Are you struggling to figure out the cause of a problem in your current project? Implementing the 6Ms in your problem-solving sessions might just be what you need. While these tools can seem like more jargon, there is a definite benefit to using them. So, with that in mind, it is certainly worth exploring how these tools can impact your projects.

Overview: What are the 6Ms?

The 6Ms and other similar variations are tools you can use to categorize your process inputs. Usually, these tools are used in the context of looking for and finding the possible root cause of your process variation or problems. Further, It’s flexible enough that you can use it in any functional area across myriad applications.

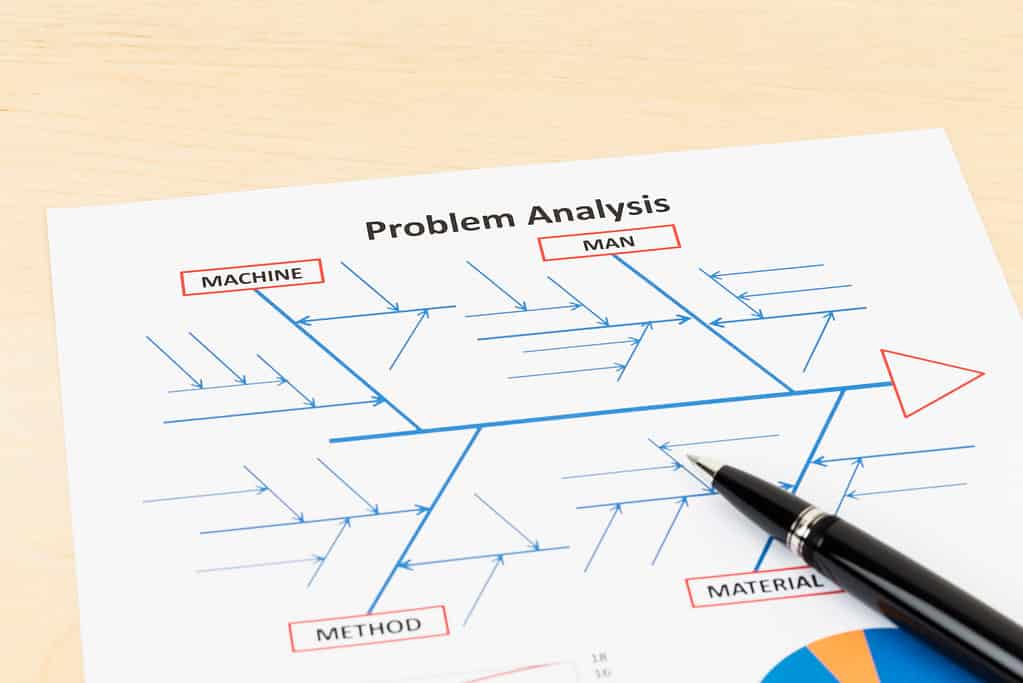

The format in which you use it will usually be the cause and effect diagram, also known as the Fishbone Diagram or Ishikawa Diagram. The standard format for these diagrams is:

Image source: Mudamasters.com.

Although you will see the 6Ms in different sequences, the definition of the Ms will be the same. The 6Ms are:

- Method: The process steps you need to produce an output or deliver a service.

- Machinery: Machines and tools that you need to produce an output or deliver a service.

- Material: The raw materials, consumables, or assemblies that you need to produce the output or deliver the service.

- Manpower: The people in your process.

- Measurement: Data, KPIs, inspection results, and any other measures that you take of the process inputs, transformation process, and process outputs.

- Mother Nature: Environmental conditions both controllable or random that you have both internal and external to your process.

Alternative Interpretations

In some versions of the 6Ms, you will see the word “Milieu” used instead of Mother Nature. While the 6 Ms might be a great mnemonic to remember the process elements, today you will often see the 6Ms represented as 3Ms, 2Es, and 1P. These are described as Method, Equipment, Material, People, Measurement, and Environment.

You might see the 5Ms and one P where the Machinery and Mother Nature are kept, but Manpower becomes People. Despite the variation in terms and the possible confusion, you can see that the concepts and elements are consistent.

You will also see the use of the 5Ms where Mother Nature is dropped from the list. In Marketing, the 6Ms may be defined as Market, Message, Media, Money, Manage, and Measurement. In the 8Ms version you might see Management and Maintenance added to the list of 6Ms.

While you will frequently use the Fishbone diagram in a manufacturing environment, the concept of root cause analysis can apply to non-manufacturing and transactional processes as well. Since Machinery and Material may not be as applicable to a non-manufacturing process, you might see the use of People, Policies, Processes, Training, and Communication as the primary bones of the Fishbone Diagram.

