Key Points

- TPS is a comprehensive methodology for process improvement.

- TPS serves as the inspiration for Lean.

- Proper implementation of TPS can lead to greater overall productivity and efficiency.

The Toyota Production System (TPS) serves as the foundation for Lean Manufacturing. Let’s explore this powerful method for improving your processes.

The Toyota Production System (TPS) is a manufacturing philosophy and a set of management practices developed by the Toyota Motor Corporation. It emphasizes continuous improvement, just-in-time production, and efficient use of resources, to maximize customer value and minimize waste. TPS has been widely adopted in many industries and is often referred to as Lean Manufacturing.

What Is TPS?

Japanese industrial engineers developed TPS between 1948 and 1975 built upon the original approach created by Sakichi Toyoda, the founder of Toyota, his son Kiichiro, and Taiichi Ohno, an industrial engineer. Toyota Motor Corporation first published a description of TPS in 1992 and later revised it in 1998. It is important to note that TPS was originally conceived based on two concepts: production management and people management. Unfortunately, many organizations focus primarily on the production element and ignore the impact of the human element.

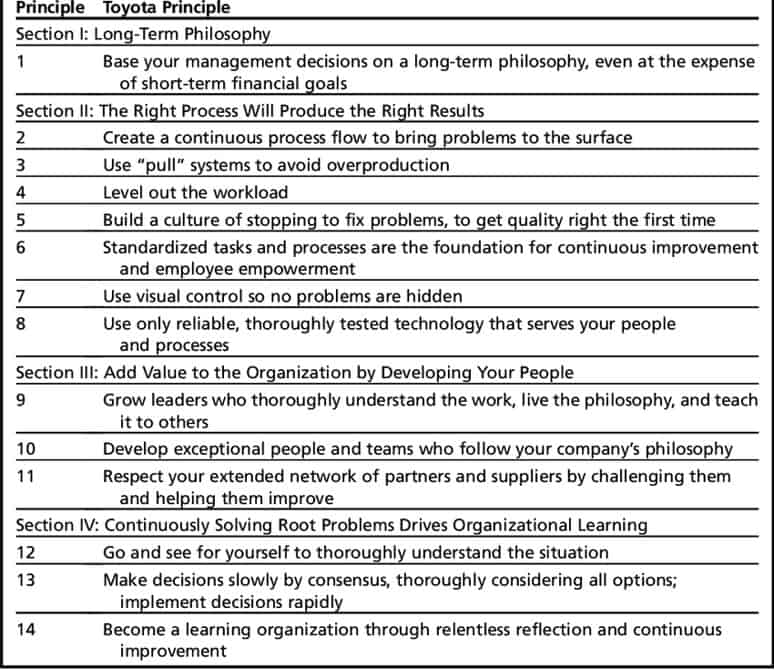

The main objectives of the TPS are to eliminate overburden (muri), reduce inconsistency and variation (mura), and reduce and eliminate waste (muda). The key principles of the TPS are:

1. Apply a long-term philosophy – Always go for the long-term instead of the short-term.

2. Create continuous flow – There should be little to no delay from the time something leaves inventory until the final point of sale.

3. Use pull and avoid overproduction – Develop a balance between customer demand and production. Eliminate excess inventory.

4. Heijunka – You must maintain a pace that does not overexert the company.

5. Build the right culture – The lean processes of the Toyota Production System should be applied throughout your organization.

6. Standardize tasks – This will result in greater consistency and fewer defects.

7. Use visual control – Use visual management boards to guide people on what to do and how they are doing it.

8. Use only tested technology – Don’t overly rely on technology.

9. Grow leaders who live the philosophy – Develop leaders who can combine both the production and human elements of the TPS.

10. Develop people and team – Teamwork can only be successful if you respect each other.

11. Respect your outside forces – Treat your suppliers and other outside organizations as your partners.

12. Observe and reflect – Embed a philosophy of continuous improvement throughout your organization.

13. Decide slowly, implement fast – Make data-driven decisions.

14. Practice reflection all the time – Strive to become a learning organization.

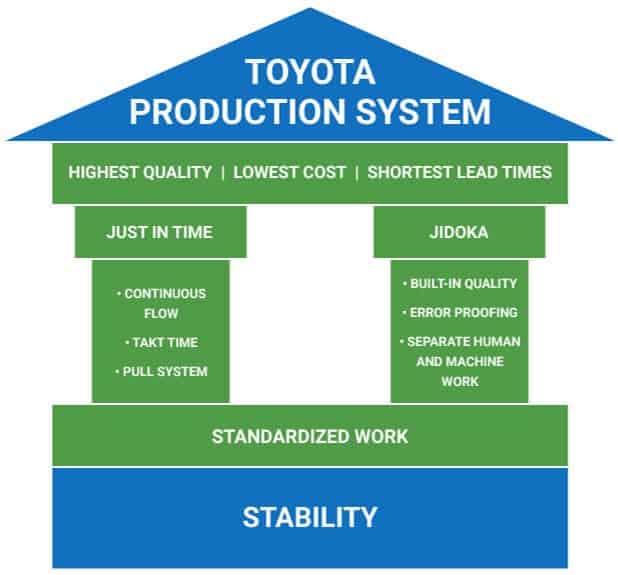

The TPS is often shown as the TPS House:

