© Ground Picture/Shutterstock.com

Key Points

- FMEA is a means to refine processes and reduce the points of failure.

- Proper implementation of FMEA means you’re implementing lasting solutions in your production lines.

- FMEA can apply to any industry, regardless of the final deliverable.

How does FMEA work in the real world? We often discuss concepts, methodologies, and frameworks in a vacuum. However, understanding the realistic applications of a useful and quality-driven framework like FMEA pays off in the end.

So, with that in mind, let’s look at a few examples of how FMEA is implemented in the real world with a few hypothetical scenarios. This isn’t taken directly from internal documents, but rather examples derived from natural experience. Hopefully, you’ll come away from this with a greater understanding of the power and efficacy of FMEA.

What Is FMEA?

©Ground Picture/Shutterstock.com

FMEA is short for Failure Mode and Effects Analysis and is a process refinement framework that allows for the design of products with potential failure modes in mind. This isn’t too dissimilar to the DMAIC and DFSS frameworks frequently seen in Lean Six Sigma. However, where this strikes out on its own is with the design of these failure states accounted for.

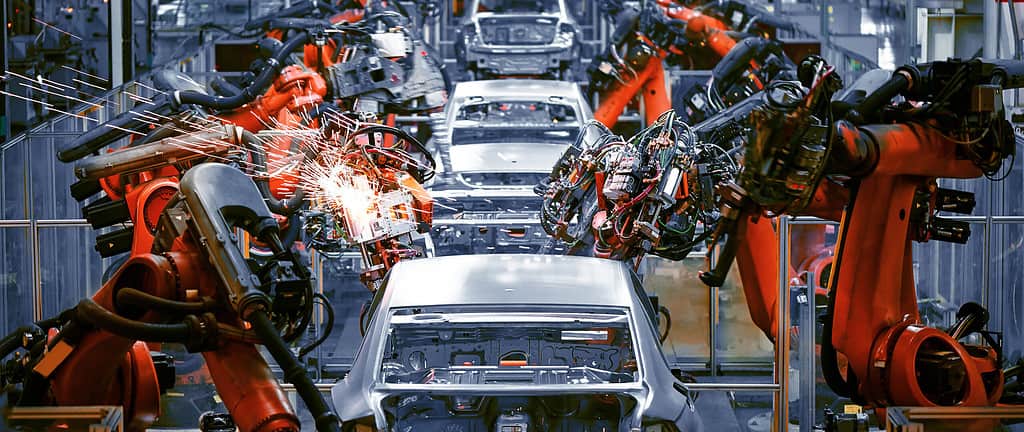

More often than not, you’re seeing plenty of products and services on the market that utilize FMEA. Automotive manufacturers are likely to keep it in mind, especially given the complex workings of the average automobile.

It’s a simple enough framework to implement into your workflow. You can still utilize tools and methodologies like DMAIC concurrently with FMEA. It just depends on how you choose to implement things as far as determining the overall efficacy of things.

Steps in Creating a Solid FMEA Framework

Before diving into real-world examples of FMEA at work, let’s lay down the ground rules for setting up your own FMEA framework. This is a flexible approach, but it requires a fair amount of legwork before you’re fully set to move forward. As such, understanding the steps needed and how to best implement them is going to have you fully prepared moving forward.

There are a few variants of FMEA to consider, but that isn’t the point of today’s guide. It is worth learning these variants and how to apply them to your production line, but learning the basics will be better as a primer.

Review Your Process

When drafting up an FMEA game plan, the first natural step is to take a closer look at the overall construction of your process. You want to review your process flowchart to determine the individual components of your process to further help in identifying potential failure modes.

Brainstorm Failure Modes

You should have your key process components identified at this stage, so moving forward you’ll want to determine any potential failure modes that can occur. This can be a bit time-consuming, but remember this step is prone to scope creep. If it feels like you’re trying to account for too much, you likely are. Pare down things until you get manageable sets of failure modes that you can work with.

List the Effects of These Failure Modes

What happens during these failure points? This is what this step is all about. You want to take the time and energy to list the effects of each, as this will be a key factor in determining what to focus on next. This is where you’ll list things like manufacturing defects, potential pain points in assembly, and so forth.

Give Severity Rankings

Now that you’ve got your failure modes identified and their effects detailed, it’s time to give them severity rankings. This step isn’t as hard as you might think. You simply want to determine which of these steps has the largest impact on the overall production line. A simple defect in printing on packaging might not be as severe as an outright component failure.

Give Occurrence Rankings

How often do these effects occur throughout your production? This might take some time to determine, but is well worth cataloging in-depth. You want to have accurate data when it comes to how often these things happen in your production line.

Determine the Detection Methods

One of the key things to keep in mind when constructing this gameplan is simply to determine how you’ll detect these effects as they happen. Machine failure is fairly telling, as it might grind the whole of production to a halt. However, determining something like a faulty wiring harness might be something that only gets caught in quality control.

