Category: 5 Whys

Getting to the Bottom of Your Problem: How to Use the 5 Whys

Published:Asking “Why?” may be a favorite technique of your 3-year-old child in driving you crazy, but it could teach you a valuable Six Sigma quality lesson. The 5 Whys is a technique used in the Analyze phase of the Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) methodology. It is a great Six Sigma tool that […]

Read more »

Gemba: The Key to Engaging Employees and Improving Performance

Published:Does Going to Gemba sound like a nice trip to an exotic locale? While not a fancy foreign destination, Gemba is going to where the work is done to learn more about the process. Let’s take a deeper look into what Gemba is about.

Read more »

The Difference Between Correction and Corrective Action in Business Problem-Solving

Published:Problems are going to arise in business, but the companies that succeed in the long term are those that find the true causes of those problems and find ways to keep them from happening again. When an issue occurs, the inclination is to stop it quickly. While this is fine, it is important […]

Read more »

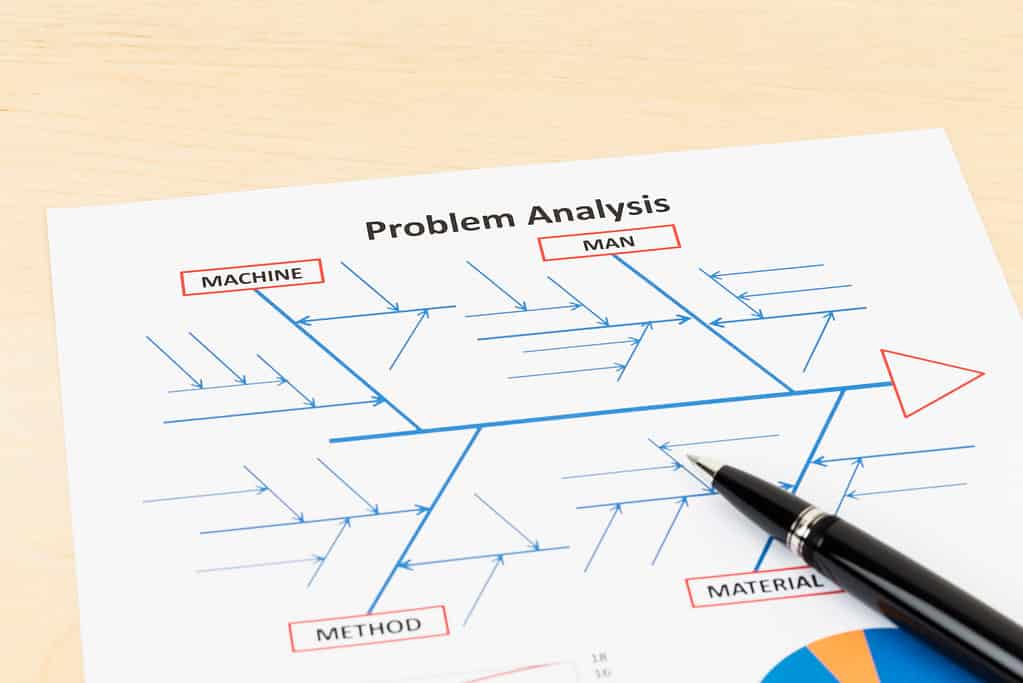

Root Cause Analysis: Integrating Ishikawa Diagrams and the 5 Whys

Updated:Root cause analysis (RCA) is a way of identifying the underlying source of a process or product failure. As such, then the right solution can be identified. RCA can progress more quickly and effectively by pairing an Ishikawa diagram. You can also use the scientific method in the form of the well-known plan-do-check-act (PDCA) cycle […]

Read more »

How Value Stream Mapping Helped Increase a University’s MBA Enrollment by 70%

Updated:The University of North Alabama had been part of the steady decline nationally in students enrolling in MBA programs. In order to turn the tide at the UNA College of Business, a team utilized Value Stream Mapping. By focusing on adding value to the student recruiting process, UNA College of Business was able to dramatically […]

Read more »

How One Company’s Investment in Employees Led to $40K in Savings

Updated:In business, when times get tough, the knee-jerk reaction is to have layoffs. What follows is a remarkable example of one company that decided to make a further investment in its people by getting them trained toward Six Sigma Green Belt certification and having them put their focus on saving money for the organization. Even […]

Read more »

How Six Sigma and Lean Tools Helped Recover Nearly 4 Million Dollars in Annual Revenue

Updated:When faced with the news that drug manufacturers of cancer medication were responsible for causing a massive amount of financial waste, the oncology department at UCSD utilized Six Sigma and Lean tools like a cause-and-effect diagram, a Kaizen Event, the 5 Whys, and others in order to improve scanning processes that could help in recovering […]

Read more »

How Six Sigma Tools Sharply Decreased Downtime At The Nature Conservancy’s Headquarters

