© Ground Picture/Shutterstock.com

Key Points

- A SOS allows you to define the specific steps of a process.

- It allows your employees to stay on track, keeping everyone on the same page.

- It is a crucial document to create with any sort of process.

While a standard operating sheet may at first appear to be a simple piece of paper, it has the potential to unlock so much more for your organization.

Overview: What Is a Standard Operating Sheet?

A standard operating sheet (SOS) is a document that outlines all elements of a specific operation. This includes each step involved in the particular process as well as the approximate amount of time taken. If an operator is working with a machine, these times can be further divided into Manual or Robot time estimates.

3 Benefits of Standard Operating Sheets

Okay, it’s a piece of paper…so what? Glad you asked! This isn’t just any piece of paper, it’s a piece of paper with benefits that will help improve your organization’s output.

Standardization

As the name suggests, one benefit of a standard operating sheet is that it brings standardization to a process. While traditionally used in Lean manufacturing, standard operating sheets can be used anywhere there exists a process that needs to be followed the same way each time for best results (ex., changing the toner on the office printer).

By having the process steps and time estimates posted at their point of use, any operator can see how long a job will take and perform the process in a repeatable way. This reduces variation in the process and helps minimize error.

Visualization

Standard operating sheets typically contain a diagram of the workstation where they are posted. This helps show how the specific operation needs to be performed and can draw attention to areas where extra care must be taken to avoid injury or mistakes. With a glance, it is easy for someone to gain an understanding of the work to be done, regardless of their level of experience with the equipment.

Employee Engagement

A standard operating sheet documents all of the elements of a given operation based on the best way we know how to perform them right now. This is a great starting point for training employees on how to properly conduct the process, then they can refer to the more detailed standard work with any questions they may have.

As employees perform a given operation, they may find new ways to make the job simpler, easier, or faster. Having the standard operating sheet posted as a visual baseline allows operators to then have conversations with their team lead or shift manager about ways that the process can be improved.

Why Do You Need One?

Think about baking a cake for a moment. You wouldn’t go about creating something from scratch without a plan in place, right? While you might know the basics of what goes into baking a cake, having a recipe on hand makes the whole process far simpler.

As such, you can see the power of this document. It gives your employees explicit instructions, allowing them to work to the standards your organization has set. It still allows for creativity and thinking outside the box. However, having a game plan in place for tasks is a recipe for success.

How to Create a Standard Operating Sheet

©Oakland Images/Shutterstock.com

Now that we’ve seen the benefits standard operating sheets can provide, let’s look at what it takes to write one.

Select the Operation

To determine whether an operation would benefit from a standard operating sheet, consider criteria such as difficulty of the process, inconsistencies seen in time or quality, and accident rates.

Analyze the Operation

It’s helpful to observe the process in action to record the current situation. Additional information about the operation can be gathered from historical data, employee interviews, and process flowcharts.

Develop the Best Method

Before creating a standard operating sheet, be sure to develop the best method for conducting the operation. Question what is currently being done and if there are ways to reduce waste. Test out the method to make sure operators can perform the tasks safely and effectively.

Create the Document

Outline the main steps and the tasks associated with each one. Include the amount of time each task takes and any key points to remember around safety or quality. Include images of the work area and process steps as well.

An Industry Example

Imagine this: You walk into an automotive manufacturing plant. There are cars everywhere in various states of assembly and separate lines dedicated to a different phase of production.

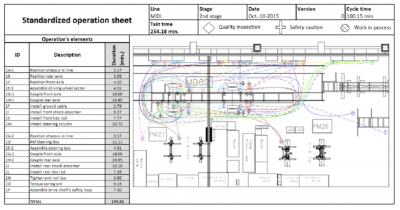

Amid this chaos, you wonder how any of the employees on the floor can keep track of what goes where. Good thing each area has a handy-dandy standard operating sheet, like this one:

Image source: www.researchgate.net.

Looking at this standard operating sheet, it is clear exactly what steps need to be taken to configure the base of the automobile as well as how long each part of the operation takes.

Having this standard in place not only allows operators to make sure they are performing the steps correctly, it also allows them to check their work quality to make sure it meets the requirements.

Best Practices

As standard operating sheets can be such a powerful resource, there are some things to keep in mind when it comes to using them in your organization.

Keep It Simple

Since a standard operating sheet is, in fact, a sheet of paper, it is important to simplify how the process information is presented so that the operation can be easily understood. If there is too much text, it is easy for the message of how to operate to get lost. Include pictures wherever possible to help simplify the steps and show (rather than tell) how they need to be completed.

Go to Gemba

When creating a standard operating sheet, it is important to outline the work as it happens. The only way to ensure that the standard operating sheet will reflect the appropriate steps and time estimates is by observing the operation and workstation setup. To do this, go to Gemba — the place where work activities are performed.

Update Periodically

Since there is a time element associated with standard operating sheets, it is important to periodically review them to make sure the time approximations are still applicable. If employees engage in continuous improvement and change how an operation is performed, the steps and times outlined on the standard operating sheet will likely change as well.

Other Useful Tools and Concepts

Looking for more tools and concepts to transform your organization? Why not consider the Paynter Chart? This handy chart allows you to quickly grasp data when looking at KPIs and problems alike. Further, it provides a comprehensive view so that everyone can stay on the same page.

Additionally, you might want to look into how a process sign-off works. While we spend a fair amount of time analyzing the minutia of processes here, the final step in a project is always one of the most vital. Learn about how this final step can act as a vanguard for your organization in our guide.

Conclusion

If nothing else, remember this: Standard operating sheets outline all elements of a specific operation. By understanding the process steps and the amount of time they take, operators can ensure they are performing a given task the right way and help train others to ensure consistent results.

The image featured at the top of this post is ©Ground Picture/Shutterstock.com.