Category: Concepts

Voice of the Business: Benefits and Uses for Your Organization

Updated:Do you hear voices? In a business context, that’s normal. Let’s listen in to the voice of the business and hear what it has to say.

Read more »

Out of Control Action Plan: Correcting Process Variants for Optimal Performance

Updated:Out-of-control Action Plans (OCAPS) are a piece of the Lean Six Sigma methodology that is often overlooked. Though they have been phased out in some organizations, it is important to understand their purpose and how they can help a company improve its processes.

Read more »

What You Need to Know to Calculate CP and Interpret Its Value

Updated:Cp is one of the metrics calculated for determining whether your process is capable of meeting customer specifications or requirements. It is useful in comparing different functions and their ability to meet their unique specifications.

Read more »

Revolutionizing Organizational Change with the CAP Approach

Updated:Do you feel that implementing change in your organization is going too slowly? So did Jack Welch of GE, which is why GE developed the Change Acceleration Process (CAP). Let’s explore how the concepts of CAP might help your organization.

Read more »

B10 Life: Engineering Products for Reliability

Published:As competitive and market pressures increase, having a clear understanding of product reliability, service life, and expected failure rate is crucial. We explore how by utilising B10 life, we can optimise our product development and satisfy our customer requirements.

Read more »

Mastering the Basics: The Fundamentals of Statistics and Inference

Updated:Statistics is a branch of math that involves the collection, description, analysis, and inference of conclusions from quantitative data. But what is a statistic? Let’s find out. The word statistic is a word with numerous possible definitions. In its simplest form, a statistic can be defined as a descriptor of a set of data. The […]

Read more »

Understanding Exponentially Weighted Moving Average for Time Series Analysis

Updated:Does your data from yesterday represent the current state of your process better than that from a month ago? How can you place more emphasis on it yet still make use of older data? That’s what the Exponentially Weighted Moving Average does.

Read more »

How House of Quality Shapes Product Excellence: Meet Your Customer’s Needs

Updated:House of Quality? No, this is often referred to as a House of Pain because of the effort needed to complete one. Let’s see if we are just being overly pessimistic.

Read more »

Driving Quality Improvement with DPMO: A Roadmap to Process Excellence

Updated:Lean Six Sigma professionals, much like every other professional, love to talk in acronyms. The acronym of the day is DPMO. Let’s check out what it means.

Read more »

Defects per Opportunity (DPO): Get Context for the Flaws in Your Processes

Updated:Defects per opportunity, or DPO, refers to the number of defects that occur in relation to a given number of opportunities for which an error could occur. Let’s consider some of the benefits of measuring and monitoring DPO.

Read more »

Rolled Throughput Yield (RTY): Make Sure Your Production Is Making the Grade

Updated:What is rolled throughput yield? Your company has just announced that its product line has a 100% total throughput rate, touting it as a great win for everyone. However, from your perspective, you see massive amounts of rework being performed, disrupting the production lines, costing additional money, and impacting on-time delivery. If only there was […]

Read more »

How to Use Voice of the Customer to Improve Customer Experience

Updated:An organization may hear many voices (Customer, Business, Employee, and Process). It is the voice of the customer (VOC) that is the driving voice. Additionally, it is what should be important to the organization and what the organization should focus on. The satisfaction of the VOC needs to be balanced against the Voice of the […]

Read more »

How ZARA Revolutionized the Fashion Industry with Lean Practices

Published:ZARA changes its clothing designs every two weeks, offering 11,000 distinct garments annually. In comparison, competitors change their designs every three or four months and produce 3-4,000 distinct pieces. This is fast fashion: the business model of replicating high-fashion, luxury-brand pieces quickly and cheaply, making them available to customers while the trend and […]

Read more »

Navigating Data Analysis: The Importance of Testing for Normality

Updated:Is your data normal? Oh no! Is that a problem? The concept of data normality can be important when using certain statistical tools to make data-driven decisions.

Read more »

Understanding the Formula and Benefits of Cycle Time

Updated:The customer just called again, wondering if the item they ordered will be on time. Will it? Do your company’s processes make it possible to be on time per the customer’s needs? To know that requires understanding how long it takes to produce the product, and that requires knowing your cycle times. An Overview: What […]

Read more »

Pugh Matrix: Learn How This Tool Empowers Your Decision-Making Process

Updated:You are often faced with many options on how to improve the process. Which one is the best? The Pugh Matrix is a simple tool for you to decide which approach — or hybrid of approaches — you should use.

