© Cast Of Thousands/Shutterstock.com

When things go wrong, it’s tempting to stick another Band-Aid on and get your products or processes rolling again. Hey, wait a minute! If we get to understand what is really causing failure and fix it surely this is a winner? Welcome to root cause and failure analysis, a proven way to quality improvement.

What Is RCFA?

Root cause and failure analysis (RCFA) is the process of investigating the root cause of a failure in a product, process, or service and using the information to develop and implement a change to prevent the recurrence of the failure.

Before undertaking RCFA, it’s important to understand the differences between symptoms and causes, as the goal is to understand and address the true root cause of failure and not treat the symptoms of failure. Let’s clarify these two terms:

- Symptom: a consequence, output, or indication of a problem or failure

- Root cause: the primary reason a problem or failure has occurred

Methods and Approaches

There are many well-proven methods and tools we can use during RCFA that help us drill down to the root cause of the failure or non-conformance. Some examples include:

- 5 Whys: An iterative process that interrogates the failure by asking “why?” several times (typically 5), driving the search to find the root cause.

- Fault Tree Analysis (FTA): A top-down deductive process that uses logical reasoning to explore the causes of failure.

- Cause and effect (fishbone) diagrams: A visual representation that maps and collates the various potential causes of the effect.

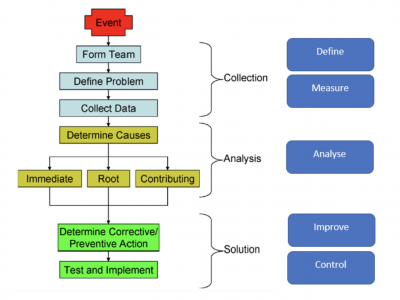

The RCFA process can be subdivided broadly into three phases, and there is some synergy with a classic Six Sigma DMAIC methodology. The three phases are:

- Collection: Here we form a team to investigate the failure, define the problem, and collect data from the incident. When defining the problem, it is important to keep it short and simple to understand.

- Analysis: Here we apply our tools and methodologies to reveal the failure cause and effect chain that ultimately leads to the root cause of failure.

- Solution: Here we generate and implement corrective actions to be applied to the root cause to remove or prevent recurrence of the failure.

Visually, the RCFA process is shown below, clearly showing the synergy to a DMAIC approach.

A PRACTICAL GUIDELINE FOR A SUCCESSFUL ROOT CAUSE FAILURE ANALYSIS

Symptoms and Root Causes

It is important before going into RCFA on your own, it is important to distinguish between symptoms and root causes. A symptom is a side effect of a problem, showing that there is an issue at hand. A root cause is the underlying reason for any defects, issues, or problems noted.

2 Benefits and 1 Drawback of RCFA

As with many process-driven activities, there can be benefits and drawbacks to be aware of when using RCFA. Let’s discuss some of these further.

It’s About Quality Improvement and Preventing Recurrence

Something has failed, and we need to investigate and understand why. RCFA uses a structured methodology and toolset to get to the true root cause of failure. If we understand and address the root cause, we have an improvement in quality, and crucially, we prevent the recurrence of the failure.

There Are Some Great Tools to Help You Along the Way

We can take advantage of many tried and tested tools and methods to determine the root cause of failure. Depending upon the type and complexity of the failure, we could utilize cause-and-effect diagrams, 5 Whys analysis, FMEAs, and more.

It Can Take Significant Time and Resources to Find the Root Cause

Failures in complex products or processes take time to investigate and analyze the real root cause. Don’t underestimate the time and resources required; a lack of dedicated resources in RCFA is often the main reason a root cause is either not found or not addressed correctly.

Why Is RCFA Important to Understand?

In using RCFA, we have a structured and logical approach utilizing well-proven tools to determine the true root cause of failure.

Reduce Your Rework and Scrap Rate

When something has failed in your product or process, the likely outcome is going to be a non-conformance leading to rework or scrap. By investigating, understanding, and addressing the root cause of failure, we minimize the probability of non-conformance.

Improve Your Financial Bottom Line

Every time we have to rework or scrap an item, and every time we have to stop the production line, we incur a cost that negatively hits our financial performance. Conducting RCFA correctly and diligently reduces the likelihood of a significant impact on our financial bottom line.

Rebuild Customer Confidence

Failures happen — and sometimes they happen when your product or service is with the customer. If we truly understand the root cause of the failure and apply and control the appropriate corrective measures, we can rebuild customer confidence.

An Industry Example

A Tier 1 fuel pump supplier to the automotive industry was asked to investigate a number of pump failures reported from customer vehicles in service. The failure was catastrophic in nature, leading to engine damage and vehicles off the road. The Tier 1 supplier was proficient in root cause and failure analysis and assigned a Six Sigma Master Black Belt to facilitate the investigation.

An experienced team was assembled covering product development and manufacturing. Several failed pumps were received back at the supplier for analysis, and vehicle owners and service staff were interviewed to understand more about the failures. The problem definition was agreed upon, and the process of establishing the root cause progressed. The team used a combination of techniques, including 5 Whys, a review of the design and process FMEAs, and Fault Tree Analysis, all leading to the hydraulic roller/shoe assembly being the area of interest.

Detailed analysis of the hydraulic roller/shoe assembly revealed a process inconsistency with the material hardness. Pump failures occurred when the material hardness fell below a specific value. Utilizing 5 Whys once more, the root cause was determined to be the amount of time the material was held at temperature for sufficient material hardening to occur.

Changes were made to the hardening process, FMEAs were updated, and the revised parts went into production. Analysis of vehicles in service after the production change confirmed no recurrence of the failure.

RCFA Best Practices

Before we embark on our RCFA journey, here are a few pointers to ensure maximum success.

Get the Team Together

Effective RCFA needs the right people with the right knowledge to get to the real root cause. Make sure the team members are trained in the analysis techniques you plan to use, and never try and go it alone.

Be Diligent With Data

Typically there will be data collection and analysis as part of the RCFA, and understanding the true cause-and-effect relationships can be complex. There is no room for bias or manipulation with data, so make sure the outcomes are data-driven and not based on personal opinions.

Remember Your Goal

Some RCFA investigations are long and complex to complete, which can put significant strain on resources and team morale. Remember, however tempting it may be to apply a short-term fix, the goal is to identify the true root cause and not treat the symptom.

Other Useful Tools and Concepts

So, we’ve explored RCFA at length, but what’s next? Do you know how to properly conduct a null hypothesis test? This is one of the most useful ways of testing the veracity of a given hypothesis.

Additionally, learning how to account for special cause variation can help you drill down to what matters in a process. Rather than focusing on the random and chaotic, you can adapt and keep track of the things in your control.

Conclusion

There is a lot of sense in the old saying “address the root cause, don’t treat the symptom.” With RCFA, we direct our valuable resources to investigate and understand the real reasons for failure, implement corrective actions, and deliver quality products and services.

The image featured at the top of this post is ©Cast Of Thousands/Shutterstock.com.