Key Points

- Rework is any action that makes a non-conforming output conform to given specifications.

- It takes up time and resources to perform rework.

- Rework can impact team morale and employee satisfaction.

Customers typically only care for the product or service they receive, not for how much effort it took you to make it happen, nor how many times you had to change or rework it to get it right.

Understanding what rework is and — crucially — how to avoid rework activities makes perfect business sense. Let’s explore further.

What Is Rework?

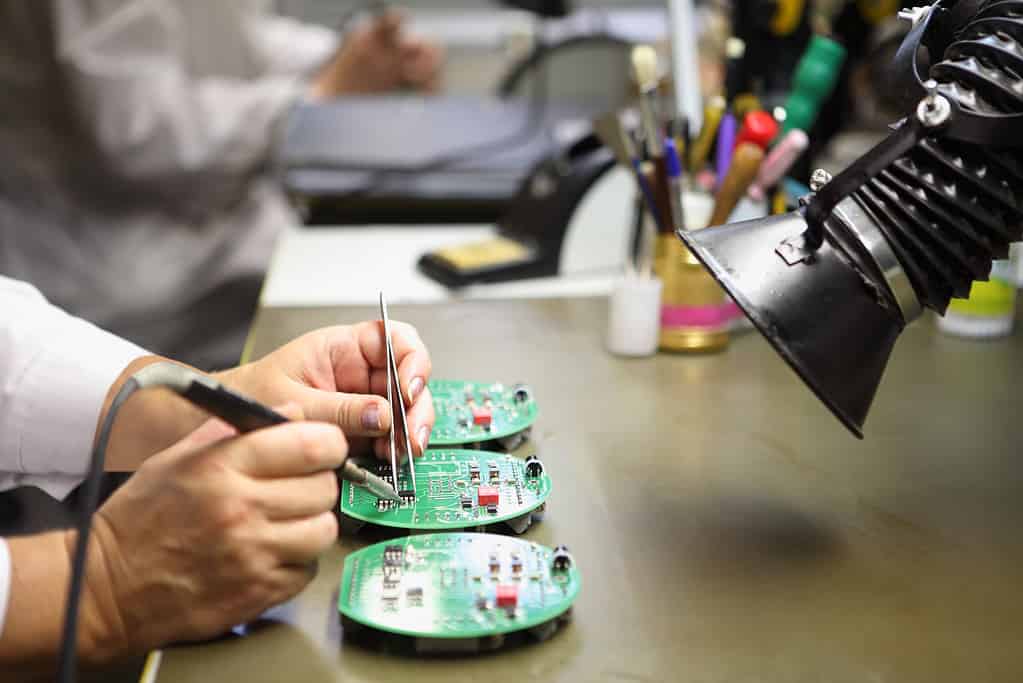

©Perfect Angle Images/Shutterstock.com

Rework is an action performed upon a non-conforming product or service that, when completed, makes it conform to its requirements. Rework can include activities such as:

- Disassembly

- Part replacement/modification

- Reassembly

Crucially, after the rework activity is complete, the functional specification and requirements are fully met.

In the context of the 8 wastes of lean, if we produce a defective (non-conforming) product or service, we can either rework or we can scrap. If we choose to rework, all of the associated activity required to return the product or service to conformance is non-value-added. The customer does not recognize, nor is willing to pay for these rework activities. The associated costs, often termed the costs of non-conformance, are absorbed by the supplier with a negative impact on profitability.

Often the terms rework and repair are used either incorrectly or interchangeably. The key differences between rework and repair are subtle but important to understand:

- Rework: An action on a non-conforming product or service to make it conform to its requirements

Example: An automotive tire should be inflated to 3 bar pressure and be free from damage leading to deflation. The tire was found to be inflated to 2.7 bar and free from damage, a rework activity inflated the tire to 3 bar pressure, and the tire conformed to its requirements.

- Repair: An action on a non-conforming product or service to make it acceptable for the intended use

Example: An automotive tire should be inflated to 3 bar pressure and be free from damage leading to deflation. The tire was found to be inflated to 2.2 bar with a nail embedded. A repair activity removed the nail, applied a patch, and inflated the tire to 3 bar pressure. The tire was then acceptable for the intended use.

Drawbacks and Benefits of Rework

Reducing, or even better, eliminating, the need for rework is implicit in a Lean Six Sigma approach. Let’s explore some drawbacks of rework — and even think about a potential benefit.

