Key Points

- Natural tolerances are used to expect deviations from a normal distribution.

- It is used in conjunction with control limits to gauge the effectiveness of a process.

- Paying attention to your natural tolerances leads to higher-quality deliverables.

“Hey boss, how important is it that our specification limit be set to 27 and 13 for this process? I really would like to have the upper limit set to 24.”

“Well, we recently estimated the natural tolerance for the system to be 26 and 14. If we use 24 it would be below our upper control limit.”

“I don’t care. The system works a lot better at 24.”

“That’s fine, but unless we can upgrade the process to meet your needs, we are going to have a lot of failures when we go to production. Failures that will cost quite a bit of money. We need to keep our specification limits outside of the natural tolerance.”

What Are Natural Tolerances?

Natural tolerances are expectations regarding deviations, represented by control limits set at three times the standard deviation above and below the mean. When in place, the limits demonstrate a 99.73% chance that any given result will occur between the given control limits. So, while it’s possible to have a result outside of the control limits, it should be statistically rare.

With these limits set three standard deviations out from the mean, if the specification limits are inside of the control limits, the users should expect consistently acceptable work, with only the rare failure. If either the upper specification limit or lower specification limit is outside of the natural tolerances, the system owners should expect more work to be outside of the specification limits, assuming the system is not influenced by special causes.

How to Calculate It

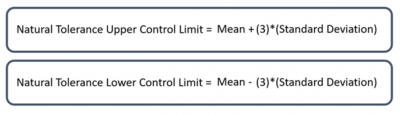

Use the following calculations to arrive at the natural tolerances:

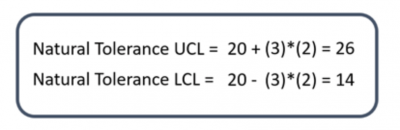

For example, the mean for a given process is 20 units, and the standard deviation for the process is two. Using the calculation, you arrive at a natural tolerance that ranges from 26 units to 14 units.

With these values, you can set the natural tolerance for the process:

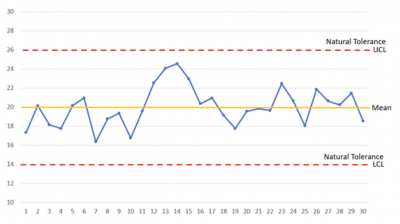

For the graph provided, the natural tolerances are between 26 and 14. Therefore, 99.73% of future values will be between these limits, providing that a special cause does not enter the equation.

If the upper and lower specification limits are set outside of the control limits, you can expect that less than 0.27% of results will be outside of the specification limits. If the specification limits are set within the natural tolerances, then more values than 0.27% will be out of specification, depending on how close the specification limits are to the mean.

For example, if the specification limits were set at 24 and 16, one would expect 5% of all values to be outside of specification, which for most processes is not set to an acceptable level. It is better to set specification limits outside of natural tolerances whenever possible.

Why It Matters

You can design near-perfect processes. However, at the end of the day, there is going to be some chaos afoot. As such, this is where a natural tolerance shines. It accounts for the drift and randomness inherent in any production and allows you to hone in on where your processes need to shine.

Benefits of Recognizing Natural Tolerances

Easy to Calculate

As shown in the example above, no difficult formulas are required to determine natural tolerances. All that’s needed to set up the natural tolerances is the mean and standard deviation for a system, which are easy to derive.

Allows for a Higher Percentage of Success

While some processes, especially those involving the safety of other human beings, might require even higher success percentages, natural tolerances set up a process with a high chance of success.

Set at 99.73%, only 3 in every 1,000 process measurements will arrive outside of the control limits. This is better than setting the limits at two standard deviations, which gets the process only to 95% and a failure rate of 50 in every 1,000 process measurements.

While the required quality levels for the process dictate where the control levels are set, many industries’ processes are set to natural tolerance levels.

Helps Identify When a Special Cause Occurs

With natural tolerances covering the chances for a result to occur that is plus or minus three sigmas away from the mean, identifying when special causes arise in the process becomes a snap.

If the process begins to see that results outside the natural tolerances are at a greater rate than 0.27%, it is a signal to begin an investigation to see what has changed in the system. Something outside the norm is occurring to cause a percentage jump outside of the control limits.

Natural Tolerance Best Practices

- The more space you can give between specification limits and natural process control limits, the better the failure rate will become. Keep in mind that widening these limits can sometimes come at a financial cost. Do not push for limits further out than the process quality needs require unless it’s financially advantageous.

- Remember that while natural tolerances work well for many processes, it’s simply not good enough for others. For example, using it for airplane maintenance would be disastrous. Having 0.27% of airplanes fail would mean over 350 planes fall out of the sky daily!

- Remember that special causes are not represented within the concept of natural tolerances. Only common cause defects are represented by the 99.73% success rate.

Other Useful Tools and Concepts

If you’re looking for some additional tips and tricks, you’re right where you need to be. Understanding how the clean point factors into your production can put you back on track to regaining customer confidence. As such, our guide covers how it works and why it matters.

Additionally, you might need to implement the use of Z Bench in your production. This handy calculation is a generic measure of how a process is performing and can be used with every step of your production line.

Conclusion

Natural tolerance is a fiscally feasible way of setting up common cause failure rate expectations on a process. It sets the upper and lower control levels up for the low failure rate of 0.027% so that when we see an increase above the expected failure rate, we know it’s time to start looking for special causes.

While it does not work well for every process, like those requiring much higher success rates, for many processes, it’s the sweet spot for economical quality control.