© Ground Picture/Shutterstock.com

Key Points

- Low-hanging fruit are high-impact decisions that require minimal effort to implement.

- Successful use can see a positive impact on any organization.

- It is industry-agnostic, meaning it can be applied to any business sector or area of your organization.

“Low-hanging fruit” – this is just more business mumbo jumbo speak, right? Wait a minute. If we can identify some high-impact actions that can help us transform our business with relatively low effort, why wouldn’t we? Welcome to your new friend: the low-hanging fruit of your business.

What Is Low-Hanging Fruit?

The term low-hanging fruit has been used in business and continuous improvement programs from the 1980s to the present day, and it refers to activities or projects that have been deemed to deliver a high positive impact with relatively low effort.

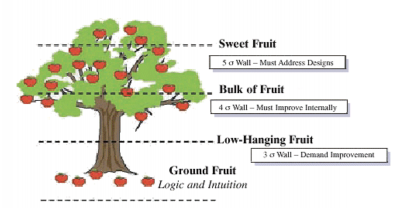

Low-hanging fruit symbolizes the lower branches of a tree, where the fruit is within easy reach or easily picked. Often we see this visualized as shown in the graphic below:

Image ref: What To Do When The Low-Hanging Fruit Is Gone

Determining what is low-hanging fruit and what improvement tools are appropriate to apply is crucial to successfully realizing the true high-impact benefits of low-hanging fruit. Individuals may have strong views on improvements they wish to address within their immediate work areas, and usually, resources that can be deployed to continuous improvement activities are limited.

The Low-Hanging Fruit Matrix

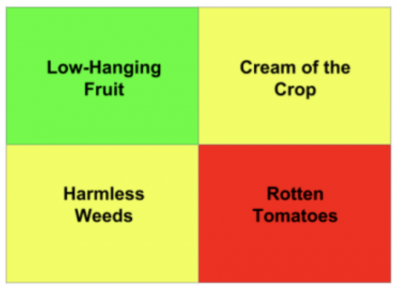

To help cut through these issues, the low-hanging fruit matrix is a useful tool for teams to utilize, helping to visualize and agree on the priority items. The matrix is often represented as shown in the graphic below:

Image ref: Low-Hanging Fruit Matrix – Lean Six Sigma for the Office

The interpretation of the matrix and the four quadrants is important for the team to understand, these are summarised as:

- High Impact / Low Effort: The projects that are low-hanging fruit.

- High Impact / High Effort: The cream-of-the-crop initiatives. While the effort is considered by the team to be high, these projects are considered worth the effort and should be pursued. They may require a significantly longer time or more resources to realize the benefit.

- Low Impact / Low Effort: The harmless weeds that can be considered, but not pursued at the expense of low-hanging fruit.

- Low Impact / High Effort: The rotten tomatoes that the team should avoid.

Each team member will consider the impact that the improvement will have on the business, rating high or low, and also the effort required to deliver and implement the improvement, again rating high or low. Consensus is gained across the team, often helped by the use of a dedicated facilitator.

With low-hanging fruit identified and agreed upon, the team can concentrate on the improvement actions and tools necessary to deliver these activities. Classic examples of tools that are often deployed to address low-hanging fruit can include Root Cause Analysis and 5S, in addition to reviews of process maps.

Can You Always Pursue Low-Hanging Fruit?

You certainly can focus on the areas where minimal effort is needed to make improvements. However, that’s putting the cart before the horse. You want to have other tools in place to continue your cycle of improvement. While it is tempting to focus on the easiest areas of improvement, that isn’t sustainable.

Benefits and Drawbacks of Low-Hanging Fruit

Low-hanging fruit can deliver powerful business improvements with economical use of resources, but it’s not always plain sailing. Let’s look at some benefits and drawbacks.

It Focuses on High-Impact Choices Within a Limited Set of Parameters

If you want to make quick progress with a limited pool of resources to draw from then identifying low-hanging fruit is a great way to start your continuous improvement program.

