Why Change Management Is Critical for Digital Transformation

Published:Is change management important for digital transformation? We’re present for an interesting time in the business landscape. Many traditional organizations are modernizing, joining with the times as it were. In part this is thanks to the advent of more advanced technological developments. Some companies embrace them as a matter of their foundation, but […]

Read more

9 Remote-First Companies That Made It Work

Published:What are the remote-first companies that made it work? There are plenty of success stories throughout the history of business. However, little has been said about the remote companies that are making a mark on the landscape of business right now. If you’re looking to lead your remote team, some organizations can serve […]

Read more

The Best Tools For Remote Teams

Published:What are the best tools for remote teams? You can often skip several of the latest and greatest software tools for in-person positions. However, remote teams have specific technological needs, partly thanks to the distance between employees and the workplace. As such, tools come in handy for managing time, communicating, keeping track of […]

Read more

Future of Remote Work: Trends and Predictions for the Hybrid Workforce

Published:What does the future of remote work hold? The shift to remote work has been rather abrupt. While it seems somewhat gradual in retrospect, the numbers behind it don’t lie. That said, the future seems promising for remote work. While we don’t have access to a crystal ball here, we certainly have no […]

Read more

Maintaining Company Culture in a Remote Work Environment

Published:How do you maintain company culture when your entire team is remote? Going hybrid or fully remote doesn’t mean you have to forego maintaining a company culture. Some organizations realize and maintain a vibrant company culture despite the challenges of remote work. It is a matter of simply balancing and planning how to […]

Read more

Common Challenges of Remote Work and How to Overcome Them

Published:What are the common challenges of remote work? Remote work itself has become a regular part of many offices. However, there are some drawbacks to this hands-off workflow. When remote work started becoming more prevalent at the start of the pandemic, these drawbacks weren’t given much thought. That said, you give anything significant […]

Read more

Tools and Platforms to Boost Productivity in Remote Teams

Published:What tools can boost productivity in remote teams? Finding the right workflow for remote teams is paramount to their continued success. As such, planning to use the right tools and developing a solid workflow is a great way to ensure your team stays on track. Finding the right blend can be challenging, but […]

Read more

How to Build a High-Performing Remote Team

Published:How does an organization build a high-performing remote team? Remote work has become all the rage over the last few years, with organizations without a heavy need for on-site personnel switching to the model. The benefits have been discussed ad nauseam, like the lower rent for many organizations and reduced overhead. However, little […]

Read more

How to Implement Design Thinking in Cross-Functional Teams

Published:How does design thinking apply to cross-functional teams? We’ve spent a fair bit of time here discussing the benefits and reasons why you want to use design thinking in product design. However, little has been said about how it applies to cross-functional teams. Thankfully, this approach benefits from multiple disciplines and specialties collaborating. […]

Read more

Design Thinking in Practice: How Leading Brands Innovate

Published:What does design thinking in practice look like? There has been much talk about its power and efficacy. However, when you peruse the many online resources available, the picture is incomplete. We know it’s a human-centered take on product design, but what does that look like in motion? Design thinking in practice isn’t quite what […]

Read more

The 5 Phases of Design Thinking: A Step-by-Step Guide

Published:What are the 5 phases of design thinking? Design thinking is a human-centric approach to product development. However, it operates in five distinct phases when broken down into its core elements. As this is an iterative approach, some phases bear repeating, provided the product hasn’t met its design specifications. So, with that in […]

Read more

Design Thinking Tools to Enhance Creativity and Problem-Solving

Published:What design thinking tools are companies using to make the most of their work? Design thinking isn’t a new concept, but it has caught in a big way over the last decade. As such, a whole cottage industry of software and other tools has sprung up to accommodate the needs of teams. Good […]

Read more

The 10 Companies That Do Design Thinking The Best

Published:Which companies do design thinking the best? Design thinking is a relatively new approach to the likes of product delivery. While products are often drummed up with the customer in mind, few approaches consider the customer’s needs before even analyzing the problem and developing a solution. That said, some companies are embracing design […]

Read more

The Industries That Benefit Most from Design Thinking

Published:What industries benefit the most from design thinking? Design thinking is a growing approach to the entire conceptualization and execution of new products to market. However, despite its increasing popularity, it is better suited for certain industries. Now, that isn’t to say your organization should forego implementing design thinking. It all depends on […]

Read more

Key Digital Tools Driving Business Agility

Published:What tools are needed to create business agility? An agile business can adapt and roll with the punches. I don’t mean a momentary setback but events that a business can easily adapt and overcome. In software development, this methodology is known as Agile and is one of the driving forces behind modern development […]

Read more

The Most Popular Tools For Data-Driven Decisions In Business

Published:What tools are businesses using for data-driven decisions? There is plenty to be said about the proliferation of data in the workplace. However, one thing is clear: it is here for the long haul. As such, learning how to manipulate this data for your organization’s well-being is simply part and parcel of the […]

Read more

How to Build a Data-Driven Culture in Your Organization

Published:Is it easy to build a data-driven culture for your business? Data is a driving force in any modern organization. Even mom-and-pop stores are leaning on what they can glean from the digital revolution. As such, it is more important than ever to take the steps to create a data-driven culture to take […]

Read more

Big Data vs. Small Data: Which Is Right for Your Business?

Published:Big data vs. small data, which one are you choosing for your business? Data is a big market right now, something that it has held the distinction of for the last decade or more. Data drives business decisions, calls forecasts for future trends, and so much more. As such, it helps to have […]

Read more

Step-by-Step Guide to Conducting an FMEA

Published:What’s the best process for conducting an FMEA? If you want to start implementing lasting changes into your production line, FMEA is one of the top ways to get things rolling. However, there is a certain procedure you’ll want to follow to make the most of your efforts. If you’re new to the […]

Read more

FMEA in Product Development: Reducing Risk Early On

Published:How can you use FMEA in product development? I’ve talked at length about using FMEA as a means of rectifying problems in production. However, you can apply the methodology to the design process of any product or service you’ve got in the works. It isn’t similar to DMAIC, as DMAIC is generally used […]

Read more

Common Pitfalls in FMEA and How to Overcome Them

Published:What are the most common mistakes you can make with FMEA? As a framework, FMEA is aimed at creating lasting solutions to potential problems before they even arise. However, that doesn’t mean it’s completely foolproof. As we’ve seen with many of the tools of the trade, there is certainly a right and a […]

Read more

Real-World Examples of FMEA in Action

Published:How does FMEA work in the real world? We often discuss concepts, methodologies, and frameworks in a vacuum. However, understanding the realistic applications of a useful and quality-driven framework like FMEA pays off in the end. So, with that in mind, let’s look at a few examples of how FMEA is implemented in […]

Read more

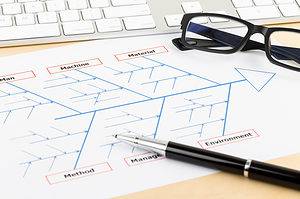

Mistakes When Using Fishbone (Ishikawa) Diagrams

Published:What mistakes are common when using Ishikawa diagrams? As one of the easiest tools to use in the Lean Six Sigma toolbox, there is a very real potential for misusing these diagrams. It isn’t necessarily a lack of knowledge that hinders these tools, but other common pitfalls that make them less effective than […]

Read more

The Best Tools To Make a Fishbone (Ishikawa) Diagram

Published:What are your best resources for making a Fishbone diagram? You might not always have a pen and paper handy, and you might need something more readily presentable for leadership. So, what do you do? You’d likely turn to some of the many popular and powerful software packages available for visualization tools. With […]

Read more