Key Points

- COPIS is a high-level visualization of your processes.

- Unlike SIPOC, it focuses on the customer first.

- It works well with DMAIC and DMADV alike.

COPIS stands for customer, output, process, input, and supplier. COPIS is a high-level extended view of your process. Let’s consider some of the benefits of using COPIS as well as some hints on getting the most from your diagram.

What Is COPIS?

The COPIS terminology is a revision of the original model called SIPOC. SIPOC is a high-level process map of your extended process. As you may have noticed, COPIS is just the reverse spelling of SIPOC. Let’s explore what each letter stands for.

COPIS and/or SIPOC are used in the Six Sigma DMAIC methodology, usually in the Define stage. The letters of COPIS stand for customer, output, process, input, and supplier.

Your first step would be to define the process you wish to diagram. What is the scope you wish to include in your COPIS? You should have a definable start and definable stop for the process in question. These process boundaries can be narrow or wide depending on whether you’re looking at a macro or micro process.

Defining COPIS

Here’s the sequence to follow:

- Customer: This would be the next person or organization you hand your output to. It could be the next functional area. It could be the actual external customer. All of your outputs go to some customer, somewhere, who has expectations and requirements for your output.

- CTQs (Critical to Quality) or requirements: These are the key metrics your customer might use to evaluate whether your process is producing output that meets their requirements. It’s optional to actually put it in a separate column of your COPIS diagram, but be sure to capture it somewhere.

- Output: Next, identify the outputs your customer wants, needs, and values.

- Process: Your COPIS will include a high-level description of the process that would meet your customer’s requirements. Describe your process in 5-7 high-level steps.

- Inputs: These are the things your process needs to start and produce your outputs, perhaps including the 6 Ms. These would refer to such things as people, materials, equipment, procedures, money, utilities, environmental conditions, data, and anything else your process needs to function.

- Suppliers: This is where your inputs come from. They may be internal or external suppliers.

Getting Started

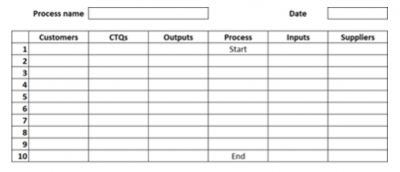

Here is a COPIS template you can use to map your process.

Image source: sixsigmaninja.com.

To summarize, in COPIS, you start with your customer and identify the key metrics (or CTQs), the outputs that will meet their needs, the process that will deliver the outputs, the inputs the process needs to function, and the suppliers you get them from.

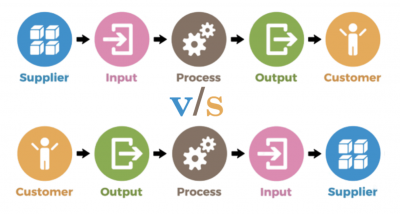

Here’s a visual comparison of SIPOC and COPIS.

Image source: niqcgroup.com.

COPIS is a more customer-focused approach than SIPOC and can ensure your customer’s CTQs, or requirements, are being considered at the beginning. Looking at the customer before you look at the process ensures that you prioritize your customer’s needs instead of starting with your process and trying to make everything fit into that.

Benefits of COPIS

COPIS allows you to view your extended process from a macro perspective before drilling down. Some of the benefits of this wider view include the following.

Starting With Customer Focus Hones In on Their Needs

COPIS is a reverse approach to the better-known SIPOC. SIPOC starts with the existing process and then moves to your customer. COPIS starts with your customer and moves to the process needed to satisfy your customer’s needs.

Great Tool for an Executive Overview

The COPIS diagram can usually be created on a single piece of paper. This provides a nice overview of the process to senior leadership as well as team members who may be working on an improvement project for that process.

Extended Process

Most process mapping techniques just look at the micro process. This extended view provides a broader context and understanding of the larger process.

Why Is COPIS Important to Understand?

For such a simple tool, COPIS can provide good information and insight.

The Customer Is the Driver

COPIS lets the customer drive what the process should be to meet your customer CTQs.

Everything Is Linked

All the sections of COPIS are linked. The desired outputs and CTQs come from the customer, which connects to the needed process, which requires specific inputs that are received from a supplier. With so many moving parts, it’s important to have a cohesive way to view all of the elements and make sure they align.

Plays Well with DMAIC and DMADV

COPIS and SIPOC can be used in the Measure phase of the DMAIC methodology. They can also be used in the DMADV methodology, which is similar to DMAIC but is applied to design and redesign projects rather than for incremental improvement projects.

Do You Need Software to Make One?

Honestly, you can get by with just a sheet of paper and a pencil. Software can make it easier, thanks in part to the use of standardized symbols and cleaner workflow. However, if you’re in a pinch, there’s no need for specialized software to get rolling.

An Industry Example of COPIS

From prior surveys, the marketing department of a food products company felt they had the opportunity to produce a product that would fill a gap in the marketplace. They asked their Master Black Belt, Gail, whether she had a design process that might work faster than their usual approach. Gail said she liked QFD and would be glad to facilitate the team in using the tool.

They first gathered extensive Voice of the Customer (VOC) information as to their requirements for the new product. Then they built their HOQ. This required using their gathered customer feedback, determining process and physical attributes of the product, correlating them, and setting targets. They also gathered competitive information about other similar products.

Cascading down from the HOQ, they engaged manufacturing to help with phases 3 and 4 to develop specifics around the product and the manufacturing process. Finally, they brought in the quality control group to help set the specifics of the QC requirements and processes.

In the end, they produced a successful, high-quality product that met the VOC requirements.

COPIS Best Practices

Since COPIS is used in the early stages of a project, it should be clear and easily understood. Here are a few ways to make that happen.

Involve the Team

The collective experience and knowledge of the team in defining the COPIS extended process is required to capture and describe all the elements of the process.

Don’t Be Biased

Since COPIS is supposed to be customer-focused, don’t allow yourself to be biased by the existing process. Focus on the customer needs and CTQs to come up with the process, not the other way around.

Consider All Possible Process Outputs

Don’t just focus on the expected good outputs of your process but also consider any defects, errors, waste, scrap, pollution, or any other output that is an outcome of your process even if it’s not desired.

Other Useful Tools and Concepts

Looking for other ways to bolster your process design? You might want to learn about some of the common pitfalls that come with using SIPOC. As one of the most common tools used in Six Sigma, SIPOC has plenty of documentation surrounding it. However, you can fall into certain traps when using it.

Additionally, learning how to get your team prepped to use a SIPOC diagram is instrumental in guaranteeing project success. Learn all about how this works in our comprehensive guide on the subject.

Conclusion

COPIS starts with and focuses on, your customer and their needs. By doing so, a team can gain insight into what is truly important to your customer. After clearly defining the wants and needs of your customer, the related outputs can be identified, allowing you to then develop the process to create those outputs. From there, you can determine what inputs the process requires and what supplier they will come from.