Regardless of the words used to describe the process elements, the methodology and approach to searching for root causes remain the same.

3 Benefits of Using the 6Ms

The simplicity of your use of the 6Ms to search for root causes makes this a very beneficial approach for several reasons.

Provides a Framework

One of the first steps you do when creating a Fishbone Diagram is brainstorming. The 6Ms provide the format and context for what you want to focus on in your brainstorming.

Gives Focus

During a root cause analysis, you may find yourself diverting to topics and discussions that are not relevant to the problem at hand. The use of the 6Ms gives you a basis for reining in that discussion and staying on task.

Allows for a Deeper Dive

One of the critical steps in doing root cause analysis is to continue to ask the question “What causes that?” This drilling down is what gets you to the real root cause. By drilling down under each of the Ms, you will increase your probability of finding the true root cause.

Why Are the 6Ms Important to Understand?

The 6Ms are the most common format for doing root cause analysis. To properly use a Fishbone Diagram and do root cause analysis, you will want to understand what they mean and how to drill down under each of the Ms.

Basis for Doing Root Cause Analysis

The 6 Ms are the most commonly used terms in the context of doing root cause analysis with a Fishbone or Ishikawa diagram.

Provides Broad Perspective

The root cause of a process problem may be due to a combination of factors. By using all 6 Ms for your analysis, you will cover the range of the most likely sources of why something in the process is not working as it should.

Simplicity of Use

The 6Ms can take a complex problem and break it down into a small number of categories and make it simpler for you to understand the relationship between the process inputs and variables.

An Industry Example of the 6Ms

The Director of Sales for a large machinery manufacturer noticed an increase in the number of customer complaints about incorrect invoicing coming from the Billing department. Although the company had previously used the 6Ms approach to address manufacturing issues, the Billing department decided to use it for one of its recurring problems.

Since most of the employees in the department were female using computers, they decided to change a few titles of the 6Ms by changing Machinery to Equipment, Manpower to People, and Mother Nature to Environment.

The team first hung up a large piece of butcher paper on the wall and handed out a package of sticky notes to everyone. The first step was to define the problem in the head of the fish. Using their sticky notes, they brainstormed the possible causes of each M and wrote those on the diagram.

Drilling down under each M was the next step of the process. The first-level causes and subsequent second-level causes were organized in a hierarchical sequence. Once the same cause started to appear on multiple branches or Ms, they realized that they possibly had their root cause.

They collected some data to confirm that these were the root causes. The team then developed mitigation and improvement recommendations to reduce the number of invoice errors.

Real-World Example of the 6Ms

So, who is using the 6Ms at their organizations? While we can look at our organizations, seeing how big names in their industries are addressing root-cause analysis can be inspiring. Xerox is no stranger to business success, especially considering they’ve been around since 1908.

Xerox is a real-life Cinderella story when seeing how the 6Ms and Six Sigma methodology have transformed an organization. Implementing the 6Ms has allowed Xerox to stay afloat in the modern era, well past when speculators thought they’d remain relevant.

By implementing this tool, Xerox navigates difficult issues and remains one of the leading tech companies in the United States.

Best Practices When Thinking About the 6Ms

Your use of the 6Ms in the context of root cause analysis and a Fishbone Diagram is conceptually simple. There are a few best practices that will help you make your efforts more efficient and productive.

Relevancy

Be sure the terminology of the 6Ms fits the nature of your problem and root cause analysis. This will be more important if you are applying the technique to a non-manufacturing problem.

Keep Drilling Down

You will rarely uncover the root cause associated with the 6Ms during your first pass of possible causes. Keep drilling down until the same potential cause starts to appear under multiple M branches.

Keep an Open Mind

When you brainstorm your possible root causes, remain open and nonjudgmental to encourage free participation by your team members. Most of the time, the true root cause will not be obvious — otherwise, you would have solved the problem already.

Other Concepts You’ll Want To Check Out

While you might have mastered the 6Ms, there are other concepts to keep in mind. As such, you’ll want to keep I-P-O models in mind. These handy models allow you to sketch out a process before involving more detailed tools.

Additionally, you might also want to learn and master the 7 QC tools. These handy tools readily aid in problem-solving and root-cause analysis.

In a Nutshell, What are the 6Ms?

The 6Ms is a description of the most common process inputs or factors. They are used to help identify the possible root causes of a problem. The Fishbone Diagram is the most common format for the use of the 6 Ms.

The name of the 6M terms may be changed to reflect the specific nature of the process that you are working on. Machinery is often changed to Equipment. Manpower is often changed to People. In non-manufacturing or transactional processes, the 6M terms may be discarded and substituted with terms such as Policies, Procedures, Communication, and Training. The name of the term is less important than the process of the root cause analysis.