What is Total Quality Management?

Total Quality Management (TQM) is a management system that was developed back in the 1950’s and has been successfully deployed in a wide variety of industries from the 1980’s onwards. At its core TQM is a management system for a customer focused organization that involves all employees in continuous improvement. It uses strategy, data and effective communications to integrate the quality discipline into the culture and activities of the business. Its approach is very similar in concept to international quality standards such as ISO9000 series and is fully aligned with lean and Six Sigma methodologies.

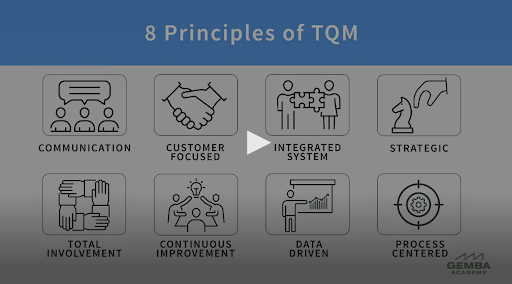

TQM typically adopts 8 core guiding principles and these are:

- Customer focus, customer first: an unwavering focus on the customer experience in all interactions with the organization. From initial contact through purchase and aftermarket support, the customer should always be the main priority.

- Employee ownership, employee involvement: all employees participate in working toward common goals. Total employee commitment can only be obtained after fear has been driven from the workplace, when empowerment has occurred, and when the proper environment has been created.

- Process based, process centered: TQM focuses on the creation and implementation of processes that provide organizations with the ability to find success, repeat and sustain.

- System integration: TQM strategies revolve around leveraging every asset available to the company. This is best achieved through system integration that combines disparate parts of the business into a single, well coordinated machine.

- Communication: during times of organizational change, as well as part of day-to-day operation, effective communications play a large part in maintaining morale and in motivating employees at all levels.

- Data driven, fact based: data is leveraged for the improvement of the organization and decisions are made based on quantifiable facts not opinion.

- Strategic and systematic approach: a critical part of the management of quality is the strategic and systematic approach to achieve an organization’s vision, mission, and goals. This process, called strategic planning or strategic management, includes the formulation of a strategic plan that integrates quality as a fundamental component.

- Continuous improvement: continuous improvement drives an organization to be both analytical and creative in finding ways to become more competitive and more effective at meeting customer expectations.

As with most quality management systems and methodologies the success of deployment is highly dependent upon how TQM is introduced to a business and the culture and appetite for change management.

3 benefits of TQM

Like most management systems and methodologies there are a number of benefits to consider before deployment of TQM. Let’s explore some of these further.

1. It puts the customer front and center

The customer ultimately determines the level of quality you need to hit. No matter what an organisation does to foster quality improvement, whether that be training employees, integrating quality into the design process, the customer determines whether the efforts were worthwhile. TQM brings the customer into sharp focus for all of your employees.

2. It involves and engages all employees

As the saying goes, continuous improvement and quality starts with people. Without the support and commitment of your workforce, quality improvement will falter. TQM fosters collaboration, all employees working to a common goal and meeting customer requirements.

3. It is process and data driven

Much like the core principles of Six Sigma and the DMAIC process, TQM strives for process thinking and decisions that are based on data, not opinion or hearsay. TQM requires organizations to collect, measure and analyze process data continually to understand current performance and opportunities for improvement.

Why is TQM important to understand?

By deploying TQM we have a logical and structured approach to embedding quality into a business..

It forms a key part of your strategic business plan

All organizations want to grow their profit margin, retain and grow their customer base and hit high levels of customer satisfaction. If your strategic business plan has these elements then deploying TQM aligns your strategic goals with the day to day activities of delivering quality and continuous improvement.

It generates employee and customer satisfaction

The deployment of TQM and its guiding principles ensures all employees are involved with a no fear and no blame environment, fostering engagement and delivering high levels of satisfaction. Customers are satisfied too as the efforts of the whole company are focused upon delivering the right product with exceptional quality every time.

It has the power to differentiate you from your competition

Most companies will have a quality manual, some will adopt the principles of continuous improvement but the companies that stand out from the crowd are those that fully embrace and embed a TQM system.

An industry example of TQM

A Tier 1 supplier to the rail industry had been externally audited for quality compliance and a number of non-conformances were reported. The audit report initiated a fundamental review of quality systems and quality management within the organization and the Director of Quality, having previous experience of working in companies that had embraced TQM, gained agreement from the Board of Directors to implement TQM.

Having assembled a cross functional team the initial activity was to review the 8 guiding principles of TQM and map if and how these were being delivered in the organization today. In addition the non-conformances from the quality audit were reviewed and mapped to TQM deliverables. Having completed this initial activity it was found that 3 core principles of TQM were not embedded in the business and these would be the focus areas. The 3 areas, data driven, employee involvement and continuous improvement were each assigned a working group to better understand the development and deployment actions required to successfully deliver these elements of TQM.

After an initial 3 month review and trial deployment period, an internal audit was scheduled with a focus on the 3 core TQM principles and the non-conformances from the external audit. Significant progress had been made across not just the 3 focus areas but all 8 guiding principles and the opportunity for non-conformance replication had been significantly reduced.

3 best practices when thinking about TQM

As with many quality centric management systems there are some key things to consider when deploying TQM, let’s explore three of these.

1. Deliver clear and consistent communication

Continuous improvement inevitably involves organizational and product change which can be unsettling. Effective communication is a key enabler to the delivery of TQM, maintaining employee morale and motivating employees at all levels.

2. Play the long game

TQM is no silver bullet, it requires long term commitment and dedication. If you plan for a short term intervention then you may hit your target but then lose all your good work. Remember to sustain and embed quality and continuous improvement is the ultimate goal.

3. Embed quality in everything that you do

You and all your employees need to live and breathe quality and continuous improvement. Everything you do has a razor sharp focus on customer requirements and value. Banish those defects and say no to rework.

Frequently Asked Questions (FAQ) about TQM

What does TQM stand for?

TQM stands for Total Quality Management, a well known business management approach to delivering quality and continuous improvement.

How many principles are there in TQM?

Whilst the number quoted may vary, most often TQM is recognized as having 7 or 8 guiding principles for successful delivery. These principles include, for example, customer focus, employee involvement and process centered thinking.

What is the impact of TQM?

The aim of TQM is to involve all employees in the relentless pursuit of continuous improvement to meet customer requirements via an embedded quality management system.

It’s a wrap on TQM

Whilst the methodologies of Lean and Six Sigma have become the go to continuous improvement standards of the last 30 years, TQM still fights its corner. The guiding principles, if thoroughly adopted, will bring certain business success and customer loyalty.