Category: Tools & Techniques

Alternatives to Value Stream Mapping That Can Be Effective

Published:Value Stream Mapping (VSM): An Overview Value Stream Mapping (VSM) is a Lean management tool used to visualize, analyze, and optimize the flow of materials and information required to deliver a product or service to customers. It helps identify inefficiencies, bottlenecks, and waste in the process, enabling teams to improve value delivery and […]

Read more »

Overcoming Common Challenges in Digital Transformation

Published:What are the most common challenges in digital transformation? Digital transformation is one of the driving forces behind modern business. However, making the most of the digital revolution isn’t always a sure thing. As such, it takes a somewhat deft hand to navigate the common pitfalls of digitizing your workplace. This can result […]

Read more »

Streamlining Six Sigma Projects with the 7 QC Tools

Published:The seven basic tools in my home tool chest are a hammer, screwdriver, wrench, saw, drill, pliers, and duct tape. What basic QC tools do you have in your continuous improvement tool chest? Let’s check it out.

Read more »

Key Digital Tools Driving Business Agility

Published:What tools are needed to create business agility? An agile business can adapt and roll with the punches. I don’t mean a momentary setback but events that a business can easily adapt and overcome. In software development, this methodology is known as Agile and is one of the driving forces behind modern development […]

Read more »

Step-by-Step Guide to Conducting an FMEA

Published:What’s the best process for conducting an FMEA? If you want to start implementing lasting changes into your production line, FMEA is one of the top ways to get things rolling. However, there is a certain procedure you’ll want to follow to make the most of your efforts. If you’re new to the […]

Read more »

FMEA in Product Development: Reducing Risk Early On

Published:How can you use FMEA in product development? I’ve talked at length about using FMEA as a means of rectifying problems in production. However, you can apply the methodology to the design process of any product or service you’ve got in the works. It isn’t similar to DMAIC, as DMAIC is generally used […]

Read more »

Common Pitfalls in FMEA and How to Overcome Them

Published:What are the most common mistakes you can make with FMEA? As a framework, FMEA is aimed at creating lasting solutions to potential problems before they even arise. However, that doesn’t mean it’s completely foolproof. As we’ve seen with many of the tools of the trade, there is certainly a right and a […]

Read more »

Real-World Examples of FMEA in Action

Published:How does FMEA work in the real world? We often discuss concepts, methodologies, and frameworks in a vacuum. However, understanding the realistic applications of a useful and quality-driven framework like FMEA pays off in the end. So, with that in mind, let’s look at a few examples of how FMEA is implemented in […]

Read more »

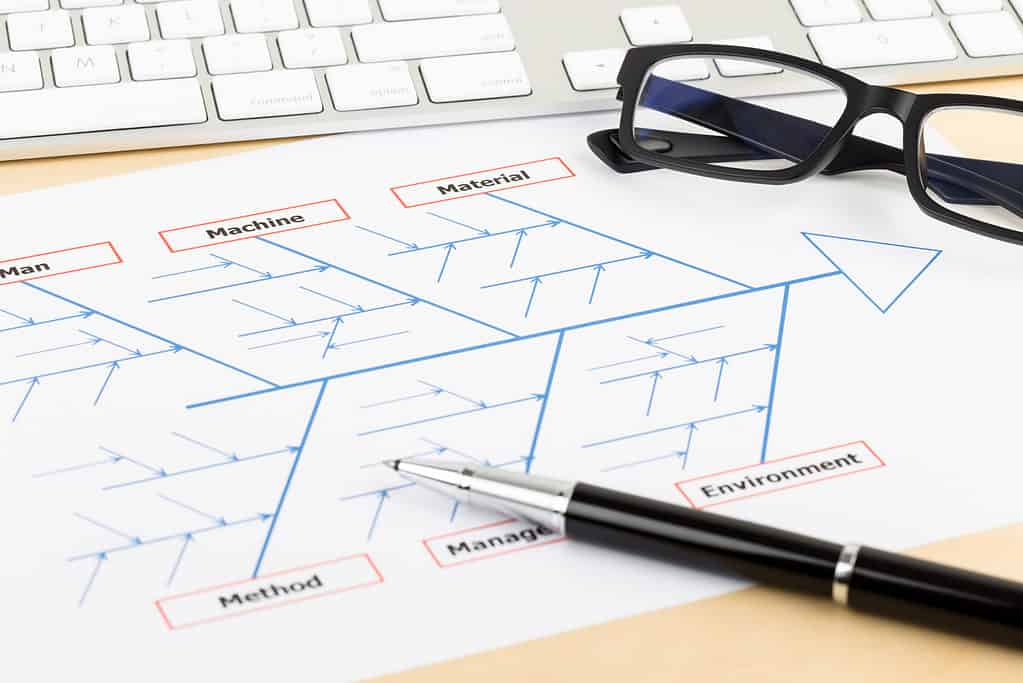

Mistakes When Using Fishbone (Ishikawa) Diagrams

Published:What mistakes are common when using Ishikawa diagrams? As one of the easiest tools to use in the Lean Six Sigma toolbox, there is a very real potential for misusing these diagrams. It isn’t necessarily a lack of knowledge that hinders these tools, but other common pitfalls that make them less effective than […]

