There are two applications for using a pull system. One is to use a purchase pull system while the other is a manufacturing pull system. The formulas and calculations are similar for both so we will focus our discussion on a purchase replenishment pull system.

Overview: What is a pull system?

Pull systems establish strategically located buffers of goods within a process for either:

- Raw material

- Manufactured goods

- Purchased goods

- Finished goods

Pull systems de-couple supplying processes from consuming processes via the buffer inventory. Inventory (or part) replenishment is triggered based on consumption and customer demand (pull) versus (push) based on customer demand forecasts or assumptions.

You would use a replenishment pull system when:

- the consuming process time expectation is shorter than the time needed by the supplying process to deliver

- you have a repetitive product offering

- there is a relatively consistent demand (low variability)

This will apply equally well for purchased goods, supplies, and manufactured goods.

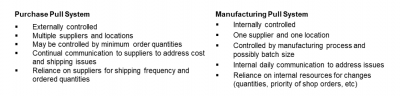

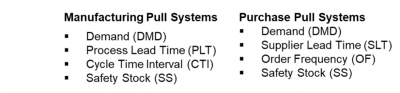

Here is a comparison of the characteristics of a purchase pull and manufacturing pull system.

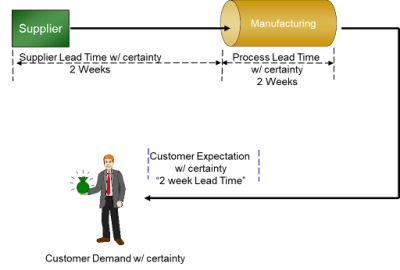

If this was the situation with your organization, would you need to implement a replenishment pull system?

The answer would be no since the consuming process has a 2 week expectation, with certainty, and the supplying process can deliver, with certainty, in 2 weeks.

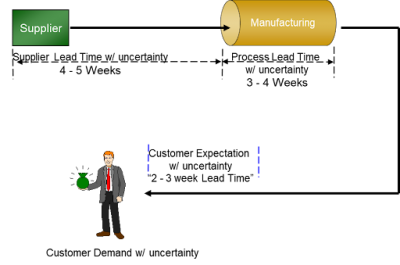

What about now?

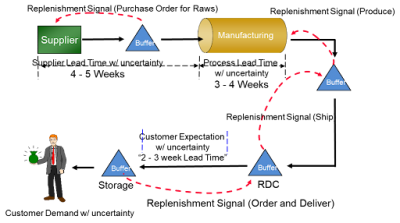

In this case, you would want a replenishment pull system because the consuming processes have an uncertain but shorter time expectation than the supplying process can deliver. This problem could be solved by putting the buffers in the appropriate locations to compensate for the uncertainty and difference in consumption and supply.

The dashed red lines indicate that, once the inventory levels in the buffers reach a certain level, a trigger will be sent upstream to start the replenishment process. These signals are triggered by the customer demand which pulls the replacement product through the system.

The factors that impact the size of the buffers are:

- average demand

- variation of demand

- lead time to order or produce

- desired level of coverage and risk for outage

- reliability of “supplier”

These are the parameters used for the calculation of the replenishment levels:

Using values for the above parameters, here are the formulas you would use to calculate buffer inventories:

(1) Kmax = Max Kanban = [(SLT x DMD)+(OF x DMD)+SS]

– Maximum inventory in the pull system loop

(2) Kmin = Min Kanban = Trigger Point = [(SLT x DMD)+SS]

– Minimum expected BOH inventory in the pull system loop

3 benefits of a pull system

Using a pull versus push system will result in many benefits both for your organization as well as your customers and suppliers. Here are a few.

1. Reduces Work in Progress (WIP)

By not producing products when there is no demand, you will reduce the amount of WIP in the system. This serves as the basis for implementing a Kanban system.

2. Reduce lead time for your customers

If you base your production on customer demand they may not have to wait until you complete your long production runs which is what you would do with a push system.

