The “Great Indian Bazaar” – the rapidly growing and evolving Indian retail market – presents special and daunting distribution challenges for fast-moving consumer goods (FMCG) products. For a typical producer, about 100 stock keeping units (SKUs) flow through 40 to 50 depots to 2,000 to 3,000 distributors to more than a million outlets varying in size from the tiniest corner shop to large supermarket outlets.

Depending upon the product and the company’s manufacturing strategy, from a handful to as many as 50-plus plants spread out throughout the country. Inevitably, not all plants produce all the products. At the end of the supply chain, every organization attempts to minimize shortages and stock outs.

The improvement effort in this case study was aimed at increasing the availability of finished goods stocks at the distributors by using Total Quality Management (TQM) principles such as just-in-time, value stream mapping, employee involvement, eliminating non-value-added stages and initiating a demand pull supply in the flow. Part 1 described the transformation of the link at the end of the supply chain – from depot to distributor. Part 2 describes the model proposed for the upstream links – between the warehouses at the factories and the depots. Part 3 goes further upstream and describes the model for market-mix-led demand-pull production and its dramatic effect on improvement of availability.

Step 1: Define the Problem

The company supplied about 70 SKUs to more than 500 distributors through 13 depots from 24 factories in the Western region. After discussing the situation, the company decided to develop the market-mix-led demand-pull model for one product line with 13 SKUs produced from two factories through the 13 depots to 200 distributors. The metric for the project involved product availability, with availability being defined as the every SKU being available every day at every stock point. The unit used to measure it was defined as a data point (DP). A DP was defined as follows:

- 1 SKU available on 1 day at 1 stock point = 1 DP

- 2 SKUs available on 1 day at 1 stock point = 2 DPs

- 2 SKUs available on 2 days at 2 stock points = 8 DPs

Therefore, for the test population,

% availability = % DPs / (maximum DPs during period)

A stock point could be a depot or distributor. With the depot to distributor system already following the demand-pull model, the metric was applied to depot availability. The current state showed a 10 percent stock out of DPs. In phase one, the team agreed to try to reduce this by 50 percent to 5 percent stock out of DPS.

Step 2: Root Cause Analysis

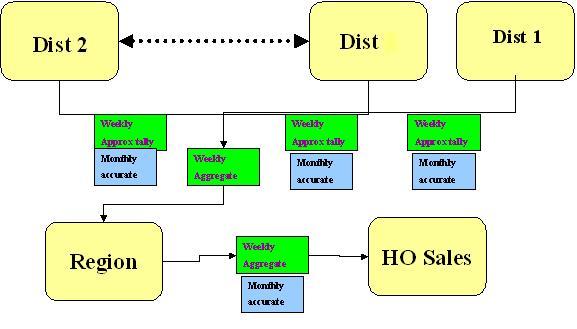

The prevalent planning system was a forecast-based supply push system. The team completed a map of the forecasting system, shown in the figure below.

Typically, the sales system added up the actual sales once per month to get an accurate count. The expected demand from the sales team’s estimates spread out through the field, planned marketing promotions and monthly trends also were considered when issuing the sales forecast for the next month.

There were two problems:

- This forecast suffered from the typical bullwhip effect – shortage/excess of stocks were magnified at each stage and led to wild swings in demand – which only increased the amplitude of the bullwhip wave.

- The sales forecast for any month was available one week after the month had begum and the real production plan only emerged nine days after the month had begun. This delay produced two serious distorting effects. First, for the first 10 days of the month, production followed the demand of pattern the previous month’s days 1-10. Second, the supply chain had only 20 days to react to changes in monthly demand patterns.

Mismatches between demand and supply were bound to be the outcome of the current process.

Step 3: Generate Countermeasure Ideas

The team drew the solutions from just-in-time principles. They believed a dramatic reduction in the sales-to-planning cycle could be achieved by implementing demand-pull production. They reduced the number of stages needed to generate the plan by:

- Aligning specific factories to specific depots for specific SKUs

- Monitoring stock levels at its customer depots for each factory daily

- Replenishing to agreed maximum stock levels at agreed frequencies depending upon downward supply

- Conducting fortnightly production planning based upon market aggregated supply to distributors during the past fortnight adjusted for stock levels at factory, depot and distributors

- Introducing special promotions and production requirements for each factory, to be communicated by central planning

Step 4: Test the Idea

Key personnel in the factory, planning and logistics departments were trained in the demand-pull model. One product line with multiple SKUs produced in two factories and supplied to 13 depots was selected for the trial. Formats and operating principles for combinations of production mix to suit varying sales requirements were developed to set the stage for the trial. Modeling was done for four fortnights by generating the demand pull locally and comparing it to the demand that would have been produced with the monthly supply-push planning system. The employees discovered that the mix required was different, but it would only prove beneficial and not result in a supply disaster.

Step 5: Check the Result

The steady improvement in stock out DPs at the distributors and depots are captured in the table below.

Changes in DPs from July to March

| Month | DPs Depot | % Depot | DPs Distributor | % Stock Out |

| July | 2821 | 10.5 | ||

| Sept | 2730 | 5.5 | ||

| Oct | 2821 | 3.5 | ||

| Nov | 2730 | 1.5 | ||

| Dec | 2821 | 0.1 | 43,400 | 1.74 |

| Jan | 2821 | 1.9 | 43,400 | 2.28 |

| Feb | 2548 | 1.3 | 39,200 | 1.04 |

| Mar | 2821 | 1.0 | 47,740 | 0.46 |

The improvements resulted in a 90 percent reduction on stock out days at the depot and 67 percent at the distributor. Also, 0.46 percent DP stock outs at distributors meant a total of 230 stock out days spread over 200 distributors and 31 days (i.e., stock outs must at best be just one or two SKUs stocked out at one point for one or two days, implying virtually zero stock out at the retailers). Likewise, 2,821 depot stock out points over 30 days and 13 depots means very short stock-outs that were made up before loss in sales at the retailer could occur.

After experiencing three months of testing, the operating team, satisfied with the results and having had a long exposure to TQM, decided to roll out the model on its own.

Just-in-time is a powerful method for improving delivery in a supply chain while reducing stocks, operating pressures and costs. Effective implementation involves cutting cycle times of both Information and materials by converting batch process to flow processes, removing non-value-added activities and establishing decentralized supplier/customer relationships with central control for special circumstances.