The customer just placed a new order requesting 100 widgets by the end of the week. If we keep producing at our current rate, will our cycle time be able to provide the parts in time? What is the rate we must produce the widgets to meet their deadline? Well, that rate has a name, and it is takt time. We use this time to compare it to the system cycle time to determine whether we have the ability to meet customer demand.

An overview: What is takt time?

Takt time is the amount of time an item or service needs to be completed if a customer’s on-time delivery deadline will be met. The amount of time between one part being completed and the next part being completed must be the same or less than the takt time, or we can assume that the parts will not be produced per the customer’s schedule.

The actual word was borrowed from the German language, and loosely translated, it means “beat,” like a music beat or rhythm.

RELATED: LEAD TIME VS. TAKT TIME

A closer look at takt time

The calculation for takt time is simple: Take the available amount of time being used to produce the item and divide it by the product demand.

Takt Time = Customer Demand / Available Time

For example, an order for 80 bicycles has been placed at the beginning of the week and is due for the customer to pick up at the end of the week. For this case, we will assume that the manufacturing facility runs a single shift, lasting eight hours. So, the available time is 40 hours, and the demand is 80 units. Using the formula, we take 80 and divide it by 40, and get a Takt Time of two units per hour, or one bicycle per half hour. This means that one bicycle must be completed and ready for the customer every 30 minutes. If the bicycles are completed any slower than every 30 minutes, the customer order will not be complete by the end of the week, and you will have a disappointed customer on your hands.

This is where cycle time enters the equation, cycle time being how long it takes for a product to be produced. It is important to know the cycle times of your processes, and compare them with the takt time, to verify that cycle time is always less than takt time. Both values are variable over time, though cycle time should shift more slowly, and takt time can change any time the customer decides to increase or decrease an order size.

Using the previous example, if it takes the facility 50 minutes to produce one bicycle, and the takt time is 30 minutes per unit, the facility will not be able to meet the on-time delivery demands of the customer.

What can the company do about this problem? There are multiple options.

- Solution 1: First, they could consider running two shifts. This would change the takt time formula for available time from 40 minutes to 80 minutes, changing the takt time from 30 minutes/unit to 60 minutes/unit. This would allow takt time to be met.

- Solution 2: The facility can run two production lines instead of one, allowing for two bicycles to be produced every 60 minutes, changing the cycle time to 30 minutes a unit, and decreasing the cycle time to a value less than the takt time.

- Solution 3: Managers could examine the existing production line and look to remove inefficiencies that slow production. It is possible that part shortages, defects, overprocessing and other wastes are complicating the process, lengthening the total cycle time. By removing these wastes, the cycle time may decrease under 30 minutes, lower than the takt time requirements.

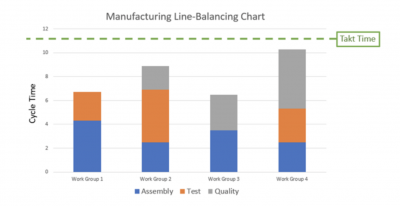

Takt time is key when looking at how to properly balance a production line. When setting up a production line with multiple steps, it is best to level-load the line so that each step in the process takes approximately the same amount of time, and that all steps take less time than the takt time. The step that takes the longest amount of time, known as the bottleneck, must be lower than the takt time or customer demand cannot be met.

3 takt time best practices

1. Remember not to confuse takt time with cycle time

Many professionals make this mistake. Companies have been known to state that their processes have a takt time value; they do not. Takt time is a function of customer demand and available time, and for many products, takt time is in constant flux as customer demand changes. A change to the system will not impact takt time, but it will impact cycle time. Note that if you duplicate and run additional production lines or increase the hours available for use on a production line, takt time changes.

2. Remember that since takt time is a function of customer demand, whenever you have large changes in demand from the customer, you’ll need to review the process and verify that the cycle time can meet the new demand levels.

3. If a production line for one product is also used for other products during the time period in question, remember to not count the time that the production line is producing other products

Availability of the production line will impact the true available time value for the takt time calculation. Also, availability can be impacted by machine breakdown, personnel availability, etc. If the process lacks the ability to produce at times, due to sharing tools or personnel with other product or service efforts, then those times should not be considered as available time in the calculation.

RELATED: TAKT TIME VS. CYCLE TIME

Frequently Asked Questions (FAQ) about takt time

My takt time and cycle time are the same, so things are good to go, correct?

Not really. The problem with this assumption is that things must go perfect, which simply does not happen in the real world. It is recommended that your takt time be between 5% and 17% larger than your cycle time.

There are many reasons for this. For example, are their personnel breaks inside your available time? Does your company occasionally have all employee meetings, or supervisor stand up meetings that occur during the traditional available time? Do personnel occasionally have personal issues that keep them from working at 100% peak efficiency? Is one of the machines having temporary issues causing a slight slowdown, or is possibly off-line for a couple of hours for maintenance? Does the time account for the occasional rework issue?

Give yourself some room for everyday process time-consuming problems, and aim for your cycle time to be slightly lower than your takt time.

My process produces in batches, so is the takt time the amount of time between batches?

When working in batches, you will need to take the time between batches and divide it by the quantity in the batch to obtain the takt time, since takt time is the time between individual pieces.

My customer wants a lot, and they want it now. How do I calculate takt time when the customer wants it yesterday?

The customer may want it all now, but there is an absolute time where they will become irritated, become negative regarding the relationship, and eventually they will look for a new supplier. Even in today’s fast-paced world, instantaneous is rarely an option for some types of orders. You must use your judgement as well as social cues from your relationship with your customer to properly determine the true delivery date expectations when not provided an exact date from the customer.

Is takt time what I want to use to measure for office environments?

While the use of takt time is far more prevalent in manufacturing and construction, takt time is just as valuable a tool to utilize in the office environment. The key issue with using takt time in an office environment is just how much time is being used for each task, document, or service, sometimes making it difficult to know the true available time value to use in the takt time formula.

Takt time represents the maximum cycle time we can maintain and still meet customer demand

Takt time is a quick calculation that allows you to verify that your processes can keep up with customer demand. It can be a tricky value to maintain, as it is always in flux whenever the customer changes the demand level. When you know the takt time, you are always in tune with customer on-time requirements, and less likely to miss a deadline due to ignorance of your own capabilities. Know your customer, know your process, and know whether the processes as they currently stand can continue to meet your customer’s demand.