© Perfect Angle Images/Shutterstock.com

Key Points

- A process control plan acts as a map to continue on your process improvement.

- They can take many forms, depending on the needs of an organization.

- It effectively has many different components, in the event of process degradation.

Process improvements have a tendency to slip back to how things were done, just like a stretched rubber band snaps back when released. The process control plan will help prevent this from happening.

Let’s learn more about how that can be done.

Overview: What Is a Process Control Plan?

©Ground Picture/Shutterstock.com

The purpose of the process control plan is to be sure the process improvements made by your Six Sigma improvement team can be sustained over time. The process control plan will be developed during the Control phase of DMAIC. It is a written summary that describes what’s needed to keep your process at an improved level.

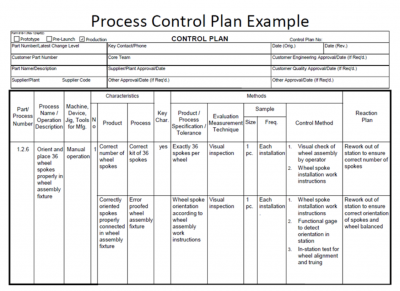

The control plan will usually display the improved process map, key process variables, and the reaction plan if the improved process starts to degrade.

While there are a variety of control plan formats, some of the key elements should include:

- Process flowchart: A visual representation of the high-level process steps for the improved process.

- Critical metrics: Key measurable characteristics of a product or process whose performance standards or specification limits must be met in order to satisfy the customer. These are often referred to as CTQs (critical to quality).

- Measurement method: Documents the method used to collect the process measurement or CTQ.

- Sample size: The sample size chosen for measurement.

- Measurement frequency: Identifies how often the data should be collected.

- Reaction plan: A documented process for correcting deviations from the desired state including the who, what, when, and where of the actions taken.

Why Should You Use One?

So, why plan out any part of your process? You don’t go on a road trip without a map, do you? Simply put, a process control plan is a way to keep your process improvement streamlined. Further, it gives you the means and capability to account for any out-of-spec or degradation you might experience when implementing said plan.

An Industry Example

As the project team was finishing up the Control phase, the Master Black Belt assigned to the team provided a quick tutorial on how to create a process control plan. She showed them the following template as an example of how they can develop one for their project:

Other Useful Tools and Concepts

While we’ve talked at length about planning, there are still many other helpful concepts you can apply to your organization today. Speaking of process improvement, why not consider learning about the 7 wastes of Lean? These wastes are present in any organization. Further, they can greatly impact your production.

Additionally, you might also consider learning about first-time yield. While it can seem somewhat dense at first glance, this will allow you to pinpoint defects before they get out of control.

Conclusion

So, do you need a plan? Processes are complex and dense subjects to account for, but having plans in place can help you keep things under control. As such, don’t get caught on the back foot, start planning today.

The image featured at the top of this post is ©Perfect Angle Images/Shutterstock.com.