The Design for Six Sigma project has followed a IDOV roadmap that includes the Identify, Design, Optimize and Validate phases. By the time the project reaches the Validate phase, the team has focused for weeks or months on driving the project toward completion. Working through the IDOV process, the project team identified the problem in terms of the voice of the customer, then designed an optimized solution. Most of the effort was spent during the Identify and Design phases. There is benefit to spending more time at the beginning of the project. It provides a higher quality product at the point of implementation and is more efficient in terms of cost and time than reworking the design after implementation in an attempt to find an optimal match to the voice of customer.

Validate Phase Is Critical to Success

As important as the initial phases of the IDOV process are, the last step – the Validate phase – is critical to the long-term success of the project. The transition from the Optimize phase to the Validate phase signals the end of the product creation process and the beginning of the effort to institutionalize the new product design. A poorly implemented Validate phase could mean the supply chain is not ready to support the product, or the product was not validated against critical-to-success (CTS) factors identified by the customer. Issues also could arise if the Black Belt retains support and ownership of the product due to a poor project transition during this phase.

There are two key elements in the Validate phase.

Confirm Deliverables and Level of Quality

The first element is to confirm that the required deliverables have been met and that they can be produced at a capable level of quality. Specifically, is the product capable of achieving the needs of the customer nearly all of the time? To determine if this is the case, the project team must migrate the product from its experimental or test environment to a production environment. The project team may require the IT department or operational support to accomplish this.

In addition to moving the product to a stable environment, the team must update the scorecard with quality metrics important to the customer. Early in the project, CTS factors were identified using voice of the customer data. These factors are the measurement system used to gage the success of the project.

Looking at a Scorecard Example

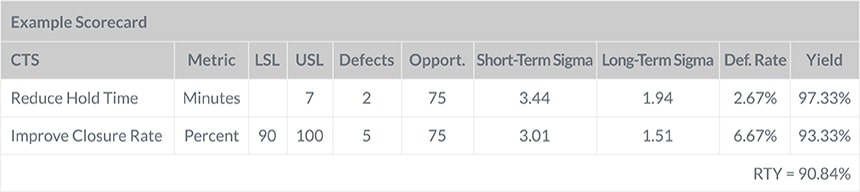

Through the use of a scorecard (see the table below), the team can show how the new product or service is performing. In an example where the deliverable are an improved call center service, the CTS’s are to reduce hold time and improve call closures by resolving issues during the first phone call. These CTS factors are measured in minutes and percent of total closures, respectively.

For each CTS factor, lower and upper specification limits are established. In this example, there are 75 samples for each CTS factor. Note the process sigma levels. The short-term sigma levels greater than 3 indicate the process as being “capable” of meeting the customers’ needs. The long-term sigma is figured by applying a 1.5-sigma shift from the short-term sigma level. The long-term sigma is an estimate without analyzing long-term data. Finally, figuring the defect rate and yield, the scorecard displays a rolled throughput yield (RTY) for the entire process.

For each CTS factor, lower and upper specification limits are established. In this example, there are 75 samples for each CTS factor. Note the process sigma levels. The short-term sigma levels greater than 3 indicate the process as being “capable” of meeting the customers’ needs. The long-term sigma is figured by applying a 1.5-sigma shift from the short-term sigma level. The long-term sigma is an estimate without analyzing long-term data. Finally, figuring the defect rate and yield, the scorecard displays a rolled throughput yield (RTY) for the entire process.

In addition to the scorecard, statistical process control (SPC) calculations can show a detailed assessment of the health of the process. SPC statistical charts reflect common-cause variation and special-cause variation based on process statistics. The most common charts are p-charts for attribute data, I-MR charts for attribute data that is convertible to percentages, and xBar-R or xBar-S for variable data.

Transition to the Process Owner

The second key element in the Validate phase involves the transition of product ownership to the process owner. An important aspect of this transition is the ability of the supply chain to continue functioning efficiently. Poor supply chain readiness can lead to poor performance of the overall system resulting in service delays, added overhead costs or variation in the process.

It is important to include a transition plan in the project deliverables. A good transition plan should include how and when the process owner will take control of the product and associated process from the project team. There are two documents that will assist the team in this effort – the failure modes and effects analysis (FMEA) and the control plan. The FMEA contains a list of all the potential failure modes that may occur in the process stream and an action plan for managing risk due to product failures within the new system. The control plan is a list of the key input and output variables that must be controlled to achieve a good process. The control plan contains the function of the product, the measurement system used to monitor the level of control, the frequency and sample size of the measurement, and references to any standard operating procedures (SOPs). The control plan is presented to the process owner as a roadmap for maintaining a controlled process.

Conclusion: Design Project Should Finish Strong

For any number of reasons, wrapping up or closing a project can be overlooked. Getting through the last step may not appear as important as gathering the voice of the customer or establishing a robust design. But concluding a project by validating the impact and performance of the product, ensuring a ready supply chain, and effectively handing over ownership of the product to the process owner are critical elements in the success of an IDOV Design for Six Sigma project.