Key Points

- Making stable processes can reduce waste.

- Stable processes are created by minimizing the impact of variation on a process.

- Don’t mistake stable processes for capable processes.

To maintain an efficient and productive process, you need stability. Over time, a process can become unstable due to either common cause variations or special cause variations. The stability of a process should not be confused with process capability. A process can be stable in producing poor results, but not capable of the desired outcome.

Overview: What Is Process Stability?

Process stability is when a process in manufacturing is predictable over time, and the outcomes are as expected.

Run charts are commonly used to get a clear picture of whether a process is stable or not. By plotting process performance characteristics daily over some time, you will be able to see if the process is consistent from day to day. If the plots do not look similar and there are a few outliers, you can then take steps to find the problem and implement a fix.

3 Benefits of Process Stability

As one of the most important concepts in Six Sigma, confirming the stability of a process offers several benefits.

1. Higher Yields

With a stable process, production is smooth, quality products are produced in a predictable quantity, and daily quotas can be met. A stable process is less likely to experience unexpected delays and downtimes.

2. Ability to Catch and Fix Variations

By utilizing a run chart, you can see how the process is changing from day to day. If you notice there is something out of the control zone, you can investigate and come up with solutions to fix the problem during already scheduled downtime and prevent it from happening again.

3. Better Efficiency

When you have stability in your process, things run as expected in the shortest amount of time possible. A stable process also reduces material waste, which leads to a more cost-effective and environmentally friendly process.

What Is the Difference Between a Capable and Stable Process

Stable processes are ones marked by stability, fitting within the confines of established control limits. A capable process fits the stated control limits but always meets customer specifications. A stable process can create subpar products, but a capable process always will turn out quality.

Why Is Process Stability Important to Understand?

Understanding the stability of your process is important because it can directly impact your company’s bottom line.

Reduce Costs

A stable process will waste a lot less material and time. By reducing unexpected downtimes and the amount of materials needed, you can significantly reduce your overall costs.

Increase Customer Satisfaction

Customers expect products to be delivered as promised. By monitoring your process and ensuring that it is stable, you can ensure you meet delivery deadlines and keep your customers happy and coming back.

Improved Process

Without a stable process, you are not able to predict the performance of the process when there is a special cause variation. A special cause variation is an indicator of a significant disturbance in the process. When you monitor stability, you can catch these variations and improve your process.