It Costs Significant Resources

Fixing something to meet its functional requirements that should have been right the first time takes valuable resources and disrupts your process flow. Your downstream customer just wants the right product, process, or service, and every time you rework to meet the requirements adds no value to the output.

It Can Reduce Customer Satisfaction and Loyalty

Rework before delivery to the customer (sometimes called internal rework) is damaging to your costs and staff motivation. Often even more damaging is rework after delivery to the customer (sometimes called external rework). Here we have both the impact of costs to rework and of reputational damage, with the likely outcomes being reduced customer satisfaction and loyalty.

It’s an Opportunity to Improve Robustness

Is there a positive to be had from rework activity? Yes, but only if we use this as an opportunity to better understand our products and processes. We can redesign or reconfigure to reduce the probability of non-conformance and, therefore, improve our robustness.

Why Does Rework Matter?

Do it once, and do it right. Easy to say, but for complex, real-world products and processes, rework can become unavoidable. Let’s investigate a little deeper.

It Lets You Know Something Is Wrong With Your Workflow

We should not accept rework as a natural outcome of our product, process, or service. Fundamentally, something is either wrong or not well-optimized, and we need to explore where and why this is occurring so we can implement changes.

It’s Bad for Costs and Your Bottom Line

Rework is fixing something that should have been done right the first time. It takes time, it disrupts process flow, and it’s a non-value-added activity. All of this is an unnecessary additional cost that strips out your profit margin.

It Demotivates Staff

Do you fancy working on the rework line this week? It can be hugely demotivating to process and rework products, and this can quickly remove any sense of pride employees have in their jobs. It’s a far better use of your staff to understand and fix the root cause of your rework activity.

Is Rework a Waste?

When factoring it into Lean methodology, it is a waste. However, it can be a necessary component for any production line. While the prospect of doing rework can be damaging to company morale, it is more important to maintain customer trust in the long haul.

An Industry Example

A large, Tier 1 supplier to the rail industry was awarded a new contract for the supply of hub bearings. The bearing technology was new but had performed well through durability and functional testing based on prototype test parts. Through prototype production, the final assembly process was developed and optimized, eliminating the need for costly rework activities.

Shortly after full-scale production commenced, there were a number of non-conforming bearings being rejected in the final assembly line. A Six Sigma black belt project was authorized to understand the reasons for the non-conformance and return the line to both capacity and capability.

Due to the volume of parts required by the customer, it was necessary to install a temporary inspection and rework line adjacent to the final assembly line. The costs associated with inspection and rework were significant, but none of the costs could be passed on to the customer.

With careful consideration and investigation into the assembly process and reviewing the Process FMEA and critical control characteristics, it was possible to determine the root cause for the non-conformance. The assembly line speed was modified allowing for assembly to be completed correctly the first time, every time, and the removal of the temporary inspection and rework line.

The cost of rework activity was calculated at $250,000 over a two-week period, and all costs were absorbed by the Tier 1 supplier.

Rework Best Practices

There are some fundamentals to get right and help us understand how and why rework can creep in. Let’s take a look at some of these.

Understand and Investigate Your Processes

It all starts with a deep understanding of your processes. Make sure you have fully captured your process inputs and outputs and that you understand where variation can occur. Revisit your failure mode and effects analysis to ensure all failure modes are captured.

Measure, Inspect, and Control the Right Things

We need to avoid unnecessary rework activity. Does your product or service meet its requirements? Are you controlling the correct characteristics to ensure these requirements are met? Time to revisit your control plan and cross-check your key process input and output variables.

Learn from Mistakes and Remove Defects

Mistakes happen, and the worst thing we can do is ignore them. If we generate products or services that do not meet requirements, we need to learn how and why this has occurred. Fortunately, we can use well-established methods such as root cause analysis to understand where things have gone wrong and reduce the probability of recurrence.

Other Useful Tools and Concepts

Are you ready for more? You might want to take a closer look at how to assess project stability. Stable processes are easier to rein in and allow for adjustment to eventually become capable processes.

Further, understanding how bimodal distributions work in the context of your data analysis can be vital. Not all data is going to be uniform, and finding differing modes can allow you to hone in on analyzing the right metrics in your data.

Conclusion

No matter what our product, process, or service is, we gain no competitive advantage by introducing and embracing rework activities. Focus on delivering things right the first time and every time, keeping one step ahead of your competition and growing customer satisfaction and loyalty.