Is TPS Just Lean?

While Lean is heavily inspired by TPS, that isn’t the whole picture. TPS is a completely independent methodology and set of tools. While Lean does crib heavily from TPS, you can implement principles and tools from both to make your organization shine in your industry.

Benefits of TPS

Here are some of the benefits to your organization if you utilize TPS.

- Increased efficiency – TPS focuses on reducing waste and improving flow in production processes, leading to greater efficiency and productivity.

- Higher quality – TPS emphasizes continuous improvement, empowering workers to identify and eliminate defects in the production process, leading to higher-quality products.

- Lower costs – By reducing waste and increasing efficiency, TPS helps lower production costs and increase profitability.

- Increased flexibility – The just-in-time production approach of TPS allows for faster response to changing customer demands, increasing production flexibility.

- Employee empowerment – TPS places a strong emphasis on involving workers in the improvement process, leading to increased job satisfaction and a more engaged workforce.

Why Is TPS Important to Understand

There are several reasons why it is important to properly understand the nuances of TPS.

TPS Is a Philosophy and Management System

TPS is a management system, not a set of improvement tools. It encompasses several methodologies like Lean and Six Sigma so that is where the tools come from.

The Human Element Is Critical

Although originally developed by industrial engineers to improve production, TPS has a secondary major component based on respect for people.

Flexibility

While TPS refers to the Toyota Production System, it can also be applied to almost every facet of your organization.

An Industry Example of TPS

A large healthcare system decided to implement TPS in their facilities. The application of TPS was focused on operational aspects using lean tools. A more integrative approach focused on the task, structural, and cultural level of the organization. Below are some of the conclusions from their implementation:

- All work must be highly specified as to content, sequence, timing, and outcome – accurate documentation of the Patient’s medical record, developing processes to streamline the workflow, and tracking patient-centered outcome measures.

- Every customer-supplier connection must be direct, and there must be an unambiguous yes-or-no way to send requests and receive responses – direct communication between the patient and the caregiver, improved communication between caregivers regarding the patient’s condition and plan of care, and secured access to patient information.

- The pathway for every product and service must be simple and direct – develop and implement a “Clinical Pathway” for each treatment initiative based on the “best practice” methodology.

- Any improvement must be made in accordance with the scientific method, under the guidance of a teacher, at the lowest possible level of the organization – identify quality improvement projects that focus on improving the workflow of front-line staff and patient safety.

Integration of TPS in Healthcare

TPS Best Practices

Here are a few tips for effectively using TPS.

Engage Your People

TPS involves employees at all levels, empowering them to identify and eliminate waste as well as striving for continuous improvement of all processes.

Don’t Preclude TPS In Non-Manufacturing Context

Since the major tenets of TPS are the elimination of waste, continuous improvement, and respect for people there is no reason you can’t apply TPS to all your organizational functions.

Make Use of the Tools and Methodologies of TPS

TPS uses standard work procedures and processes to ensure consistent quality and reduce waste. It also uses root cause analysis to identify and eliminate the underlying causes of problems and defects.

TPS employs a range of Lean tools and techniques, such as 5S (Sort, Simplify, Shine, Standardize, and Sustain), Value Stream Mapping, and Kaizen events, to drive continuous improvement.

Other Useful Tools and Concepts

Looking for other ways to supercharge your production? You might want to take a close look at Deming’s 14 Points. This is a blueprint and methodology for maximizing quality and productivity across your entire organization.

Further, you might need to learn the differences between linearity and repeatability. While these measurements might seem similar at first glance, there are some notable differences to keep in mind.

Conclusion

The Toyota Production System (TPS) is a management concept based on the Just-in-Time system and jidoka which can be loosely translated as automation with a human touch. Its focus is on the elimination of waste and the continuous improvement of processes.

The main goals of TPS are to address three key issues: Overburden (Muri), Inconsistency (Mura), and Waste (Muda). The Principles of TPS can be summarized as follows: