Key Points

- Process stability is consistency in your production outputs.

- Stability does not account for good or bad outputs.

- A stable process isn’t necessarily a capable process.

Stability has many different definitions. This article will discuss the concept in terms of Lean Six Sigma and process stability. Stability will also be contrasted with process capability.

Overview: What Is Stability?

Simply speaking, a process tends to perform consistently over time. Your process may be consistently good or consistently bad but, at least it is consistent and predictable. You can say your process is stable if it is operating only with common cause variation

Stability is one of the characteristics of your process that is determined by using a control chart. A control chart is designed to distinguish between common and special cause variations. By collecting process data over time, the control chart will indicate whether the process is in a steady state condition and is stable and predictable or is not random or predictable and therefore not stable.

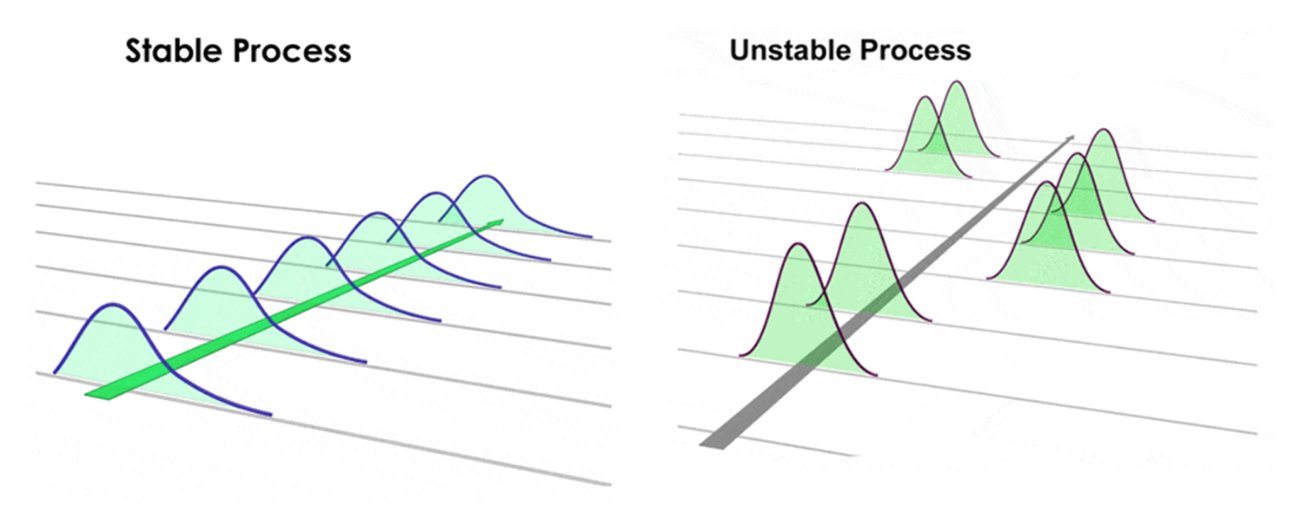

Here is a graphic illustrating a stable and unstable process:

Stability only indicates whether the process is consistent or not. Capability describes whether your stable process is capable of meeting your customer specs or internal expectations and targets. Since process capability looks at future performance, the process must be stable before you can assess capability.

Now we can answer the question of why your doctor may keep you waiting in the waiting room or why you need to fast before taking a blood test. Your bodily functions are a process. To understand what your process is doing, you must start with a stable process.

Waiting in the waiting room will give you a chance to calm your nerves and start to attain a steady state condition for your body. Likewise, fasting for 24 hours allows any special cause variation to be reduced and your process to stabilize so the test can accurately measure your process.

Stability vs. Capability

So, are stability and capability the same thing? Stability is just the means of achieving consistency in a process. It can result in good or bad outputs, depending on the current state of the process. Capable processes routinely meet quality standards or other performance metrics you’ll use in your organization.

An Industry Example of Stability

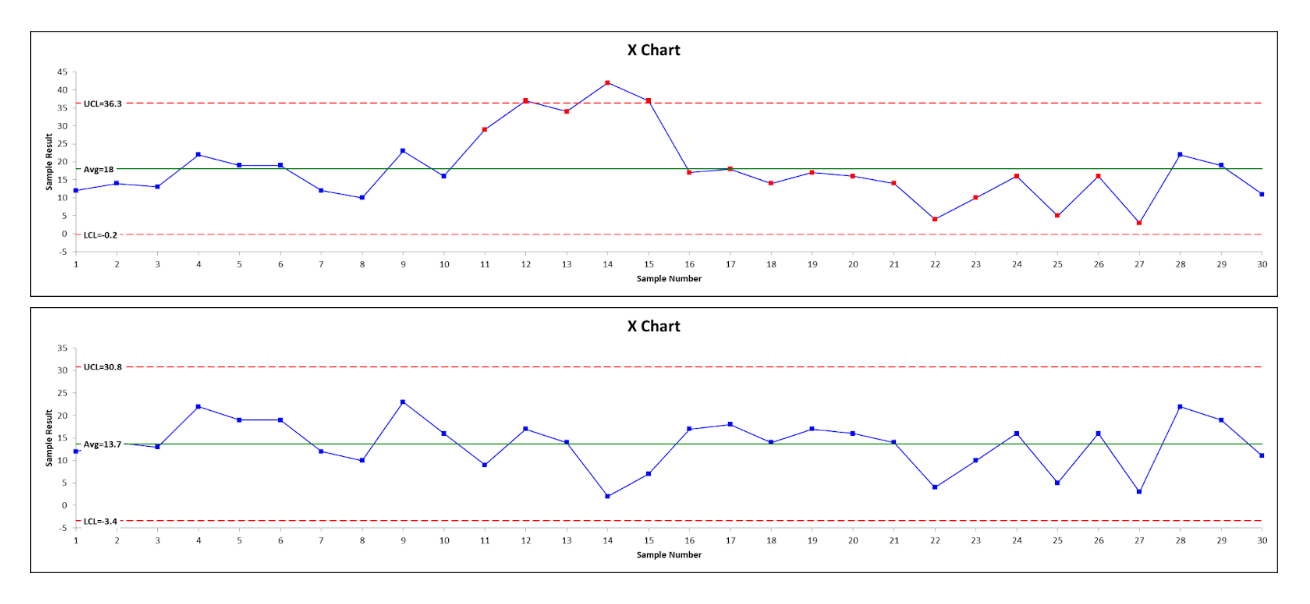

Below you see two control charts. The first one shows signs of special cause variation and would be defined as an unstable process. After making some process improvements, the second control chart shows only common cause variation and stability.

Other Useful Tools and Concepts

If you’re looking to more closely understand how your processes are doing, you’re in the right place. Learning how to construct an X-bar and R-control chart is a fantastic way of seeing exactly how your processes are performing.

You might also do well to learn about trend analysis tools for your data. No one can tell the future, but these tools use historical and current data to paint a picture that shows what your organization’s next steps might be.