Category: DMAIC

What Is DMAIC?: Master Your Process Improvement

Published:DMAIC refers to a data-driven quality strategy for improving processes, and is an integral part of the company’s Six Sigma Quality Initiative. DMAIC is an acronym for five interconnected phases: Define, Measure, Analyze, Improve, and Control.

Read more »

A Comprehensive Guide to Input-Process-Output Models

Published:Creating and mapping business process models can sound like a daunting task with little tangible value. With input-process-output models, we debunk these myths and introduce a versatile, straightforward methodology that can be used to transform your business.

Read more »

Insights from COPIS for Improved Efficiency

Published:What does your process look like from 30,000 feet? Your extended process view can be described using COPIS, or customer, output, process, input, and supplier. Let’s get in our balloon and go up.

Read more »

The 10 Questions of DMAIC: Process Improvement Done Right

Published:Use these 10 questions when teaching DMAIC. Learn when and where some commonly used Six Sigma tools do – or don’t – apply; align the tools to the underlying question as part of this coaching task.

Read more »

Y = f(x) Roadmap: Telling the DMAIC Story Using Xs and Ys

Published:With its DMAIC (Define, Measure, Analyze, Improve, Control) roadmap, the Six Sigma methodology provides a structured and systematic approach to solving business and process problems. The related toolkit is a selection of proven tools and methods that– correctly applied – help to determine, analyze, and improve a problem. All is well and good, however, […]

Read more »

Six Sigma DMAIC Roadmap: Get Your Processes Under Control

Published:The Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) methodology can be thought of as a roadmap for problem-solving and product/process improvement. Most companies begin implementing Six Sigma using the DMAIC methodology and later add the DFSS (Design for Six Sigma, also known as DMADV or IDDOV) methodologies when the organizational culture and […]

Read more »

PDCA vs. DMAIC: What’s the Difference?

Published:What are the differences between PDCA and DMAIC? There is no shortage of jargon and acronyms to keep track of within the Six Sigma methodology. However, the two methods we’re looking at today blur the lines substantially. So, let’s jump in and see exactly how these approaches differentiate themselves. What is PDCA? Plan […]

Read more »

Understanding Six Sigma: Definition, Benefits, and Best Practices

Updated:Six Sigma has been defined in three ways: as a metric, a methodology, and a philosophy. Sigma can be defined as the standard deviation of a set of continuous data, so Six Sigma would then be six standard deviations.

Read more »

Mastering Process Improvement Through Y=f(x) Methodology

Published:Y=f(x) is a concept regarding the setup of a formula used to perform analysis during problem-solving efforts. Let’s look at how Y=F(x) works within the problem-solving process, the benefits of Y=F(x), as well as some frequently asked questions.

Read more »

Design For Six Sigma (DFSS) vs. DMAIC: What’s the Difference?

Published:One of the most confusing issues associated with someone saying “I’m using Six Sigma” has to do with what methodology they are using. A majority of the time they are using the DMAIC methodology because they have existing processes that are wasting resources (hence the big savings you’ve heard about at GE, Honeywell, […]

Read more »

1.5 Sigma Process Shift: What It Means For Your Business

Updated:Why is 6 sigma 3.4 ppm, not 2 ppb? The calculation of process sigma after a process improvement project should be reported as short-term sigma.

Read more »

Lean Six Sigma Transformation: Harnessing DMAIC to Enhance Operational Efficiency and Customer Satisfaction at Avon

Updated:Efficiency, Elegance, and Empowerment: Avon and Lean Six Sigma Unite In the bustling world of cosmetics, where beauty meets business, one name has stood the test of time, captivating hearts and empowering women for over a century: Avon. From its humble beginnings as a perfume company in the late 19th century to its global presence […]

Read more »

How Dr Pepper Embraced Lean and Six Sigma Methods, Creating an Economic Impact of Over 100 Million Dollars for the Company

Published:By employing Lean and Six Sigma techniques, Dr Pepper was able to embark on a journey that prioritized Rapid Continuous Improvement, a strategy that led to a number of savings for the organization that totaled over 100 million dollars. Dr Pepper Had a Problem Dr Pepper’s history traces all the way back to 1885 and […]

Read more »

How Lean Six Sigma Tools and an Acceleration Technique Reduced Baggage Connection Delays by 65%

Updated:In 2016, Kenya Airways embarked on a project to increase its baggage handling efficiency. The way that it applied tools from both Lean and Six Sigma methodologies showcases how adaptable these concepts can be and that they are applicable well beyond the industries that they are most commonly associated with. Kenya Airways was able to […]

Read more »

Six Sigma vs. Agile: What Are the Differences?

