure conformance to quality requirements.

- Internal Failure Cost – costs incurred when a product fails to conform to a quality specification before shipment to a customer.

- External Failure Cost – costs incurred when a product fails to conform to a quality specification after shipment to a customer.

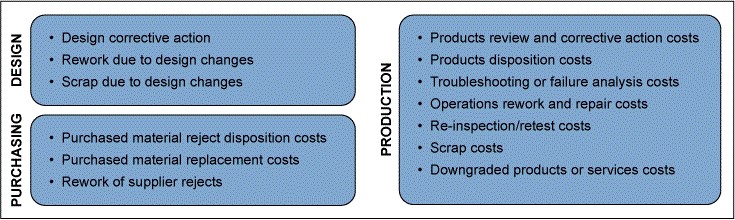

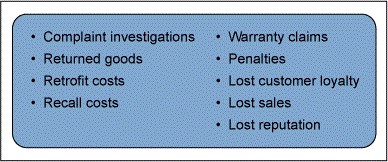

Here are some examples of internal and external failures:

Examples of Internal Failure Costs

Examples of External Failure Costs

An industry example of TCOQ

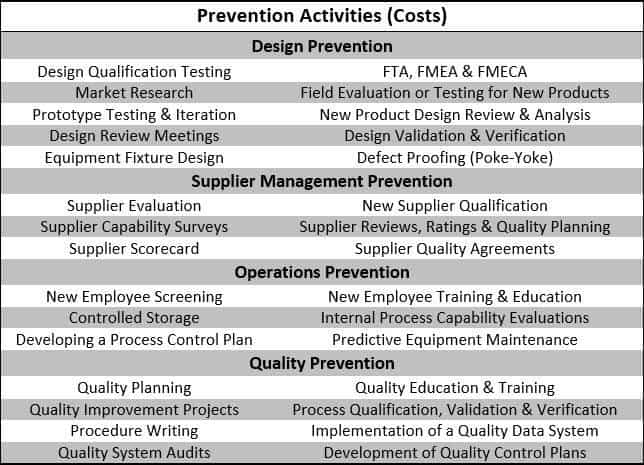

The company’s Vice President of Quality wanted to capture the costs associated with prevention as part of his analysis of the TCOQ. He used the following checklist to start collecting actual costs:

Frequently Asked Questions (FAQ) about TCOQ

What are the elements of Total Cost of Quality?

The two elements are costs associated with internal and external failures, and the costs associated with maintaining good quality. These are often referred to as Cost of Poor Quality (COPQ) and Cost of Good Quality (COGQ).

What are some potential internal failures associated with COPQ?

Rework, scrap, excess downtime, reduced production time and repair.

What are some possible external failures that impact the TCOQ?

Returned goods, recall costs, warranty claims, lost sales, negative impact on reputation and customer loyalty.