Updated:The web development team at The Nature Conservancy in Arlington, VA, was able to utilize Lean and Six Sigma tools to close the gap in downtime due to a coding freeze every 45 days. The Nature Conservancy used such Six Sigma tools as process maps, The 5 Whys, and cause-and-effect diagrams to dramatically bring the […]

Read more »

Understanding Corrective and Preventive Action: A Systematic Approach to Problem-Solving

Updated:Often organizations do a root cause analysis after a problem has occurred. Is there something you can do as a preventive action prior to something happening. Let’s learn more about CAPA. Corrective and Preventive Action (CAPA) is a systematic approach used in various industries, including manufacturing, healthcare, and quality management, to identify and address the […]

Read more »

The Simple Yet Powerful 5 Whys Method for Effective Problem-Solving

Updated:Asking the 5 Whys is a quick way to get to the root cause of a problem your organization may be dealing with.

Read more »

Case Study: Using the 5 Whys to Validate Assumptions

Published:The effectiveness of any process improvement tool depends on the process improvement practitioners’ assessment of the situation, choice of the simplest tool and the creative use of the tool. This article provides an example of how a simple tool, the 5 Whys, was used to unearth an assumption embedded in a business process. Once the […]

Read more »

Resource Page: The Whys and Wherefores of the 5 Whys

Published:As parents of young children know, “Why?” is one of the most frequently asked questions they hear. And not just once. A girl asks, “Why is the sky blue?” and will proceed with further “Why?” demands to each subsequent answer for as long as the parent is willing (or able) to play along. As frustrating […]

Read more »

Reducing Misdirected Calls in Automated Payment Systems

Published:While working on a maintenance project for a large U.S. telecommunications firm, information technology company Infosys Technologies Ltd. discovered that an unacceptably high percentage of calls in the clients’ automated payment system were being routed to the call center agents. The team conducted a DMAIC project, outlined here, to reduce the number of misdirected calls. […]

Read more »

Medical Transcription Six Sigma Case Study

Published:Today’s industrial black belt typically trains for six months. Seventy-five percent of this training time is spent learning theory, and the balance is spent in practice. Often when the black belt returns to the real world to tackle inefficiencies, he finds that there are no takers for his logic and passion – his Six Sigma entreaties fall on […]

Read more »

Newspaper Aims to Improve Printing: A TQM Case Study

Published:Caught in an exploding market, with rapidly improving products, the management of a media organization in India realized that improving the quality of printing of its newspaper was imperative to survival and progress. The organization adopted total quality management (TQM) and has completed several improvements in office processes related to turnaround, which is so vital […]

Read more »

5 Lean Tools and Principles to Integrate into Six Sigma

Published:Increasingly, organizations that use Six Sigma are making an effort to integrate Lean into their existing process-improvement framework. For many, combining Six Sigma’s focus on process quality and Lean’s emphasis on turn-around time results in more high-impact, quick-hit projects. To gain this advantage, however, organizations must face a difficult obstacle: integrating Lean without creating ripples […]

Read more »

Final Solution Via Root Cause Analysis (with a Template)

Published:“Every defect is a treasure, if the company can uncover its cause and work to prevent it across the corporation.” – Kilchiro Toyoda, founder of Toyota When people discover problems, the most frequent response is to rush to find a solution. Finding an immediate fix for the problem is very satisfying no matter how many […]

Read more »

Going Beyond the 5 Whys

Published:“So what?” That’s all your CEO has to say after you present your latest Lean Six Sigma triumph. You gaze out over a deafeningly silent boardroom. Your team is stunned. While you try to comprehend the CEO’s demoralizing response, the other managers and administrators chime in: “Yeah, so what?” The above scenario might be an […]

Read more »

Reveal Assumptions and Find Root Causes with Webbing

Published:Six Sigma practitioners looking to clarify or explore a task, find root causes of a problem or develop their strategic thinking skills may want to consider using webbing, a valuable exploration tool. Similar to the 5 Whys, this tool encourages practitioners to ask a web of questions about a task or process in order to […]

Read more »

TQM Case Study: Newspaper Focuses on Customer Service

Published:Quality in the total quality management (TQM) method is defined as customer delight. Customers are delighted when their needs are met or exceeded. The needs of the customer are: Product quality Delivery quality Service quality Cost value Improving customer service was the focus of two projects within the deployment of TQM in a mid-sized newspaper […]

Read more »

The 5 Whys: A Simple Tool in Value Stream Analysis

Published:Not so long ago in an organization not so far away, a Lean Six Sigma Black Belt not much different from many other Black Belts was running a value stream analysis. Creating the current state map was relatively easy since the participants understood their function and the way that information and inventory flowed along the […]

Read more »

Is 5 Times Enough to Ask “Why?”

Published:The 5 Whys approach to root cause analysis is by no means new, nor does it originate in Six Sigma. Yet it is often used in the Analyze phase (of DMAIC [Define, Measure, Analyze, Improve, Control]), especially when significant data on the Xs is not available. Most of us have been there – we gather the […]

Read more »