Develop Solutions

With your occurrence, severity, and detection rankings in hand, you’re ready to calculate your RPN. This formula is constructed as Severity * Occurrence * Detection. When you’ve determined the RPN of each item in your plan, you’re ready to sort and develop solutions. You’ll want to develop solutions for things that have the highest overall RPN and work your way down.

Real-World Examples of FMEA

With any luck, you know how to create a solid and effective game plan when it comes to implementing FMEA with your existing or new processes. Now, it’s time to give some real-world examples of FMEA in action. These are mostly hypotheticals but are plausible enough that they could be happening right now as you read this.

FMEA is a concept I do have some familiarity with, especially in tech. Computers are fickle things after all, and knowing how and when to account for potential failures can mean the difference between business continuing as usual or losing considerable sums while you try to rectify issues.

Creating an E-commerce Website

First up on our real-world examples of FMEA is an e-commerce website. The modern website has plenty of considerations to keep in mind. As such, when a firm sets out to create a new website, they have quite a lot to consider.

For our e-commerce website, one of the top failure modes is going to be issues with the payment screen. This isn’t going to be a regular occurrence, so it’ll take quite a bit of time to determine how often this is happening. Additional failure modes are going to be pages that don’t load anything, and not recognizing user credentials

Through extensive unit testing, we found the lack of user credentials being recognized is the least common, so it has a lower RPN. We conduct extensive testing before developing a solid pipeline to make sure that our payment screen is both effective and secure.

Developing a New Automobile

Automobiles are complex mechanisms these days. You have plenty to keep in mind, especially when launching a new car model. So, for our next real-world example, we need to consider all the possible failure points in the car before it leaves the assembly line.

The top concern is faulty materials from our supplier. I’m talking unsightly blemishes in treated leather, visible slag on raw metals, and things of that nature. Now, after ranking out things like fault assembly and a lack of quality control on certain aspects, we need to develop a solution.

We don’t have any control over the raw materials themselves, but we can vet the materials before they reach the assembly line. Our implemented solution is going to dedicate a few skilled workers to determine whether there are faults, blemishes, or other unsightly things. This helps reduce the rate of failure before we even begin assembling the automobile.

Designing a Smartphone App

Smartphones are ubiquitous these days, and apps are big business. However, developing a new app can be fraught with unforeseen complications. So, it makes a perfect fit for our next real-world example of FMEA in action. Smartphones have a few different considerations to keep in mind.

Firstly, with our app, we’re having issues with the use and multiple touch inputs. Now, if this was a game, this might be a top consideration, but we’re focusing on cataloging movies in a household. As such, the assigned RPN is going to be considerably lower with this potential failure mode.

Our top failure mode is going to be users not updating the app regularly. As such, with the higher RPN ranking, we know this needs a lasting solution developed. With that in mind, we urge the developers to add a reminder screen so users update the app regularly.

Launching a New Home Appliance

©Ground Picture/Shutterstock.com

Our last real-world example is the launch of a new home appliance. These are considerably less complex as a whole compared to something like a car, but there are still plenty of failure modes to cover. In our case, we’re covering a toaster. During testing, we noted that the top failure mode seen is the toaster sticking and burning toast.

Additional failure modes to consider are the toaster settings being applied and popping up a little too early. With most of this, we can determine that the toaster’s loading mechanism needs to be calibrated on each toaster.

With our higher-ranked RPN item in mind, we set out to calibrate said loading mechanism and thoroughly test it before shipping it out to customers.

Why FMEA Works

FMEA as a concept is one of the most effective tools for eliminating faults and defects in your production line. One of the most noteworthy elements to consider when developing an FMEA plan is that you’re identifying the individual points of failure that are of top concern.

This might seem like a minor deal to most folks, but knowing the points of failure and addressing them guarantees that you’re providing quality deliverables and services regularly to your customers. After all, businesses are about providing quality to your customers, rather than just shipping whatever barely passes the grade.

Other Useful Tools and Concepts

Still want to keep reading? There’s plenty to learn about when it comes to making your business the best it can be. You might want to keep abreast of the ethical challenges concerning artificial intelligence in your business. AI is a huge deal right now, but it raises some ethical concerns, especially where your rank-and-file employees are concerned.

Additionally, you might want to learn about common mistakes that occur when you’re creating Ishikawa diagrams. This is one of the most basic QC tools you can use within Lean Six Sigma, but that doesn’t make it foolproof. Our extensive guide covers common mistakes users make when constructing their own Ishikawa diagrams.

Conclusion

FMEA comes in many different variants, but learning the basics of how it works can reduce the time you spend reworking elements. Take the time to plot out your processes, rank the failures, and put solutions in place and you’re likely to see production running smoothly as silk.

The image featured at the top of this post is ©Ground Picture/Shutterstock.com.