You are probably familiar with the term 5S in the context of Lean Six Sigma. But, what about the term 5Z. Let’s learn a little more about what that means.

The 5Z’s provide the principles and guidelines for achieving 5Z Accreditation. The 5Z process uses the Genba (Gemba) Kanri principles to maintain, evaluate, promote, and improve control of your process. The goal of the 5Z methodology is to eliminate any defects and errors which might occur during the process.

Overview: What is 5Z?

Genba or Gemba are Japanese terms meaning the real place. In a manufacturing organization, this may be referred to as the place where the work is done, or the value is added. Kanri is often defined as administration, control, or management.

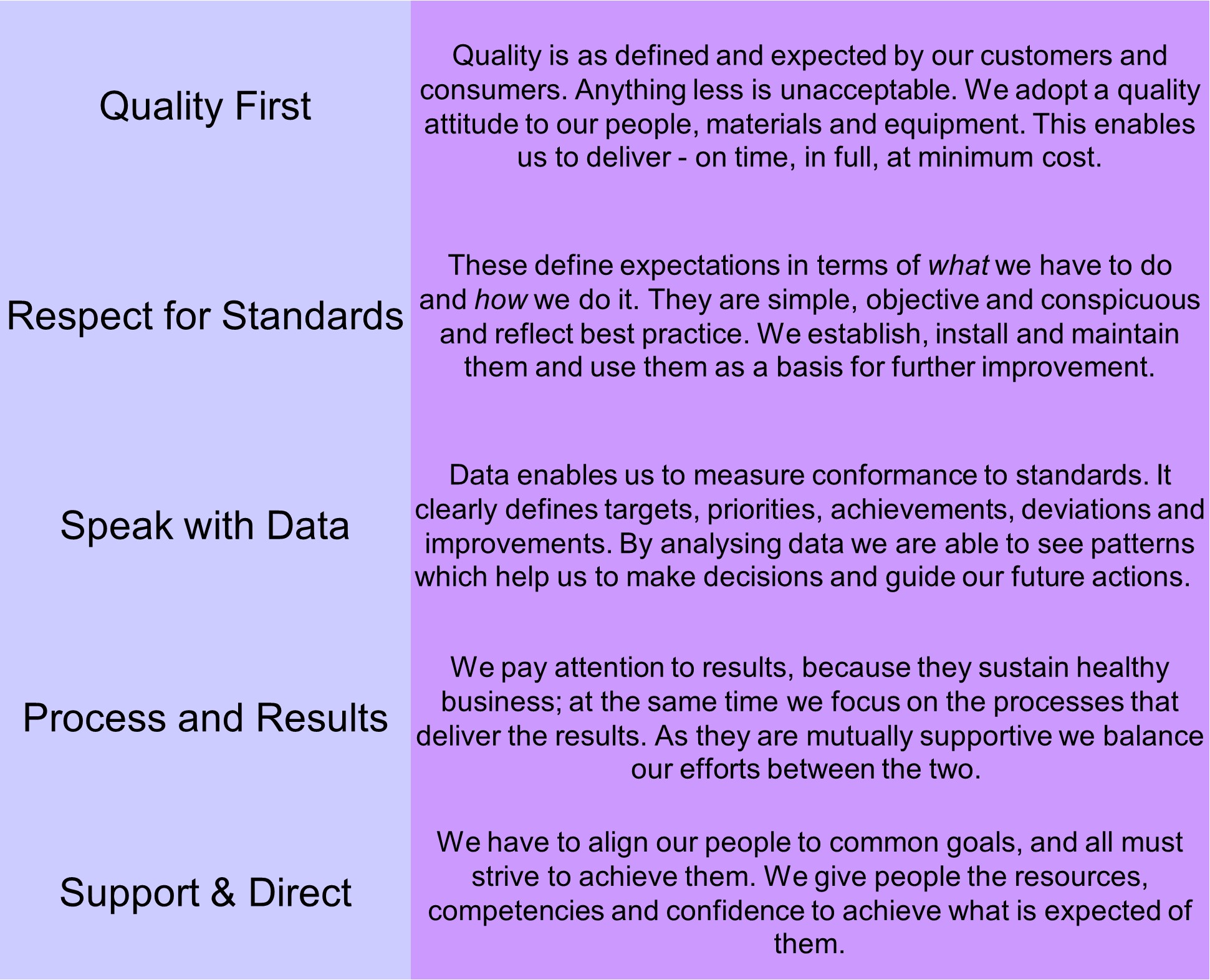

The principles of Genba Kanri are:

Basic Principles of Genba Kanri

Based on the above principles, the 5Z’s provide the following actions for error proofing and improving your process:

- Uketorazu – Don’t accept any defects

- Tsukurazu – Don’t make any defects

- Baratsukasazu – Don’t create any variation

- Kurikaesazu – Don’t repeat any mistakes

- Nagasaku – Don’t supply any defects

An industry example of 5Z

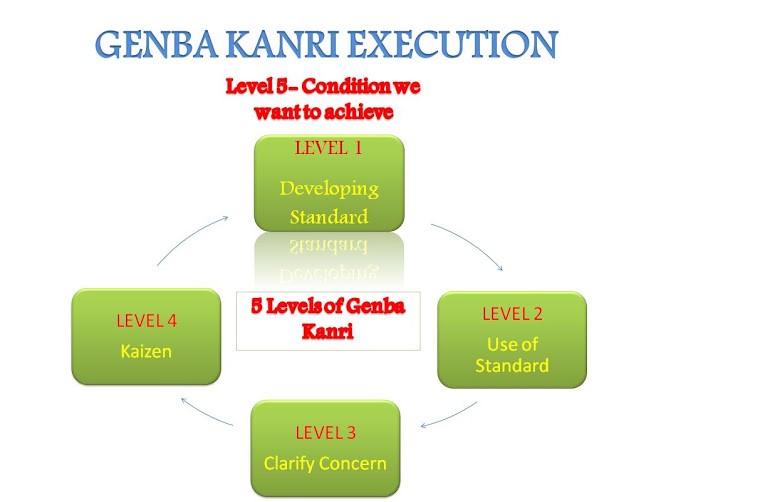

The Master Black Belt at an electronics manufacturer was given the responsibility of helping improve the processes in one area. She formed a team of equipment operators to implement the basics of Genba Kanri. Below is a graphic of what that is:

Since part defects were a major concern, when the team got to Level 4, they focused their Kaizens on the elimination of variation and defects by utilizing the basics of the 5Z actions. Those actions were:

- Uketorazu – Don’t accept any defects

- Tsukurazu – Don’t make any defects

- Baratsukasazu – Don’t create any variation

- Kurikaesazu – Don’t repeat any mistakes

- Nagasaku – Don’t supply any defects

After three months of working on the elimination of defects, the team was able to reduce their baseline defect rate of 3.5% to only .98%. This resulted in an annual financial benefit of over $3,400,00.

Frequently Asked Questions (FAQ) about 5Z

What are the benefits of using Genba Kanri?

Improved quality, reduced costs, lower inventory, and shorter lead times.

What is the purpose of the 5Z steps?

The goal of the 5Z steps is to eliminate any defects and errors that might occur during the process that will prevent the organization from optimizing its performance.

Is 5Z a common Lean tool?

No. An internet search will reveal very little information about 5Z. But, it is often referred to in the context of Genba Kanri which is a widely recognized approach to improving your organization with Lean Six Sigma.