Category: Lean

What is Lean Six Sigma Training and Certification?

Published:There are two steps to earn a martial arts belt. First, you must be trained in the various techniques and then you must demonstrate your skills and knowledge. The same holds true for Lean Six Sigma training and certification. Let’s learn a little more. What is Lean Six Sigma training and certification? In martial arts, […]

Read more »

How Can I Get Lean Six Sigma Trained and Certified?

Published:When there are too many items on a menu you can get confused by the variety of choices. Getting Lean Six Sigma trained and certified can also be confusing. Let’s discuss some of your options.

Read more »

Using Kanban to Streamline Processes and Improve Efficiency

Updated:Kanban is a tool used in Lean Manufacturing to visually manage the workflow through your processes. It is based on the concept of a pull system where things are only replaced as they are consumed.

Read more »

Failure Fuels Better Results from Lean

Published:Most Lean initiatives fail. What can you do about that? Ensure your organization’s leaders are champions for the deployment who encourage failure as part of your Lean journey.

Read more »

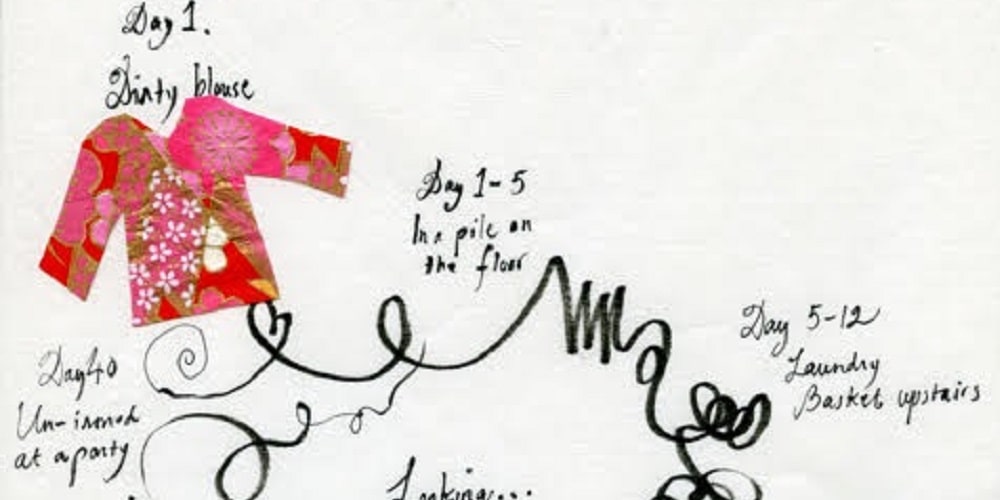

Apply Lean to Save the Planet and Your Marriage

Published:You’ve used Lean principles at work, but can it also work at home? One family implemented Lean in their daily lives over the course of a year with sustainable and measurable results. You can do it, too.

Read more »

How to Apply Lean in Construction

Published:If you work in construction, Lean will work for you. Answer 10 questions to find out if you need Lean, learn five ways to begin Lean, and be sure you know the ONE thing that MUST happen before beginning a Lean deployment.

Read more »

Lean Tools for the Novice

Published:Not an expert in Lean? No problem! Learn a few simple tools you can use in any setting, and help your organization save time and money.

Read more »

Lean Manufacturing: Improving Quality and Reducing Costs

Updated:Lean manufacturing seeks to get rid of the extra fat and waste in your process while seeking to build muscle in your production processes. Let’s see how.

Read more »

Introducing Agile Sigma

Updated:When it comes to selecting the “right” business process improvement methodology, many CEOs, CIOs and COOs have a wide array of options available including Six Sigma, Lean, Lean Six Sigma and ISO9000. The selection process then typically focuses on evaluating business drivers and deciding on an improvement methodology that closely matches their needs to improve […]

Read more »

Resource Page: Takt Time

Published:During the month of August – while many are taking time off to enjoy summer – we will be offering a resource page on a different topic each week. The resource page features an overview of the week’s topic and links to the best related content across iSixSigma. This week’s topic is takt time. What […]

Read more »

Tri-State Industries Grows with Lean Manufacturing

Published:Tri-State Industries was founded by Don Keller in 1980 as a manufacturer of industrial pipe guides and slides. In the 1990s, the company adopted the principles and practices of Lean manufacturing. Since its founding, Tri-State has grown to three product lines with a fourth in process. Along with pipe guides, Tri-State is a manufacturer of […]

Read more »

Lean Start-up: A Cycle of Continuous Evolution

Published:In the movement known as Lean start-up, a new enterprise starts with an idea about what customers want, not an idea for a product. Quick iterations that incorporate learnings from customer conversations with each iteration, rather than elaborate up-front product planning, lead a business to success.