Read more »

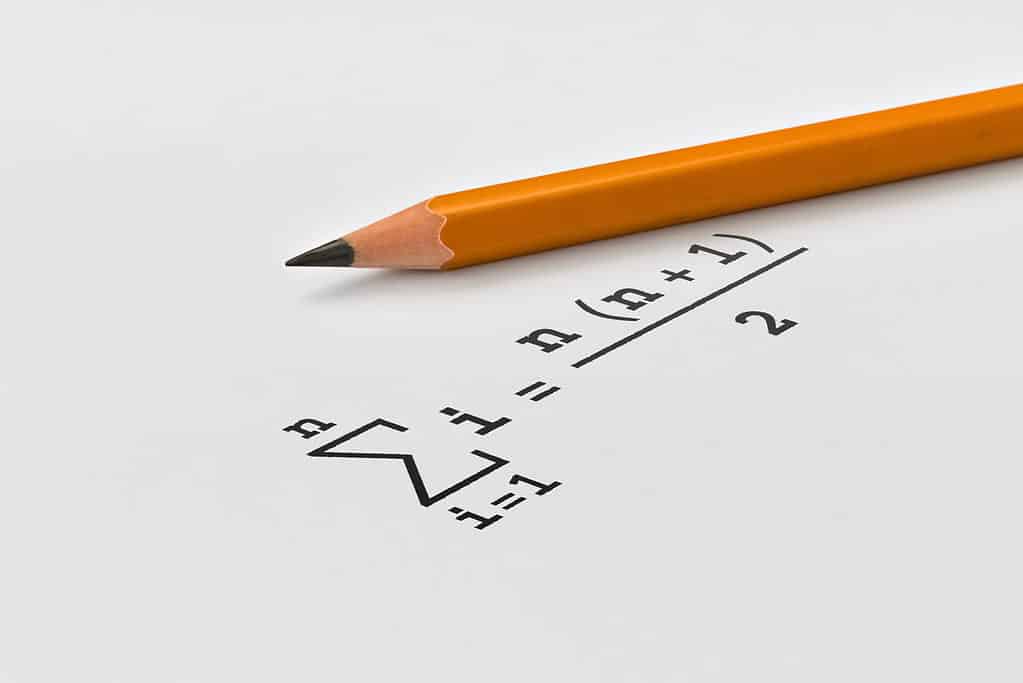

Sigma in Statistical Analysis: What You Need to Know

Updated:Sigma is the eighteenth letter of the Greek alphabet and is used as a common notation in statistics as a measure of summation and variation.

Read more »

Sigma Level: Striving for Perfection in Your Production

Published:Learn the benefits of tracking sigma level, including how it is used to understand how the current quality capabilities match with customer expectations, where future process improvement opportunities lie, and how to verify results.

Read more »

The 8 Wastes of Lean: Understanding and Addressing Them in Your Organization

Updated:Waste is all around your organization. Using TIMWOODS and DOWNTIME, you will learn how to identify the 8 Wastes of Lean and eliminate it to improve your organization.

Read more »

How Lean Six Sigma Practices Helped Amazon Web Services Achieve Operational Excellence

Updated:In today’s highly competitive business landscape, organizations are constantly seeking ways to improve their operations and deliver exceptional value to their customers. One such company that embarked on a transformative journey is Amazon Web Services (AWS), the cloud computing arm of Amazon. Facing significant challenges, AWS turned to Lean Six Sigma practices and tools to […]

Read more »

How Lean and Six Sigma Dramatically Improved InterConnect’s Kit Manufacturing Line

Updated:InterConnect Wiring was constantly needing to be ahead of schedule in assembling its aircraft kits, causing unneeded stress and an unbalanced workload. By utilizing Lean and Six Sigma concepts, the organization was able to make significant improvements to its processes. Despite already being a very successful organization, InterConnect Wiring was able to utilize Lean and […]

Read more »

Project Sponsor vs. Deployment Champion in Six Sigma: What’s the Difference?

Updated:What is a Project Sponsor? A Six Sigma project sponsor plays a key role in Six Sigma methodology who provides overall support, guidance, and resources to ensure the success of a Six Sigma project. The project sponsor is typically a high-level executive or manager within the organization who has the authority to allocate resources and […]

Read more »

Black Belt vs. Master Black Belt in Six Sigma: What’s the Difference?

Published:What is a Black Belt (BB)? A Six Sigma Black Belt (BB) is a trained and certified professional who has achieved a high level of expertise and experience in the Six Sigma methodology. Six Sigma is a data-driven methodology and management philosophy that aims to improve the quality of processes, reduce defects, and minimize variability […]

Read more »

How Lean Six Sigma Tools and an Acceleration Technique Reduced Baggage Connection Delays by 65%

Updated:In 2016, Kenya Airways embarked on a project to increase its baggage handling efficiency. The way that it applied tools from both Lean and Six Sigma methodologies showcases how adaptable these concepts can be and that they are applicable well beyond the industries that they are most commonly associated with. Kenya Airways was able to […]

Read more »