Relevant Across All Business Areas

It doesn’t matter if you work in an office or production line environment, the principles of identifying low-hanging fruit and applying quality tools and processes to address these are equally applicable and rewarding.

It Is Easy to Fixate on Low-Hanging Fruit

Be careful not to look for and to only address those high-impact and low-effort items. Once they are gone, the momentum and enthusiasm for continuous improvement can easily be lost, and disillusionment can set in.

Why It Matters

By understanding what low-hanging fruit means, and the opportunities it brings, you can make good use of valuable team resources.

It Can Deliver a Significant Positive Impact to Your Business

In a sentence, this is exactly why there is value in understanding and addressing these high-impact and low-effort activities. Whether it’s product quality, customer satisfaction, or internal process time and rework, addressing low-hanging fruit gives you a positive boost.

It Reinforces the Use of Quality Tools

The high-impact and low-effort activities that deliver tangible benefits are perfect examples to reinforce continuous improvement in an organization. The use of quality tools such as 5S can deliver quick results that build confidence and trust for future deployment with employees.

Builds Team Collaboration and Employee Satisfaction

We don’t often deploy one person to find and fix quality issues or deliver continuous improvement. Understanding and addressing the low-hanging fruit is a team game; it builds collaboration with clearly defined goals and relatively quick, positive outcomes that employees can celebrate together.

An Industry Example

An automotive Tier 1 supplier had recently expanded its portfolio to include the manufacture and assembly of variable displacement oil pumps. The new production and assembly lines were variations of designs used in other manufacturing plants and had been operational for two months. As part of the continuous improvement program, a production line walk was conducted once a week for one month, led by the manufacturing and quality team to review and capture all opportunities for potential improvement and efficiency.

The manufacturing and quality team had previous experience of using a low-hanging fruit matrix to qualify the potential improvement actions and agreed to use this approach. A Six Sigma Black Belt was nominated as the team facilitator, and two sessions were held to capture all of the opportunities for potential improvement and efficiency, with each being discussed for high or low impact and high or low effort.

The high-impact and low-effort items, the low-hanging fruit, were taken as the initial activities to pursue. These included some simple time and motion studies for resource optimization and 5S checks to ensure standardized work was deployed. Upon completion of the low-hanging fruit activities, the production line walks were repeated, any new items were added to the low-hanging fruit matrix, and the team then moved focus to the longer-term, higher-effort activities.

Low-Hanging Fruit Best Practices

To deliver the true benefits of low-hanging fruit, there are several best practices to consider. Let’s explore three of these.

Get the Team Together

One person’s low-hanging fruit can be another person’s rotten tomatoes. Whilst individual perspectives and actions can be useful, it’s far more powerful to get a team together to look across the business and agree on the high-impact and low-effort activities. Use a facilitator to keep the team on topic and deliver results.

Be Realistic About What Can Be Achieved

Without a clear scope, any type of continuous improvement activity can be overwhelming and risks failure. Use the principles of SMART to help define the task and scope, and assign suitable resources to investigate the items believed to be low-hanging fruit. After initial evaluation, don’t be afraid to reclassify if the impact or effort changes.

Plan Beyond the Low-Hanging Fruit

There is life beyond low-hanging fruit and the use of tools such as the low-hanging fruit matrix is useful to help plan and successfully resource continuous improvement activities. Stopping at the lower branches of the fruit tree means all of the rest of the fruit is available and untouched, often for your competitors to take advantage of.

Other Useful Tools and Concepts

Looking for something else to help your organization along? You might want to take a closer look at the likes of COPIS. While this is similar in concept to the SIPOC diagram it puts the customer first. As such, it yields impressive, but differing results when you’re going about your process improvement cycle.

Additionally, learning how to handle rework in a business is paramount. No production line is perfect, so having the controls in place to rectify and mitigate issues is going to maintain customer trust.

Conclusion

Whether you are starting in continuous improvement or a veteran in the field, the identification and resolution of low-hanging fruit brings a significant positive impact to your organization with relatively low effort. It can be a winner all around.

The image featured at the top of this post is ©Ground Picture/Shutterstock.com.