3. Reduces costs

By not having to find a place to store excess inventory or finished goods you will save money by eliminating unneeded warehouses or floor space.

Why is a pull system important to understand?

People often think that using long production runs (push) will be more cost effective than shorter and more frequent runs based on actual customer demand (pull). Here are some important considerations for using a pull system.

Differentiate between a push and pull system

It is important for you to understand the advantages and disadvantages of a pull versus push system. While there may be circumstances where you will want to use a push system, a pull system will often be the better choice.

When to properly use a pull system

The pull system works best when the consuming process time expectation is shorter than the time needed by the supplying process to deliver. It is also preferred when you have a repetitive product offering and there is a relatively consistent demand.

Flexibility of pull versus push

The pull system is more flexible to changes in customer demand than a push system. Because the push schedule is planned well in advance, it will be less flexible if customers want a different quantity or mix of products than originally planned.

An industry example of a pull system

Jeanne, one of the company’s Six Sigma Master Black Belts (MBB), was asked to help Supply Chain do some calculations for the overall inventory in their pull system and to determine the trigger point of when to place a new order. Here is the data Jeanne gathered and the calculations she made for Kmax and Kmin.

Purchase Part Number 135ABS has the following data:

Order Frequency (OF) = 15 days

Supplier Lead Time (SLT) = 22 days

Demand (DMD) = 50.0 parts /day

Standard Deviation ( s.d. ) = 12.5 parts/day

Service Level = 98% (2.055 s.d.)

(1) Determine the Max Kanban (Kmax)

Max Kanban = (SLT x Demand) + (OF x Demand) + SS

= (22 x 50) + (15 x 50) + 224

= 2,074

(2) Determine the Min Kanban (Kmin or Trigger Point):

Min Kanban = (SLT x Demand) + SS

= (22 x 50) + 224

= 1,324

* Note we will use: SS = 12.5 x 2.055 x (22)0.7

3 best practices when thinking about a pull system

Implementing a pull system can create some confusion and chaos. Here are a few hints to help make the transition a little easier.

1. Maintain discipline

Be careful of losing the discipline of your pull system. There will be some unexpected highs and lows in demand from your customers. Don’t overreact and slip into a push mentality.

2. Determine desired level of coverage

Out of stocks and not being able to deliver 100% of the time to your customers will happen. The good news is that you can decide on the probability of that happening. Your level of coverage or probability of not meeting the demand will have an impact on your calculations of buffer inventory or production runs.

3. Monitor your suppliers’ reliability

A good pull system must rely on suppliers who can deliver when promised whether it be an external supplier or internal manufacturing. Monitor their reliability to be sure it doesn’t deteriorate otherwise your pull system will become less predictable.

Frequently Asked Questions (FAQ) about a pull system

What’s the biggest advantage of a pull system for manufacturing?

It will significantly reduce waste since there won’t be as much overproduction which is one of the 8 wastes of lean.

Are there other applications for a pull system besides raw material purchases or manufacturing?

Yes. A great application for pull is with the assignment of projects. Rather than just assign a long list of projects and let the employee figure out how to manage the process, you can use a pull approach. This would create a small inventory of projects and once one is done you create a demand or pull for the assignment of another.

What are some contrasts between a push versus pull system?

A pull system starts production as a reaction to actual customer demand, while a push system initiates production in anticipation of future demand.

A pull system is one that limits the amount of work in process (WIP) that can be in the system, while a push system has no limits so overproduction and excessive inventory can be created.

Push or Pull, you decide

A push based strategy is usually recommended for products with a low level of uncertainty in demand since the forecast should give a good indication of what to produce and keep in inventory. The disadvantage is the lack of flexibility to customer demand. Furthermore, there is a likelihood of producing excessive products thus driving up costs.

A pull based strategy is usually suggested for products with some demand uncertainty and with a low importance of economies of scale where long production runs do not reduce cost. There will be reduced cost due to low WIP and greater flexibility to changes in customer demand.