Key Points

- Process time is the duration it takes for a person to work on a specific task.

- Further, it can be divided into CVA, NVA, and BVA for the duration.

- It differs from lead time as it doesn’t factor in queue times.

Your customer must wait for their product or service until all the processing has been completed. The time to complete a process step is what process time is all about. In this article, we will define process time, the benefits of reducing it, and a few recommendations on how to improve the time someone spends on a specific process task.

What Is Process Time?

The time it takes from when an item enters a process until it exits a process is called process lead time (PLT), or Little’s Law. That total time consists of the processing time at each workstation plus any waiting or queue time while in the process. Waiting is usually considered non-value-added work and should be reduced or eliminated as much as is feasible.

Process time is the actual time a person spends working on a specific item or task. That time might be customer value-added (CVA), business value-added (BVA), or non-value-added (NVA). Both you and your customers should aim to minimize that processing time so you can increase your throughput and capacity while delivering your product or service more quickly to the customer.

The first thing you might do is evaluate the work being done and eliminate any NVA. That would reduce the processing time for that step. Then you can assess whether the CVA and BVA can be improved. In any case, you will rarely want a single process time to be as fast as it can be, especially if the process is a series of sequential steps. If you do, you may be building up WIP, or work-in-process, which can slow the process down.

A traditional Lean metric known as takt time provides information as to the maximum process time allowed to meet your customer demand. Any faster and you won’t meet your customer demand. Any slower, and you might build up WIP between your process steps.

Reducing Wasted Time

There are a few approaches to maximizing your time without producing waste. One handy way of reducing wasted time is cross-training workers. This enables familiarization with different aspects of production while also minimizing downtime.

Benefits of Process Time

Since your time to process at each step drives your overall process lead time, there will be benefits to that overall process lead time if you improve your individual processing times.

Estimate of Overall Process Lead Time

The addition of all the processing times plus the waiting times will give you the approximate overall process lead time.

Identify Potential Opportunities

By analyzing the processing time of each process step, you should be able to identify where some process improvements might be. Steps of long duration might end up being bottlenecks, which will delay subsequent steps from moving the item through the process.

Process Balance

In a perfect world, you would have all your process steps working at the same processing speed. That way, you would have a balanced system with no idle time, or in-process WIP. Knowing your process time will allow you to do this analysis.

Why Is Process Time Important to Understand?

It’s important to know how long your process time is for an activity as well as the nature of the work being done.

Duration

Timing the duration of each work activity will give you insight into possible bottlenecks, excessive work content, and how long it will take to deliver a product or service to your customer.

Nature of the Work

Processing time will consist of CVA, BVA, and NVA work. You will want to analyze the work content so you can eliminate the NVA work, thus reducing the overall process time.

It’s Only an Average

Measuring process time only once will only provide you with a single snapshot of how long the activity is taking. You will want to measure it a number of times so you can calculate the average process time as well as the variation of the time. That will provide you with a more accurate picture of what is going on.

An Industry Example of Process Time

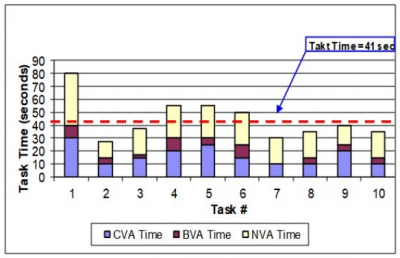

An electronics company had an assembly line consisting of 10 workstations where components were assembled into a single finished product. As customer demand increased, the company found itself falling behind in its ability to deliver products on time. The company’s LSS Black Belt did a time study on how long each task was taking as well as the nature of the work. She also calculated the takt time and found it to be 41 seconds. That is, each task cannot exceed 41 seconds or the customer demand will not be met.

Below is the takt time chart that she created. You will notice that the processing time for tasks 1, 4, 5, and 6 exceeds 41 seconds. There is quite a bit of non-value-added work in all of the tasks. Especially in task 1, which takes almost double the takt time to complete. You may also notice that task 2 is the quickest. There is a lot of idle time in that task waiting for task 1 to be completed.

The Black Belt employed a number of different strategies to improve the process. First, she did a job sharing between tasks 1 and 2 to reduce the high processing time of task 1. Then she eliminated the NVA work. Finally, she now had the choice to combine tasks and reduce the number of workstations.

Process Time Best Practices

Calculating your process time requires some fundamental mathematical and statistical skills. Keep these tips in mind when you’re seeking to reduce your process time so you can reduce your overall process lead time.

Multiple Readings

Time multiple observations of a task and calculate the average and standard deviation so you have a true picture of the central tendency and variation of how long that task takes.

Distinguish Between BVA, NVA, and CVA

Your ultimate goal should be to reduce the amount of processing time for a task. Your first step is usually the elimination of the NVA.

Be Sensitive to the Workers Involved

People tend to get nervous and suspicious if they see you observing them and timing their work. Be sensitive and explain what you are doing and why. They can alter their usual work pattern and give you a false reading if they become distrustful.

Other Useful Tools and Concepts

Looking for some other extra tips and tricks? You might want to look into how your organization can achieve world-class quality. Reaching for the stars isn’t an unattainable goal, as you’ll find our article going into the matter.

Further, understanding how to deliver quality is an entirely different matter. For that, you’ll want to reach for the likes of a quality operating system. This is a Lean approach to manufacturing that’ll see customer confidence soaring with your deliverables.

Conclusion

The time to process an object is the actual time it is being worked on, whether the work is value- or non-value-added. The total of your processing time plus the time waiting and doing other non-processing activities will be the time it takes from start to end of any object that goes through your process.

You should strive to reduce your process time so you can deliver products and services faster to your customers while still maintaining high quality.