“What do you mean, special handling is waste? We can’t stop doing that! Eighty percent of our invoices require special handling!”

— Medtronic accounts payable employee, May 24, 2005

Lean Six Sigma at Medtronic

Medtronic has combined Lean and Six Sigma to achieve impressive results. In the last two years, Medtronic has graduated 579 Lean Sigma Belts in 29 waves. An additional 500-plus are scheduled for training through wave 45. A total of 217 projects have closed with benefits of more than $62 million, and 325 projects are active with an additional $14 million in benefits forecasted. Every Medtronic business unit and region are involved in Lean Six Sigma.

As at other companies, many of the early benefits of Lean and Six Sigma at Medtronic, a global leader in medical technology, were in manufacturing. In the last year, however, Medtronic also has had notable results from the application of the methodologies in the office – in transactional and administrative processes. Last May, at Medtronic’s world headquarters in Minneapolis, Minnesota, USA, the accounts payable department, a part of the company’s Global Business Solutions organization, completed Medtronic’s first U.S. Kaizen event on a transactional process. The event produced outstanding results and provided many lessons at the company.

How Accounts Payable Was Selected

When its bi-annual employee survey results were published in October 2004, the Medtronic Global Business Solutions (GBS) unit’s score in operating effectiveness was below expectations. In order to find and address the root cause of the disappointing score, a Six Sigma project was commissioned by the organization’s senior vice president. A cross-functional team of employees, led by a Medtronic Black Belt, completed the Define, Measure and Analyze phases. The analysis of the survey data showed that some of the GBS groups scored significantly lower on one question in the operating effectiveness category: “In my work group, we are effective at eliminating unnecessary tasks and steps.” The most significant negative response for this question was in the accounts payable department.

Lesson learned:

The concept of waste (or “muda” in Japanese) is hard for many in service organizations to grasp. When so much workflow is electronic, waste can be especially hard to spot – and to employees, eliminating this waste can initially seem like a disservice to clients and customers.

While Six Sigma tools were used in the Define, Measure and Analyze phases of the project, multiple sub-projects were launched for the Improve and Control phases, some using Lean methods and some SixSigma, depending on the critical Xs. In the case of the accounts payable group, Lean was clearly appropriate to help “eliminate unnecessary tasks and steps.” Lean projects can take months to complete, but in this case, results were needed quickly in order to improve performance, and to validate that employees’ perceptions of operating effectiveness would be improved.

The choice to use a Kaizen event in accounts payable was not an immediately obvious one. While the short-time investment required to make improvements was attractive, there was little precedent for applying what seemed to be a manufacturing process improvement approach in a shared services environment.

Planning for the Kaizen Event

Planning for the accounts payable Kaizen event involved creating a project charter, creating a value stream map of the process to be improved (in this case, non-purchase order invoice processing), and gaining a basic understanding of the types (or families) of transactions.

Day 1 of the Kaizen Event

The participants were all smiles on Day 1, but lurking behind those nervous smiles were doubts. Here are some comments heard that first day:

- “What do you mean we may actually move offices during this week? Moves are scheduled out weeks into the future – there’s a waiting list!”

- “We can’t change computer systems on the fly…what about IS production change controls? They will never allow us to do that.”

- “The imagers and accounts payable processors don’t even report to the same manager…who is going to pay for the cost of any changes? We didn’t budget for this.”

- “I don’t know why we’re spending a week on this. If those guys would just do their job, everything would already be running smoothly.

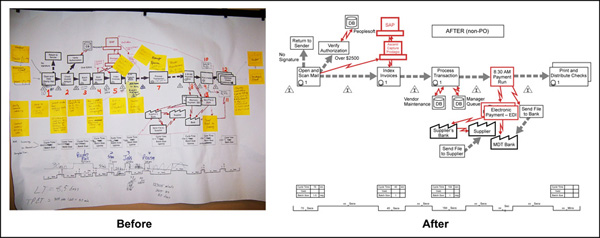

Reviewing the value stream map of the process surfaced many special cases and exceptions, and the map – posted so everyone could study it – was updated with sticky notes.

Opportunities to attack waste included:

- Eliminate shuttle delivery of payments.

- Reduce FedEx delivery of payments.

- Reduce daily distance walked.

- Eliminate sorting of invoices and attachments.

- Index directly from electronic image versus paper.

- Eliminate batching of invoices and attachments.

- Eliminate redundant inspections.

- Eliminate “call-for-pick-up” of payments.

Lesson Learned:

While change management in any Lean Six Sigma project is challenging, condensing the change from four to six months into one week takes careful planning.