Updated:What is Six Sigma? Six Sigma is a disciplined, data-driven approach and methodology used by organizations to improve their processes and reduce defects or errors. It was originally developed by Motorola in the 1980s and has since been adopted by numerous companies across various industries. The term “Six Sigma” refers to a statistical concept that […]

Read more »

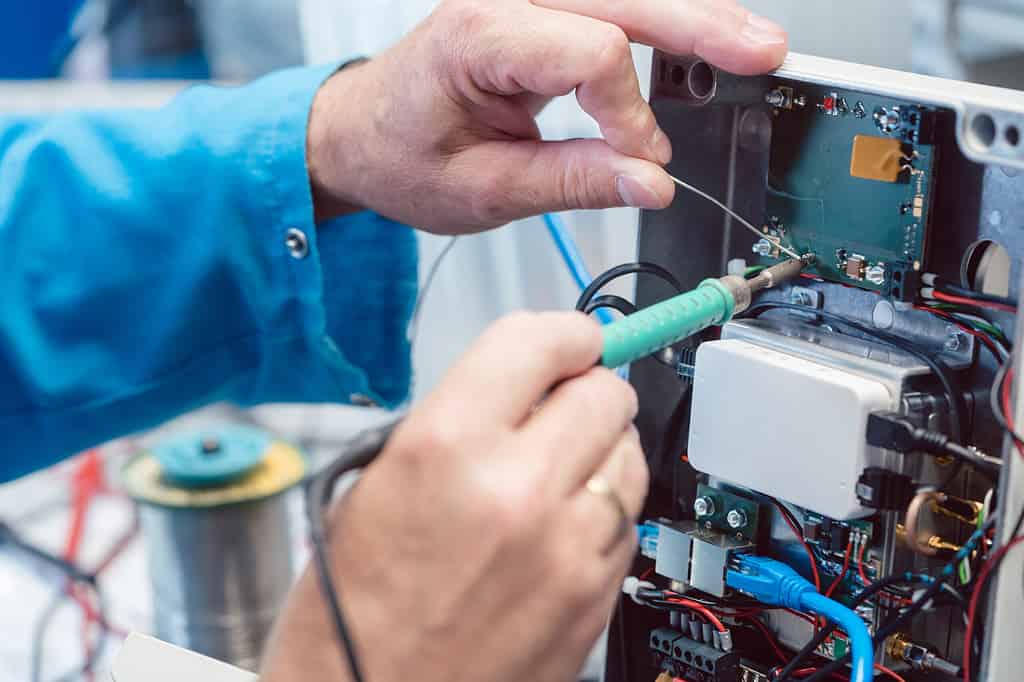

Kienle + Spiess Tackles Welding Issues with Lean and Six Sigma Integration

Updated:Kienle + Spiess is a German mechanical engineering company that was looking to strengthen its welding division by reducing its rework and improving its quality. To accomplish this, the organization utilized a dual approach where Six Sigma and Lean methods work in tandem. Kienle + Spiess was able to practically eliminate shoddy splatter from the […]

Read more »

Six Sigma vs. Lean: What’s the Difference?

Updated:What is Six Sigma? Six Sigma is a quality control methodology that is utilized to improve processes through the elimination of defects. In practice, the methodology incorporates project management, analysis, and statistics to improve the functionality of a business by addressing defects in a process. The cornerstone of the Six Sigma method is the DMAIC […]

Read more »

How DMAIC Helped San Antonio Increase the On-Time Payment of Street Maintenance Contractors by Nearly 20%

Published:We all need payment for the work that we do. It is really that simple. If contracted out to do a job by somebody, you need to be able to count on compensation for the work done on that job within a reasonable amount of time. Contractors that worked on street maintenance projects for the […]

Read more »

How the Six Sigma Quality Improvement Process Practically Eliminated False Fire Alarms at US West

Published:In the early 1990s, US West was an organization that was leading the charge in telecommunications. At the time, their buildings were being plagued by disruptive false fire alarms. How it was dealt with is a great example of how to apply the Six Sigma quality improvement process, a method applicable to nearly any quality […]

Read more »

How DMAIC Led to a Nearly $950,000 Impact on RFR’s Bottom Line

Updated:Utilizing Six Sigma tools like DMAIC saved RFR $928,000 in retained sales as well as $10,000 in cost savings and $9,000 in workplace training. RFR Metal Fabrication Was Having Growing Pains RFR Metal Fabrication began as Advanced Fabrication Technology in 1987, switching names to RFR in 1999. Throughout its history, the organization has focused on […]

Read more »

