A buffer can be simply defined as something that serves as a protective barrier. Let’s see how this might apply in the context of technology and computing as well as manufacturing.

In the context of technology and computing, a buffer is a temporary storage area that holds data while it is being transferred from one place to another. It acts as an intermediate step to smooth out differences in data transfer rates between different devices or processes.

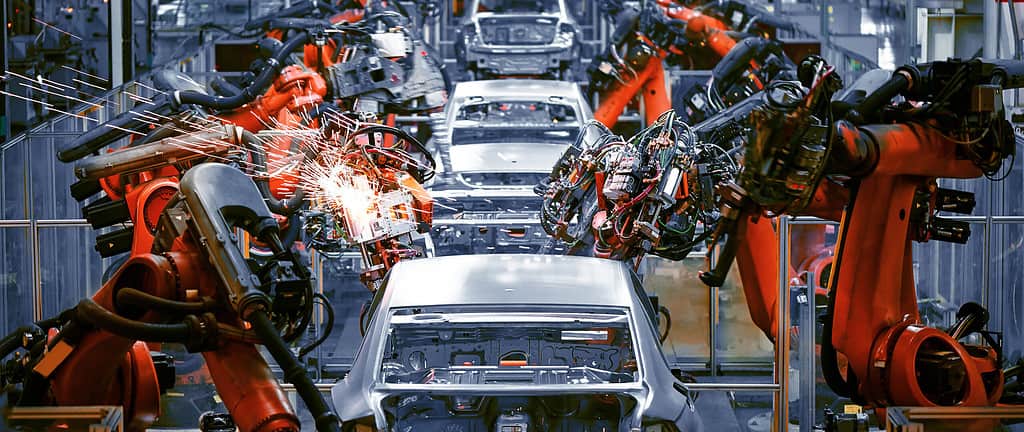

In the context of manufacturing, a buffer refers to a strategically placed inventory or resource stockpile that acts as a cushion to absorb variations in production or demand. Buffers are used to prevent disruptions in the manufacturing process and ensure a smoother flow of materials, components, or work-in-process (WIP) items.

Overview: How Are Buffers Used?

©Depiction Images/Shutterstock.com

Buffers in computing are commonly used in various scenarios, such as:

- Input/Output (I/O) Buffers – When data is read from or written to a device, such as a hard drive or network connection, it is often stored temporarily in a buffer. This buffer helps to manage the speed differences between the device and the processing unit, ensuring a smooth and efficient transfer of data.

- Memory Buffers – Buffers are used in computer memory to temporarily store data during operations. For example, when processing large files or performing complex computations, a buffer can hold intermediate results or sections of the data, allowing for more efficient processing.

- Video and Audio Streaming – Buffers play a crucial role in streaming media content, such as videos or music. The data is typically downloaded or received in chunks and stored in a buffer before being played back. This buffering helps to prevent interruptions or buffering delays when network conditions fluctuate.

Buffers in Manufacturing Can Take Various Forms, Including:

- Raw Material Buffer – This buffer is maintained by storing an excess quantity of raw materials or components required for production. It helps to mitigate supply chain uncertainties, such as delays in material delivery or unexpected spikes in demand.

- Work-in-Process (WIP) Buffer – This buffer exists between different stages of the manufacturing process. It allows for a certain amount of inventory to accumulate between workstations, ensuring that any delays or interruptions at a particular stage do not halt the entire production line.

- Finished Goods Buffer – Once the manufacturing process is complete, a buffer of finished goods may be maintained to accommodate fluctuations in customer demand. This buffer stock helps to meet unexpected orders or compensate for production delays.

The above is often referred to as a Pull System.

An Industry Example of a Buffer

Let’s consider a bottle fill line that involves multiple workstations, each responsible for a specific task in the filling process. The manufacturing manager created a WIP buffer between each workstation. The purpose of the buffer was to accommodate variations in processing times, equipment availability, or unexpected delays. It ensured a continuous flow of work and prevented disruptions from occurring throughout the production line.

The fill line had three workstations: A, B, and C. After completing their respective tasks, the bottles moved from workstation A to B and then to C. To create a buffer, a certain amount of inventory is allowed to accumulate between the workstations.

If workstation B experienced a delay due to equipment malfunction or a temporary shortage of resources, the buffer between A and B would absorb the delay, allowing workstation A to continue operating and preventing the entire fill line from coming to a halt. Similarly, if workstation C encounters an issue, the buffer between B and C will provide a cushion, ensuring that workstation B can keep functioning.

The size of the buffer is determined based on factors such as expected processing times, variability in fill rates, and the overall system’s capacity. By strategically using WIP buffers, the company was able to maintain a steady workflow, handle fluctuations in demand, and optimize its production processes.

Frequently Asked Questions (FAQ) About Buffers

Here are some frequently asked questions about buffers:

What Is a Buffer in the Context of Computing?

In computing, a buffer is a temporary storage area that holds data while it is being transferred between different components or processes. It helps to manage differences in data transfer rates and ensure smooth and efficient communication.

How Do Buffers Contribute to System Performance Optimization?

Buffers contribute to system performance optimization by decoupling components with different processing speeds, allowing them to operate independently. By temporarily storing data, buffers enable efficient data transfer, minimize latency, and help balance the flow of information between different parts of a system.

How Are Buffers Utilized in the Manufacturing Industry?

In manufacturing, buffers are strategically placed inventory or resource stockpiles that help absorb variations in production or demand. They ensure a smooth flow of materials, components, or work-in-process items, preventing disruptions in the manufacturing process and improving overall operational efficiency.