Dealing with risks associated with failure modes in projects and processes is part of normal business activity. However, when is a risk acceptable? By evaluating the impact and likelihood of the failure to occur, we can prioritize which risks to accept and which to address. For this, we use an RPN or a Risk Priority Number.

Overview: What is RPN?

Risk Priority Number (RPN) is an integral part of the creation of a Failure Mode and Effect Analysis (FMEA) document. However, it is also used widely wherever a risk management strategy is deployed.

RPN is a multiplication of several factors that aim to assess the risk of a failure mode escaping and potentially presenting to the customer as a defect. The factors used are:

- Severity (S) – the impact of the failure mode being present. It is ranked 1 to 10 with 10 being the highest severity. The highest rating is typically hazardous without warning, with the potential for significant harm

- Occurrence (O) – the probability of the failure mode being present. It is also ranked 1 to 10 with 10 being the highest occurrence and typically defined as almost inevitable

- Detection (D) – the ease or capability of failure mode detection and escape prevention. Again, it is ranked 1 to 10 with 10 being the highest uncertainty of detection

RPN is then calculated as the multiplication S x O x D. There are a couple of things to be aware of with RPN:

- The scale is not continuous due to the possible multiplication of numbers e.g 13 is not a possible RPN

- It is possible to have a high RPN with a low severity rating. This can lead to teams focusing on low customer-impact failure modes

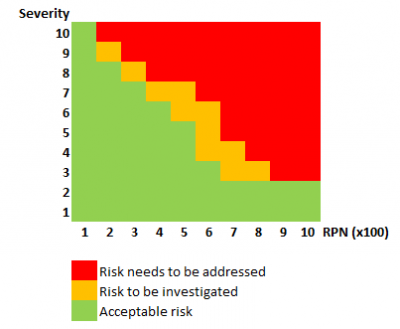

It is possible to use only the RPN value as a strategy to determine which failure modes to address first. For example, for all RPN values > 120. It is also common to use both the severity rating and the RPN value to prioritize risk reduction activities. This approach utilizes a risk priority matrix, an example of which is shown below for illustration only.

An Industry Example

A cosmetic company with an online shop for the purchase of their products wanted to improve their customer purchase experience. This was due to many poor ratings and negative feedback. Recognizing that changing the current online order and dispatch process would potentially introduce new risks and failure modes, their manager for Continuous Improvement (CI) assembled a team to review failure modes and develop a risk management strategy.

Being familiar with FMEA techniques the CI manager utilized the RPN methodology to drive the risk management strategy.

Following brainstorming sessions to document the new potential failure modes, the severity, occurrence, and detection of the modes were discussed and agreed upon. The RPN was then calculated. Afterward, the team then reviewed the numerical values for RPN and cross-referenced these to the severity rating.

The team devised a strategy to address all of the failure modes with a severity rating of 7 or higher in combination with an RPN of 150 or higher as a priority one. The team also agreed that any modes with a severity of 2 or less would be accepted and no action required.

Following a systematic review of RPN and severity, the risks associated with the new failure modes were addressed or mitigated. This led to an acceptable risk classification for all items and the successful deployment of the updated customer purchase experience.

Handy Tools for Problem-Solving

While we’ve discussed RPN at length, there are other factors to consider. RPN is only one aspect of defect and failure reduction. As such, you might want to take a closer look at FMEA as a whole, as this important document can lead to greater customer satisfaction down the line.

Additionally, I’d be kicking myself if I didn’t bring up Poka-Yoke, which addresses defects before they even happen. This handy concept can reduce the time needed to solve problems by addressing them before they even happen.

RPN in the News

Risk priority numbers have remained a steady element in FMEA, but there are some who theorize that we can shift away from their usage entirely. A 2020 article by Med Device Online proposes the use of action priority tables in place of RPN.

Additionally, RPN and a modified fuzzy FMEA have been used to help determine the construction of dams, at least according to this paper written by Nature.com. Creating a dam can pose real ecological concerns, and teams are utilizing FMEA and RPN to determine exactly how severe those risks are.

Closing Thoughts on RPN

Understanding which risks to prioritize can make or break a business. Any deliverable or service is going to have an inherent risk. Learning how to utilize RPN as described throughout this guide is going to allow your team to hone on the problem areas as needed while minimizing potential harm to your reputation and customers.