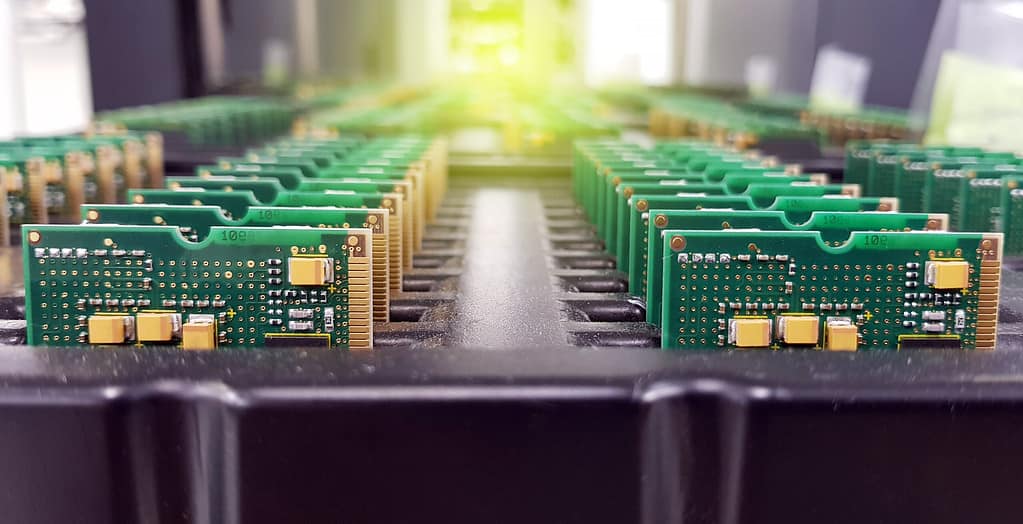

Littelfuse’s Journey to Operational Excellence: How Six Sigma Processes Improved Quality and Reduced Costs

Updated:Littelfuse is a manufacturing company that produces electronic products for various industries. The company was facing a problem with its production process, as it was experiencing a high defect rate that was causing delays and increasing costs. Products were experiencing defects and failures, which resulted in customer complaints, rework, and repairs. These quality issues were […]

Read more »

How DMAIC and Other Six Sigma Techniques and Tools Helped B & B Ice and Water Save $21,000 on Their First Six Sigma Project

Updated:B & B Ice and Water in Port Arthur, Texas, had been a successful company for many years. Despite their success, the organization was finding a number of problems that they could not seem to solve. By embracing Six Sigma techniques, the organization was able to address these issues, make its company stronger than before, […]

Read more »

Motorola Uses Data-Driven Six Sigma Methodology to Improve Production Process

Updated:In the early 2000s, Motorola struggled with product defects and a decline in customer satisfaction. To improve its business processes and regain its competitive edge, Motorola turned to Six Sigma. This data-driven methodology for process improvement turned their fortunes around. The Impact of Six Sigma on Motorola’s Semiconductor Production Process Motorola is a multinational telecommunications […]

Read more »

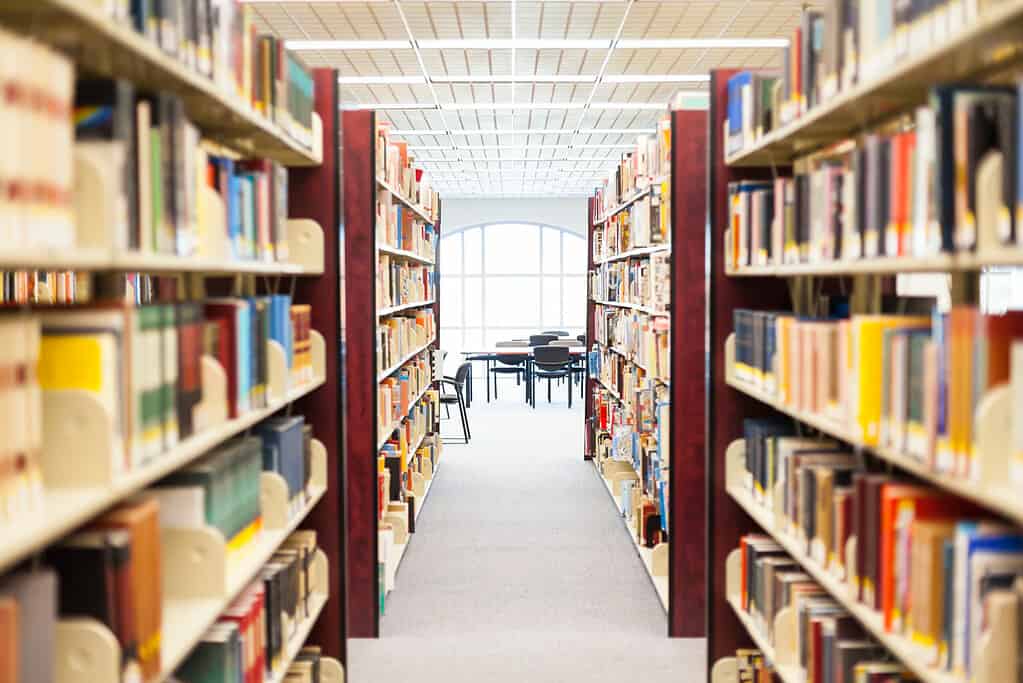

DMAIC Helps Miami-Dade Public Library Improve Services and Save Money

Updated:In 2018, the Miami-Dade Public Library System utilized Six Sigma methodology to improve upon the time needed for the transporting of library materials. The utilization of Six Sigma to meet the needs of this type of organization is an exciting example of just how versatile these tools can be. When we go to the library, […]

Read more »