You might have some great improvement ideas, but technology hasn’t quite caught up. Or, you need to get something in place in the short term, with further improvements planned for down the road.

This article will define and describe how to manage your multi-generational product planning (MGPP), the benefits of doing improvement this way, and some recommendations for optimizing this process.

What Is MGPP?

MGPP is a process improvement approach that helps you focus your team’s energies on a manageable project that can be completed in a relatively quick period. Many improvement ideas might be beyond the current state of technology or business readiness. Yet, there are benefits to be gained by starting to think about and plan for your future state while implementing what you can now. Your MGPP is a living document that adapts to the changing nature of your business.

Your MGPP will consist of three elements: vision, process generations, and technology and platforms. Here’s a brief description of each:

- Vision: This is your overall goal or problem statement. What do you want to accomplish? Why? It can also be metrics with targets. Develop a reasonable scope that is achievable and has an adequate level of impact. You will have a short-term vision and a long-term vision.

- Process generations: Develop a series of releases where each release is characterized by distinct combinations of features or levels of performance. Each generation should be an incremental build on the previous generation.

- Technology and platforms: You should be able to execute your first-generation MGPP with current technology as well as identify needed technological developments for each subsequent generation. You should determine what is required from a technology standpoint to execute the vision. You should also include any people’s requirements to support future improvements and your ultimate vision.

Benefits of MGPP

By not tackling your project improvements in one large chunk, you’ll be better able to manage it with bite-size pieces of your MGPP.

Prepare for the Future

Since you have considered the future, the team will be less likely to make decisions that are incompatible with future generations.

Prevent Delays

Instead of having an extended development time for the project, you can add new ideas to future generations of the project, allowing you to keep your first-generation improvement plan focused and efficient.

Encourage Parallel Development

The organization can be working on new technologies that are needed for future generations while the first-generation process is implemented — and realizing benefits.

Why Is MGPP Important to Understand

Since you’ll be planning for future states, you’ll need to understand some of the complexities of doing that.

Complexity

Your ability to break down all possible improvements into a timed series of future releases will allow you to capture some benefits now and be linked to your future opportunities.

Relevancy

It will be important for you to understand your current capabilities and have a viable vision of what the future will look like.

Linkage

Understanding the linkage between your vision, process generations, and future technology and platforms will be important so you can have a smooth transition between the various generations of improvements.

An Industry Example

A manufacturer of laminated glass has begun its implementation of Lean Six Sigma. One of the early teams came up with an unmanageable amount of recommendations since many spanned future generations of possible technology and process improvements. The plant manager, Clint, suggested that the team develop an MGPP to sequence the improvements as corporate technology develops new machines with greater capabilities.

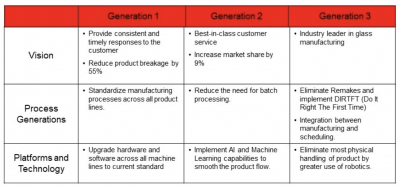

Here is the final MGPP that the team agreed was a viable solution for melding current and future improvements. They are currently completing the Generation 1 improvements.

Best Practices With MGPP

Since an MGPP may span a number of months or years, there are a few things that you can do to keep the process moving along and coordinated.

Scope

Keep the scope of each generation manageable and tight enough so you can complete the activities in a reasonable amount of time, yet enjoy sufficient benefits to keep the enthusiasm going across all generations.

Replication

Keep your eyes open for the replication of some of your improvement ideas across other parts of your business. There can be benefits for those other parts of the business without the necessary effort.

Communicate

You will need to communicate with any process owners and/or stakeholders so they know what has happened, what is happening, and what will be happening. You will likely need their input and support, so keep them in the loop.

Other Useful Tools and Concepts

There are plenty of things to keep in mind when planning your production. Accounting for the natural drift and randomness inherent in any production means setting good natural tolerances. These work directly in conjunction with your control limits to paint a whole picture of what to expect from your processes.

Additionally, if you find yourself in need of regaining customer trust, it pays to know about the clean point. Our guide covers how it works and why it matters, which is a wonderfully helpful tool for getting back on track with your customers.

Conclusion

Multi-generational product planning is a staged improvement process that implements changes over a specified timeline. Improvements are released as your business environment evolves.

Your future states will consider the evolution of your organization’s vision, processes, and technology. You will need some strong planning and coordination to keep the momentum of improvement going over what could be an extended period.