From the inception of iSixSigma Magazine, a regular feature of the publication has been exclusive research on aspects of deploying Six Sigma. The topics benchmarked have ranged from “Black Belt Return on Investment” in the inaugural issue, January/February 2005, to “The Lean Six Sigma Toolset” in November/December 2009. In addition, the magazine reports each year on the global salary survey that iSixSigma conducts as an industry yardstick.

In the magazine’s fifth anniversary issue, we looked back at some of the research highlights by organizing findings into the following categories: projects, training and development, tools and methods, financial benefits, and culture change.

Over the next few weeks, we will be sharing this benchmarking data with iSixSigma.com readers. Part 1 highlighted project data; Part 2 looked at training and development data. In Part 3 the focus is tools and methods data.

Tools and Methods

We all know a Lean Six Sigma initiative is so much more than just a set of tools. But the tools cannot be ignored when looking at the workings of any business process improvement initiative. The proper tools used the right way give practitioners power to make lasting change. The following findings dive in to the tools used in Lean, Six Sigma and innovation.

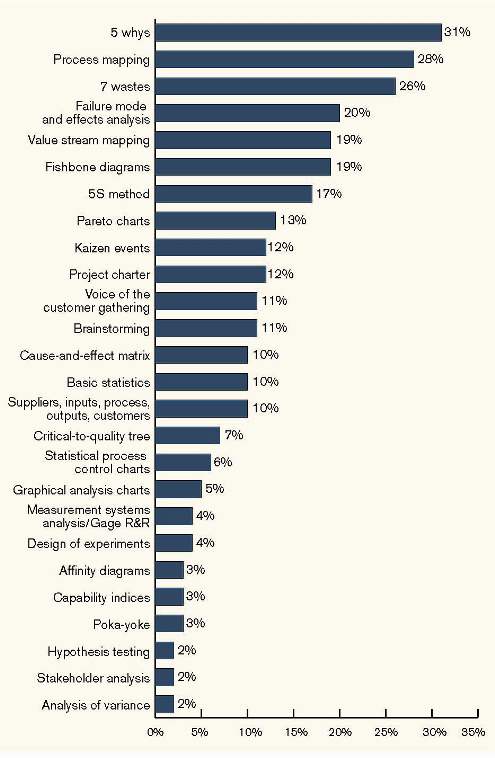

- The three tools that are considered to be fundamental when starting a process improvement program are 5 whys, process mapping and 7 wastes. From “The Lean Six Sigma Toolset,” November/December 2009

- Brainstorming is by far the most popular tool that companies use for innovation. Design for Six Sigma and Design for Lean Six Sigma are also widely applied. From: “The Next Big Thing: How Companies Innovate,” July/August 2007

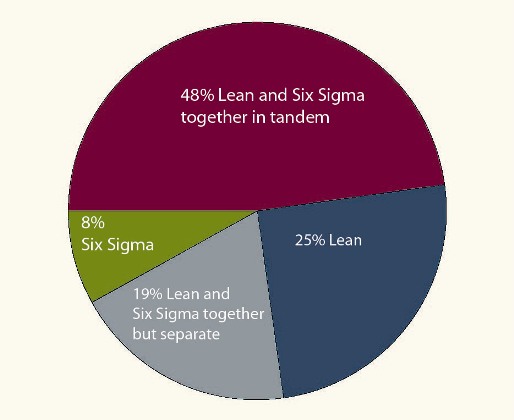

- Increasingly Lean and Six Sigma are used in tandem. Only a small percentage of companies use Six Sigma as a stand-alone methodology. From: “Lean Benefits and Challenges,” September/October 2009