Read more »

The Best Tools To Make a Fishbone (Ishikawa) Diagram

Published:What are your best resources for making a Fishbone diagram? You might not always have a pen and paper handy, and you might need something more readily presentable for leadership. So, what do you do? You’d likely turn to some of the many popular and powerful software packages available for visualization tools. With […]

Read more »

Fishbone Diagrams: How to Diagnose Process Problems

Updated:How do you use fishbone diagrams to get to the root of a problem? Fishbone diagrams are one of the 7 QC tools afforded to us by Lean Six Sigma and one of the most effective at determining issues. These are simple tools to use, meaning anyone in your team can leverage their […]

Read more »

While Calculating Pp and Ppk, How Do I Determine the Value of Short-Term and Long-Term Standard Deviation?

Updated:One must understand that the short-term standard deviation reports on a process’s “instantaneous reproducibility” whereas the long-term standard deviation reflects the “sustainable reproducibility.” To this end, the short-term standard deviation comprises the “within group” sums of squares (SSW). The long-term standard deviation incorporates the “total” sums-of-squares (SST). Of course, the difference between the two constitutes […]

Read more »

Predicting Success: A Comprehensive Guide to Trend Analysis Tools

Published:Do you possess a crystal ball to see what the future brings for your organization? Probably not, but you do have a statistical version of a crystal ball by using trend analysis.

Read more »

Achieving Excellence Through Quality Management

Updated:The strategy of continuously improving your organizational processes by setting your goals, identifying deviations from those goals, and then taking appropriate actions to adjust your processes to close the gaps.

Read more »

SCAMPER: Generating Creative Approaches to Process and Product Enhancement

Updated:SCAMPER is an acronym for a simple approach to creative brainstorming. The technique uses a series of questions that prompt you to come up with creative ideas for improving products and processes.

Read more »

Essential Strategies for Identifying Key Business Requirements

Updated:Key business requirements are everything. They are the measure by which your product, process or company lives or dies, so ignorance is not an option.

Read more »

From Problem to Solution: The Power of Gap Analysis

Updated:Keeping one step ahead of the competition whilst consistently meeting customer requirements makes a lot of business sense. Using gap analysis, we have a methodology that helps to understand and achieve full business potential whilst driving continuous improvement.

Read more »

Boosting Customer Satisfaction: The Advantages of a Centralized Performance Center

Updated:Does your organization have a centralized department or function that monitors and tracks the performance of your operations relative to your customers? If you do, let’s see what it might be doing. The term “Customer Operations Performance Center” is not a widely recognized or standardized term, so its exact meaning may vary depending on the […]

Read more »

The 5Ps: A Proven Method for Meeting Effectiveness

Updated:Ever been to a business meeting? Ever thought it was a waste of time? Let’s explore how the 5Ps of meeting effectiveness may help you have a better meeting.

Read more »

What should you do if your data isn't normal, even after a transformation?

Published:It is possible to analyze non-normal data when conducting a capability analysis – even if it cannot be transformed to a state of normality. Of course, this position assumes that the underlying distribution is unimodal in nature (i.e., not multimodal). Technical details aside, this particular type of problem can quickly become an analytical nightmare for […]

Read more »

In a Pareto chart, 20% of the causes represent 80% of the problem but there are never 20%…usually there are more. Why is this?

Published:The gentlemen referred to as “Pareto” long ago advocated that 80 percent of the world’s wealth was controlled by 20 percent of the world’s population. This phenomenon is also called the “Pareto Principle,” and will be designated as “PP” for our discussion. For the case just given, it should be noted that the 80 percent […]

Read more »

If you are only allowed to select a handful of tools in the six sigma tool box, what are the tools you will select as the key ones?

Published:It is now late in the evening as I prepare an answer to your question. Maybe it’s the fatigue after a day of providing answers or perhaps it’s the nature of the question, but what really grabs me about your question (perhaps in the wrong way) is the word “tools.” From a different perspective, I […]

Read more »

What do you do in automated manufacturing environments, hospitals, telecom centers or data centers where equipment uptime is so critical?

Published:Based on the elements of your question, I would say that your problem could be readily shaped into a Black Belt project. I would assume that a Pareto analysis has already been conducted. As a more advanced diagnostic, you should consider employing a multi-vari chart. Although simple in nature, such a chart has considerable power. […]

Read more »

Could you explain the best way to predict the outcome of a process in the future?

Published:Reference the quality literature on statistical process control, also known as “SPC.” There are many excellent books on the subject, particularly the one by “Grant and Levenworth.” Process improvement and optimization is often accomplished by way of statistically designed experiments, or “DOE” as it is known. To this end, the work of “George Box” is […]

Read more »