The director of business development sat in the CEO’s office with a weary face. “You don’t understand, boss. I’ve thrown every tool at my disposal to get this customer to order the new product. They want the product. It is exactly what they need.”

“So, why is this a problem? Why won’t they sign the contract?”

“Because of our past performance. The current product we sell them continues to this day to have quality problems. One in four products have to be returned for repair within the first year in service. The numbers were worse two years ago, when we launched the product. To put it in simple terms, they just don’t trust us to deliver a quality product.”

“Tell them we will beef up our warranty. Tell them we will send out service techs to repair the product on-site.”

“The customer doesn’t want us to have better repair processes. They want us to deliver a product on time that works the first time. It’s too late, boss. Our competition is on schedule to have a similar product in four months, and the customer is going with them. Our competition’s products don’t have the same quality issues. The customer trusts that the competitor’s product will work right the first time.”

An overview: What is cost of poor quality (COPQ)?

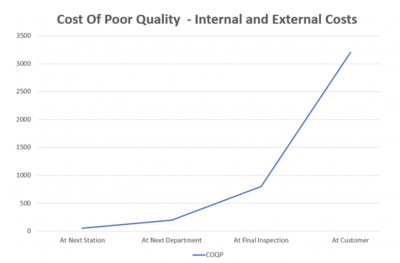

Cost of poor quality, or COPQ, is both the direct and indirect costs associated with the defects generated by a process. The cost varies depending on how far the product or service goes along the process before being detected.

These costs can be calculated by determining what was required to repair the defect and what was impacted within the main process flow when time and resources had to be spent on the repairs.

When an error is detected immediately, the cost is typically smaller. The repair does not involve much disassembly, or multiple departments, and the tools for repair are often present.

Once a part or service moves on to a different department, it becomes more expensive to fix. More disassembly may be required. Multiple personnel may be required. More time and coordination will be required. Still, the cost of finding an error at this point is often manageable, though not preferred to immediate identification.

The levels of cost and coordination increase greatly if the problem is not detected until right before the handoff to the customer, which can see the repair costs skyrocket.

The worst possibility is when the defect makes it all the way to the customer, which is when the costs increase exponentially. Now it may be required to send out a technician to repair the defect at the customer’s location, or the product may have to be returned to the point of manufacture to perform the repair. Preparations for transport can be quite high in addition to the required repair costs.

The most damaging cost is when defects change the customer’s opinion of your product or service’s brand. When they associate your work with poor quality, it tarnishes your brand name, which lowers the perceived value of your work. If the customer starts associating your brand with poor quality, they may begin to reach out to your competitors, and you may lose business.

3 benefits of attending to COPQ

Reduce total cost

The sooner the defect of a product or service is detected, the less costly it is to make the repair. If a defect is found at the end of the production process, it may be a cumbersome process just to disassemble the product and reach the defect, making the effort expensive to repair. Defects that make it to the customer are the most expensive, as they include the possibility of eroding customer confidence in the brand.

Reduce lead time

The sooner a product with an error is detected, the faster it becomes to perform the repair. If a defect is found at the end of the production process, the product may need to be disassembled, taking additional time and resources that could be used in making a new product. If a defect is found at the customer, even more time is needed to make the repair, as the product must be sent back, or a repair technician must be sent to the customer’s location.

Satisfied customers

As a customer, you do not want to waste your time dealing with a brand that has a poor quality reputation. By detecting and resolving the quality issues prior to customer delivery, the only experience the customer has with the product is one when it always works.

3 best practices when trying to lower your COPQ

- Always remember that while quality initiatives will minimize your defects, it’s rare to reach zero defects over time. Be sure to put the right processes in place that help identify the error as early as possible. These additional verification steps have a cost, but the cost should be far less than the cost of the error going undetected until later in the process.

- If a new product has been moved into production too soon and is experiencing multiple or critical defective issues, you should take immediate action to assign the personnel needed to address the issues before moving on to future projects. Otherwise, you are taking a large risk regarding repair costs and the reputation of your customers.

- It can be a challenge calculating all of the separate hard and soft costs connected with the COPQ for a project. While you should be as exact as your data allows you to be, don’t get upset if some of the data is approximated. Getting an understanding of what the ballpark savings will be is the goal. Actual savings, once an improvement has been in play for a given time, will never perfectly match your estimated savings for the project.

Frequently Asked Questions (FAQ) about cost of poor Quality

What are some examples of COPQ?

There are the obvious costs relating to the direct reworking of the product, such as reducing error rates that result in the reduction of rework (internal) or claims (external). In addition, there are a lot of indirect cost examples to consider. Some are design costs, such as having to make a design change to avoid the error in the future. Some are resourcing costs, such as taking resources from a different design project to address the defect. The worst loss is that of brand recognition, and the possibility of the customer going to the competition.

Preventative programs can be costly. Can I eliminate them and call that a cost savings?

Preventative programs do have a cost, but when done correctly, they are less costly than the defects they are trying to avoid. It is key to try and calculate the cost of poor quality, then compare them with the cost of preventative programs, programs such as material testing initiatives and proper employee training. If the preventative program is more expensive, then consider a way to restructure them to be less expensive. In most situations preventative initiatives should be more affordable than dealing with defects since they avoid the creation of defects.

Should only hard savings be considered COPQ?

Different managements will put differing weights on hard cost savings and soft cost savings. Some companies like to ignore soft costs altogether, but this is not recommended. While everyone likes to see the hard savings, as they are easier to prove out, soft savings should at least be recognized as existing.

For example, a new project just eliminated the need for a new storage addition. If the money for the new storage addition was not already allocated in the budget, then the elimination of the storage addition is considered a soft savings. This savings will not show up on the bottom line. Still, if the project were not performed, the requirement of the storage addition would have remained, so the fact that the project eliminated the need to perform the addition should be recognized.

COPQ can range from minor financial waste to loss of your customers

Cost of poor quality demonstrates how the defects in your process directly connect to your business financial situation. When detected and addressed near the source of the defect, financial losses can be minimized. To allow defects to reach your customer, is to risk having your customers reach out to your competitors in search of defect-free products or services.