The Toyota Production System, was developed around the elimination of the three types of deviations that represent the inefficient allocation of resources. The three types of deviations are muda, mura, and muri. Muda deals with waste and is often defined by the 7 wastes of lean. Mura is concerned with inconsistency and variation and may drive and lead processes to muda.

Muri refers to something being overburdened such as equipment or operators having to run at a higher or harder pace with more force and effort for a longer period of time than equipment designs, and appropriate workforce management allow. Over time, muri can result in employee absenteeism, illness, and unplanned breakdowns of equipment.

Overview: What is mura?

Mura is a Japanese word meaning unevenness, non-uniformity, and irregularity. It is a well known concept in Six Sigma that variation is not desirable. Mura can be the driver for some of the 7 wastes of lean often referred to as the phrase TIMWOOD. In other words, Mura drives and leads to Muda.

Mura can be avoided through the use of Just-In-Time manufacturing or by using a Kanban system which can limit overproduction and excess inventory. The key concept of a Just-In-Time system is delivering and producing the right part, at the right amount, and at the right time.

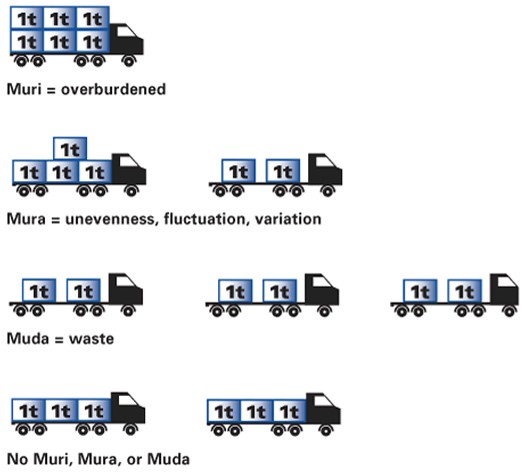

As an example, a transportation company must move 6 tons of product to a customer. The graphic below illustrates muda, mura and muri.

An industry example of mura

The company’s Six Sigma Black Belt (BB) was facilitating an improvement team seeking to reduce the variation or mura in a process. They narrowed in on a few issues which included:

- Variation in production schedule which was not caused by customer demand but by the production manager

- Uneven work pace or takt time in an operation causing some operators to rush and then wait while others had a lot of idle time

Frequently Asked Questions (FAQ) about mura

What is the definition of mura?

Mura is a Japanese term meaning irregularity or a lack of uniformity. Mura is often a driver which could result in process waste known as muda. The irregularity or variation in production can result in lost product and wasted time.

Can mura be eliminated from the process?

No. When you are producing different products, they often require different materials, methods, or processing times. This is even more prevalent in project work, where every project is different. But variation can be reduced.

Why is mura a bad thing?

Most Lean Six Sigma improvement efforts strive for standardization, reduction of variation and optimization of the process. Variability can lead to defects, waste, and lower quality.

Reasons for mura can include:

- variation caused by people doing the process differently

- machines having different operations and outputs

- raw material variation from different suppliers

- the way people gather data and analyze results