Once you have completed your process improvement, there is a tendency to forget about it and assume the changes will continue. This is often not the case. By creating and managing your control plan, you will increase the probability that the gains you made will be sustained.

Let’s see how this can be done.

Overview: What is a control plan?

The purpose of the control plan is to ensure performance improvements made by the project team are sustained over time. You will develop and execute the control plan during the Control phase of DMAIC. It is a written summary that describes what is needed to keep an improved process at its desired level. This includes actions that should be taken if measures are outside the specified range, and reactions needed to ensure process owners sustain the gains.

Generally speaking, the control plan will display the improved process map, key process variables, and the reaction plan should the improved process start to degrade.

While there are a variety of control plan formats, some of the key elements should include:

- Process flowchart: A visual representation of the high-level overview of the process steps for the improved process.

- Critical metrics: Key quantifiable and measurable characteristics of a product or process whose performance standards or specification limits must be met in order to satisfy the customer. These are often referred to as CTQs (critical to quality).

- Measurement method: Used to document the method used to collect the process measurement or CTQ.

- Sample size: Size of the sample chosen for measurement.

- Measurement frequency: How often the data should be collected.

- Reaction plan: Any corrective actions taken for correcting deviations from the desired state including the who, what, when, and where of the actions taken.

An industry example of a control plan

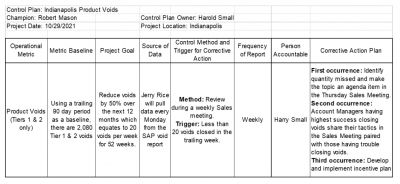

The sales team recently completed a project seeking to reduce the number of voids of their key products on customer shelves. A void was defined as the absence of a specific product on a customer’s shelf. If there is no product, the customer can’t buy it, and they may switch to a competitor’s product.

After the team worked on recommended improvements and implemented their changes, a control plan was used to make sure the changes were sustained.

Below is a simplified control plan used by the group:

Frequently Asked Questions (FAQ) about a control plan

What are the three levels of reaction that should be in my control plan?

The first level would be compensation and adjustment if you didn’t know the root cause of the change. The second level would be to do a temporary correction if you know the root cause. Finally, the best reaction would be to prevent any further occurrence by implementing a poka- yoke, or mistake-proofing remedy.

What is the purpose of a control plan?

Simply stated, the purpose is to maintain or sustain the gains of any improvements you have made in your process.

When is the control plan developed?

Control plans are usually developed in (surprise!) the Control phase of the DMAIC methodology. Once recommended improvements have been made and implementation begun, the control plan will help you identify if, when, and how you should react to any undesired deviations from your planned improvements.