Read more »

Lean Implementation for IT Company

Published:An information technology (IT) services company was engaged by a European telecom service provider to provide end-to-end testing for its five lines of business. End-to-end testing is a methodology used to test whether the flow of a software application is functioning as expected from start to finish – for example, from receipt of customer order […]

Read more »Solving Decreasing Sales With Lean Six Sigma

Published:Online retailer ABC sells books, DVDs, CDs, MP3 downloads, software, video games, apparel, furniture, food, toys and jewelry. ABC has a strong market research unit and a seamless feedback loop for enhancing the customer experience. In the last few years, however, sales had dropped significantly contributing to a slip in the overall market share of […]

Read more »

Lean Manufacturing Is a Form of Ethics

Published:According to Merriam-Webster, ethics is the discipline of dealing with good and bad. If you look beyond the tools and the jargon of the Toyota Production System (TPS), this is exactly what you will find; TPS is a system for defining good and bad, and right and wrong in a production environment. When we understand […]

Read more »

Applying Lean to New Product Development in Engineering Services

Published:Lean can be applied to any industry, not just manufacturing, because any business can benefit from improvements in cycle time, cost savings, productivity, efficiency and more. This case study examines the application of Lean to the engineering services industry in the areas of design, analysis and prototyping of parts to realize improvements in a subprocess […]

Read more »

Managing to Standard Work in the Office

Published:In the fourth quarter of 2010, Fairbanks Morse Engine had to swallow a tough message from its customers: You are too slow and we are not going to take it anymore! After an extensive voice of the customer (VOC) effort, it was clear that our lead times for aftermarket parts were missing customers’ expectations. Although […]

Read more »

FLEXcon: Lean for the Long Run

Published:The following are selected highlights of a corporate leadership profile of FLEXcon. The complete article – with more details about Lean application and how the company avoided layoffs during the recession – is available for purchase on the iSixSigma Marketplace. FLEXcon positions itself for growth by embracing Lean at every level More than 50 years […]

Read more »

Lean Increases Small Team Effectiveness Three-fold [VIDEO] – With Jim Benson

Published:Implementing the Lean methodology in small teams can have enormous benefit, in one case increasing team effectiveness, as measured by throughput, by 200 percent to 300 percent. Other benefits include better communication (both internally and to the entire organization), improved employee moral, improved work output and increased customer satisfaction. Jim Benson describes how, through the […]

Read more »

Gemba Walks Come to Life at Fairbanks Morse Engine

Published:Editor’s note: In a previous article, author Lindquist describes what a gemba walk is. Here he presents three examples of gemba walks. Gemba walks at Fairbanks Morse Engine demonstrate the importance of the sometimes-overlooked basics of process improvement. Case Study One Single Process – Pama Machining Center Observation: The objective of a series of events […]

Read more »

The Many Sides of a Gemba Walk

Published:Editor’s note: A follow-up article features three specific examples of gemba walks. With so many tools available to a continuous improvement professional, it is easy to get overwhelmed and consequently focus on a narrow grouping of tools. Experience expands the practitioner’s toolbox, but sometimes it is just as important to return to the foundations to […]

Read more »

A Case of Mistaken Capability

Published:Lean Six Sigma (LSS) teams focus on the statistical analysis of metrics when identifying opportunities for improvement. The strong focus on data-driven evaluation, however, can overshadow the human element that exists behind the data collection plan. Despite its importance, the impact of human interaction is not easily visible or quantified, buried under reams of data. […]

Read more »

Increase Lean Six Sigma’s Power with TOC and Systems Thinking

Published:In order to achieve maximum and consistent returns with Lean Six Sigma, combine LSS with systems thinking and TOC into a single continuous improvement approach.

Read more »

Beware of Tools and 'The Next Big Thing'

Published:Isn’t it amazing how there’s “the next big thing” everyday? Headlines from blogs, sales websites, newspapers, even Twitter and LinkedIn, carry this headline continuously. How many of these “things” really are new? Years ago when I started my continuous improvement journey, I read about Deming and Juran. Quality Circles and SPC were big. Then Total […]

Read more »