Even though the entire accounts payable staff had been briefed about the Kaizen event, as the team made its first-hand observations about waste in the work area, the staff began to wonder what the Kaizen team was up to.

Day 2 Is for Gathering Information

The team documented the sequence of events for each major process step. The members gathered information about tasks and steps, cycle times, inventory, defects and distance walked. Then the team calculated the process Takt time. (Takt is a German word for the rate at which work is produced to meet customer demand.) Next it looked at the balance of the work in the current process compared to Takt time as shown in Figure 2.

To end Day 2, the team mapped the improved/simplified process as shown in Figure 3.

Day 3 the Team Works for Improvements

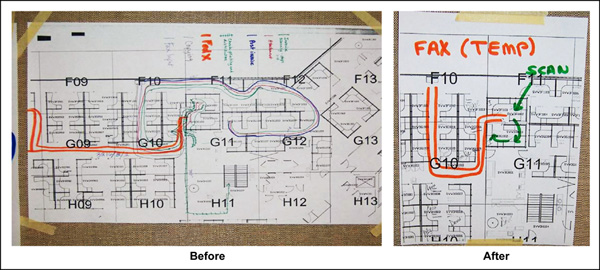

The team began with a spaghetti diagram of the physical flow and worked to find a way to reduce travel by 73 percent. The before and after diagrams are shown in Figure 4.

That activity was followed by a rebalancing of the work. Techniques used to balance the work included single piece flow, standard work methods, moving/combining steps, reducing non-value-added time and changing the sequence of work. In addition, there were a number of 5S improvements to better organize the work areas and make the process more visual. 5S is the Japanese concept for housekeeping. The results are shown in Figure 5.

Results of the Kaizen Event

The event was extremely successful. Table 1 below offers an overview of positive results.

| Table 1: Results of Kaizen Event | |||||

|

Metrics |

Original |

Goal |

Estimated at |

Actual: |

Improvement |

| Lead Time |

8.5 days |

5.0 days |

4.0 days |

2.7 days |

68% |

| Total Cycle Time |

5.7 min. |

5.7 min. |

5.0 min. |

2.9 min. |

49% |

| Inventory (Invoices) |

Old: 3375 |

1985 |

< 1588 |

Old: 1454 |

Old: 41% |

| Walking Distance |

Total/Day: |

No Goal |

Total/Day: |

Total/Day: |

73% |

| Productivity (output/- person/effective hours) |

12.8 |

15.5 |

No Estimate |

15.5 |

21% |

Lesson Learned:

Kaizen events can work as well on transactional processes as they do in manufacturing. And a longer Lean Six Sigma project duration does not necessarily equal better results. In many cases, all of the benefits of a four- to six-month project can be realized in a one week Kaizen.

In addition to the results in the table, the accounts payable department was able to avoid hiring two employees planned to support a forecast of additional volume. The dramatic improvements are reflected in the invoice processing durations in Figure 6. This sub-process improved from negative sigma performance to about 4.1 sigma in one week.

Lesson Learned:

Making electronic processes visible/visual is challenging but possible, and it is a critical part of the Control phase post-Kaizen.

At the Post-Kaizen Follow-Up

At the 30-day post-Kaizen review, a number of issues came to light. The Kaizen event results were impressive, but there were some areas of concern. Because so much of the accounts payable workflow is electronic, inventory/queue levels, resource constraints and quality problems are not visible to everyone in the process. Making them visible would require either more system changes or creating some other vehicle to share this information. Addressing these concerns led to some additional learning about the overall Kaizen process.

The success of the accounts payable Kaizen event created a high demand for Kaizen events from other office/transactional process owners. Encouraged by it own success, the accounts payable department also is undertaking additional Kaizen events and has started several Six Sigma projects.

Conclusion: Higher Scores and More Kaizen Events

Lesson Learned:

Kaizen builds organizational momentum and overcomes skepticism about Lean Six Sigma in a short period of time.

What about the accounts payable employees’ viewpoint? Did the Kaizen event change how they saw operating effectiveness? Based on the re-survey of accounts payable employees 45 days after the Kaizen event, the answer is a resounding yes. The score for operating effectiveness improved 15 points. Even a five-point improvement would have been statistically significant. Medtronic plans to monitor this over time to ensure the company can hold the gains.

For future GBS Lean projects, the simple criteria will become: Why not a Kaizen event? Unless there is a good reason not to, GBS Lean projects will be approached with Kaizen events. Medtronic has not yet attempted to conduct a Six Sigma project in a five-day Kaizen event, but that is certainly an experiment whose time has come.