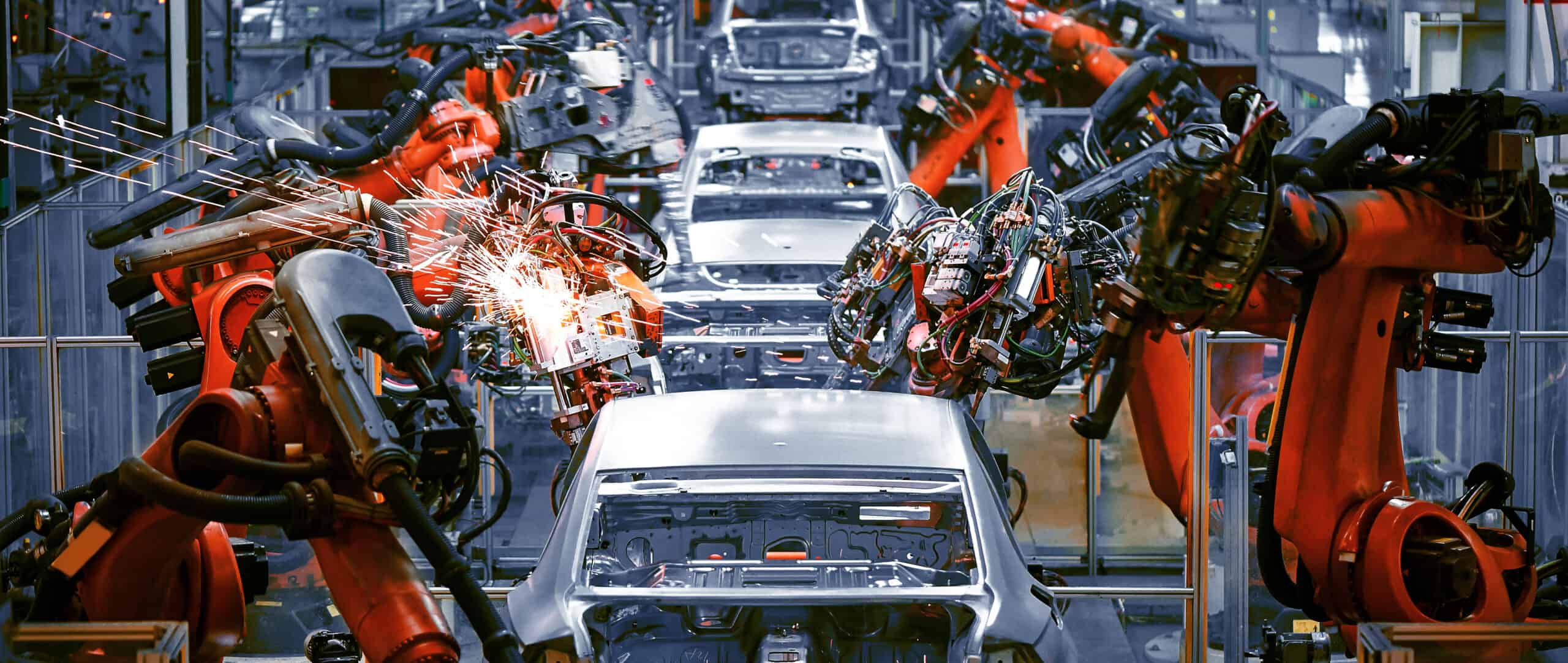

An Industry Example of a Stable Process

Let’s say you run a business that mails welcome packages after a customer signs up. The customer expects to receive that package within 10 days. Any longer than that, and the process is considered unstable. This unstable process can result in issues down the line in the form of unsatisfied customers and additional calls to the customer service department that can increase costs.

3 Best Practices When Thinking About the Stability of Your Process

When thinking about the stability of your process, you should implement the following best practices.

1. Put the Focus on the Customer

Everything about your business, right down to the manufacturing process, should revolve around what your customers’ needs are. All processes and changes should be made to the quality expectations of your customers, and that might just mean longer manufacturing times.

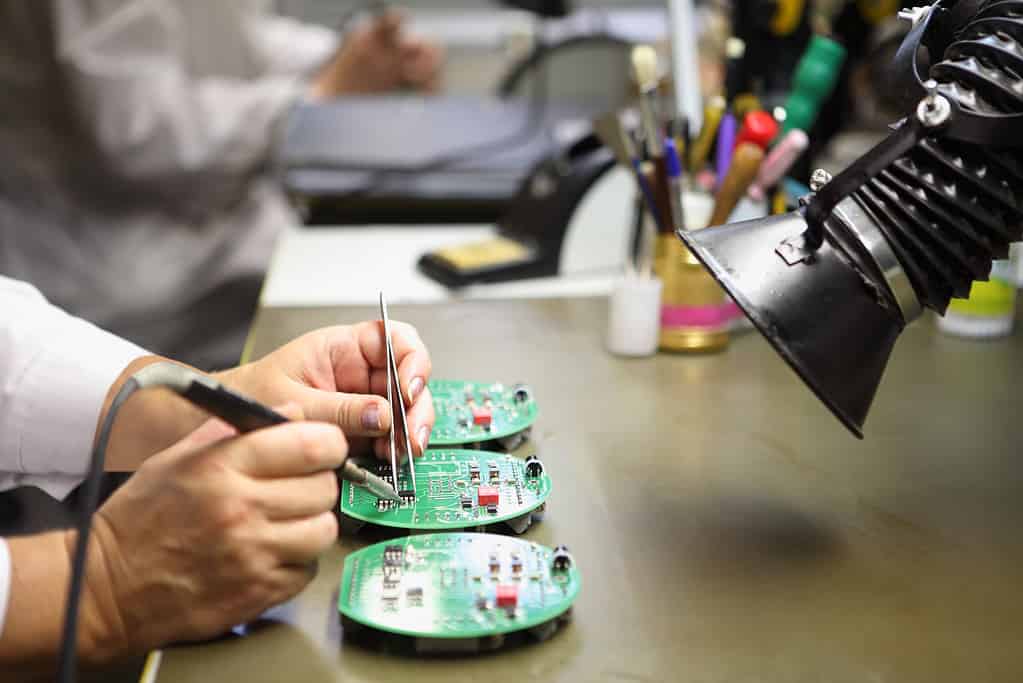

2. Eliminate Non-Value-Added Steps and Waste

A non-value-added step is something that does not directly affect the final product or anything that doesn’t meet your customer’s expectations. Waste comes in many forms, including inventory, waiting, overproduction, not utilizing capable talent and extra processing steps.

3. Map Out the Process

To see where waste and non-value-added steps are, it is a good idea to map out your entire process, including workflows, materials, time spent at each stage, etc.

Other Useful Tools and Concepts

Looking for some other tips and tricks to get you going? You might want to look into how bimodal distributions work in the context of your statistical analysis. These can indicate if you’ve got something amiss in your data sets.

Further, you might want to look into process entitlement. If your production is exceeding expectations, it certainly helps to reap the benefits of quality output.

Conclusion

By creating a stable process, you can improve your output, and customer satisfaction, reduce waste, and have a foundation for a process that you can continually improve upon.